Monitoring system and method for spot inspection and maintenance of mobile machinery

A mobile machinery and monitoring system technology, applied in the field of mobile machinery status point inspection and maintenance monitoring system, can solve the problem of not doing a better job in process control and process management, staying in the management and on paper, and not having effective advanced technical tools and other issues to achieve the effect of refined management, reduced management costs, and savings in management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

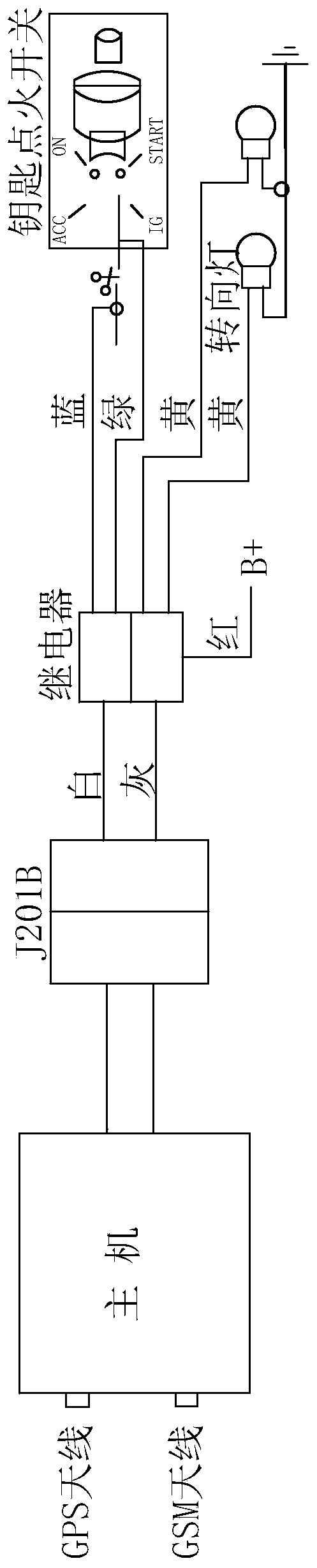

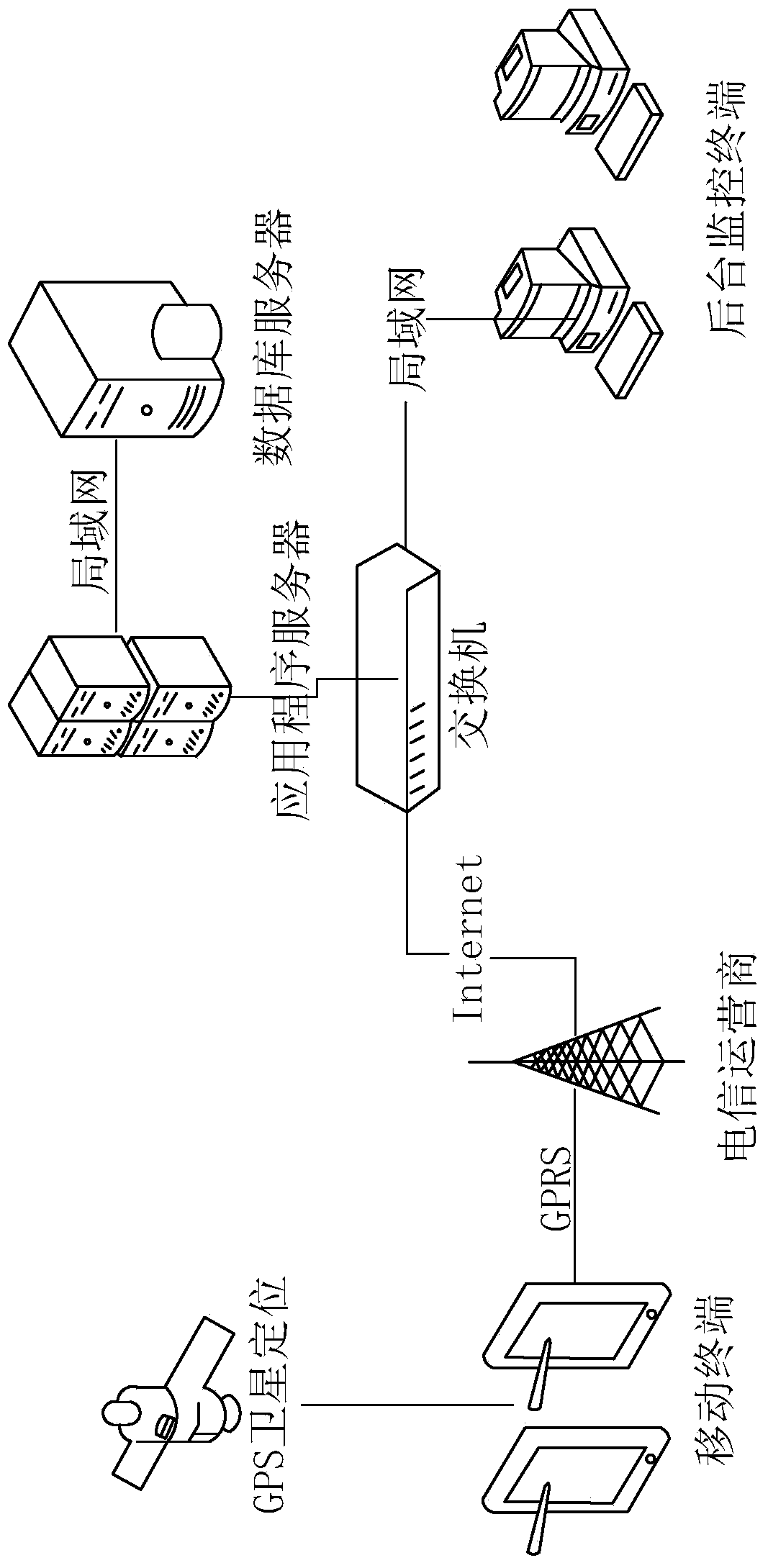

[0026] as attached Figure 1-2 As shown, the monitoring system for spot inspection and maintenance of mobile machinery status includes ACC control unit installed on each mobile machinery equipment, GPS positioning system and background monitoring system communicating with ACC control unit, mobile phone terminal communicating with GPS positioning system , a background monitoring system that communicates with both the GPS positioning system and the mobile phone terminal;

[0027] The ACC control unit includes an ACC power switch, a host connected to the ACC power switch through wires, and a GPS antenna and a GSM antenna installed on the host, and the ACC power switch is connected to the key ignition switch of the mobile machine;

[0028] The GPS positioning system receives the mobile machinery positioning information of the ACC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com