Automatic insulation detection system of constant-speed motor

A detection system and automatic technology, applied in the direction of electric motor generator test, test dielectric strength, etc., can solve the problems of motor insulation change, difficult to find, etc., achieve the effect of avoiding accidents, wide application range, and improving technical management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

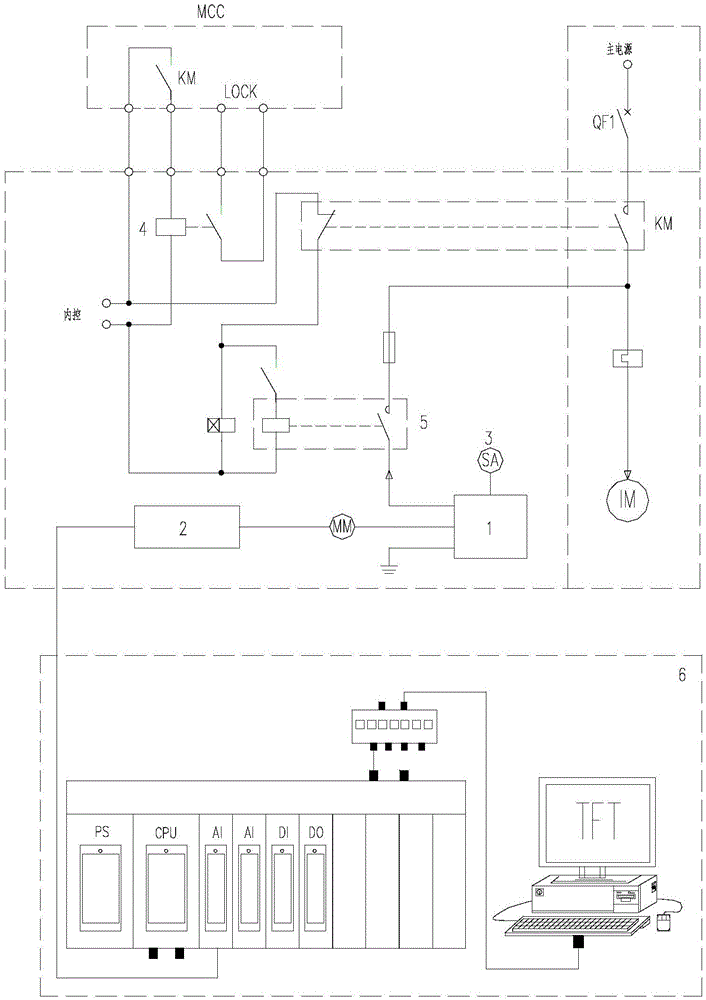

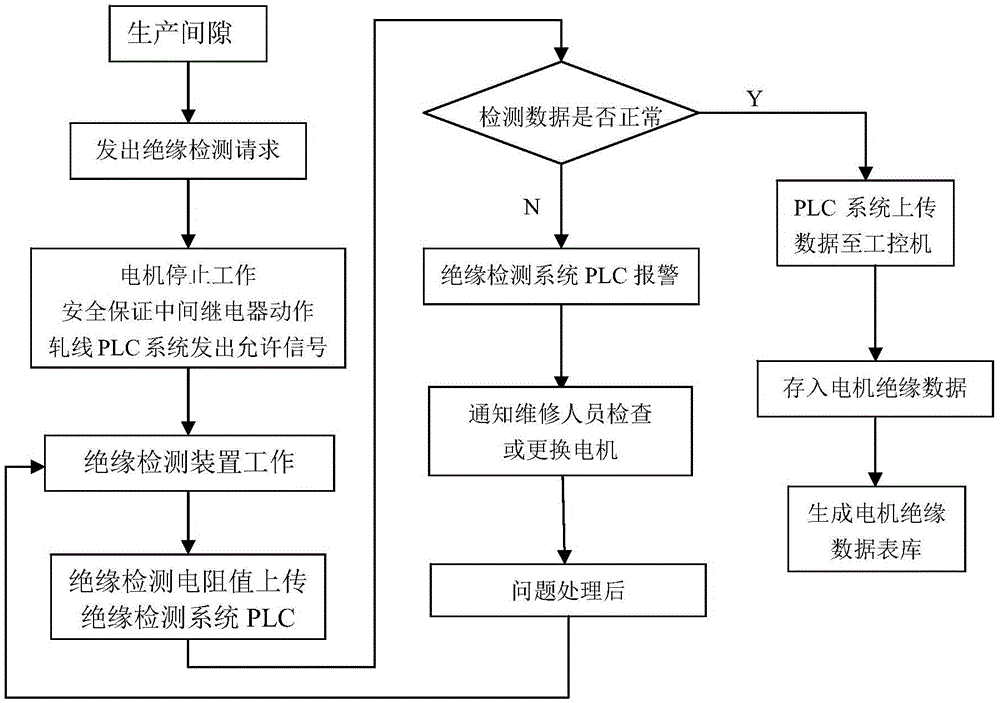

Embodiment 1

[0031] Set the motor to be detected on the screen of the PLC control and data acquisition system and the database 6, and realize the motor insulation detection through the insulation detection manual automatic transfer switch 3, the main circuit safety guarantee intermediate relay 4 of the constant speed motor, and the motor insulation detection working contactor 5 For the conduction of the circuit, the motor to be detected is detected by the motor leakage current signal acquisition device 1, and the detected signal is converted into an analog signal that can be uploaded by the measurement signal transmitter 2, and uploaded to the PLC control and data acquisition system And the database 6, through the PLC control and data acquisition system and the database 6 to judge the acquisition signal. When the motor insulation detection value is normal, the PLC control and data acquisition system and the database 6 send a motor normal signal to the PLC system of the production line, and ...

Embodiment 2

[0033] Set the motor to be detected on the screen of the PLC control and data acquisition system and the database 6, and realize the motor insulation detection through the insulation detection manual automatic transfer switch 3, the main circuit safety guarantee intermediate relay 4 of the constant speed motor, and the motor insulation detection working contactor 5 For the conduction of the circuit, the motor to be detected is detected by the motor leakage current signal acquisition device 1, and the detected signal is converted into an analog signal that can be uploaded by the measurement signal transmitter 2, and uploaded to the PLC control and data acquisition system And the database 6, through the PLC control and data acquisition system and the database 6 to judge the acquisition signal. If there is a problem with the insulation of the motor, an audible and visual alarm for motor failure is sent on the screen of the PLC control and data acquisition system and the database 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com