Oil-gas separation cylinder, oil-gas separation device and oil chromatography

A separation device and separation cylinder technology, applied in the direction of material separation, measuring device, separation method, etc., can solve the problems of complex structure, poor effect, long time spent, etc., and achieve the effect of simple structure of the device and enhanced degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

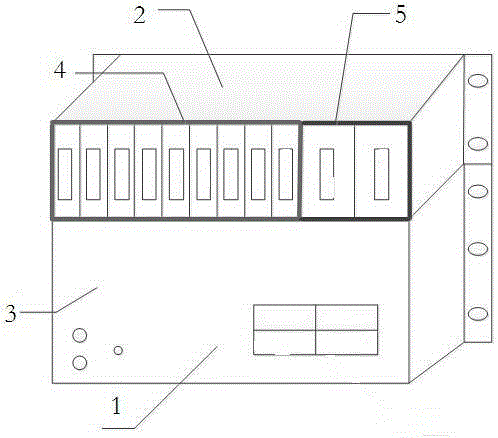

[0019] The structural representation of the embodiment of a kind of oil chromatography is as figure 1 As shown, it includes transformer oil extraction and oil-gas separation layer 1 and transformer fault gas analysis and diagnosis layer 2. Transformer oil extraction and oil-gas separation layer 1 includes oil-gas separation module 3, chromatographic column and semiconductor detector; transformer fault gas analysis and diagnosis layer 2 includes fault analysis module 4 and power supply module 5, fault analysis module 4 includes communication, fault analysis and CPU plug-in for data storage, three outlet plug-ins responsible for controlling each component, expansion plug-in for power outlet expansion, DC plug-in for DC signal acquisition and processing, and DC signal processing and sending the DC signal to the CPU in the form of a bus The collection plugin for plugins. Among them, the fault analysis module 4 is based on the concept of VLD visual programming control to realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com