Cathode material of metal-air battery, preparation method of cathode material and metal-air battery

A metal-air battery and cathode material technology, which is applied in battery electrodes, fuel cell-type half-cells and primary cell-type half-cells, circuits, etc. performance, improved power density and stability of use, and the effect of efficient current collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention provides a method for preparing a metal-air battery cathode material described in the above technical solution, comprising the following steps:

[0071] a), the bottom layer and the core layer are pressed together, and the catalyst slurry is used to form a film on the surface of the core layer before or after the pressing, so as to obtain the metal-air battery cathode material;

[0072] The bottom layer comprises metal foam and a hydrophobic material;

[0073] The core layer includes metal foam and a hydrophobic material;

[0074] The core layer has a greater porosity and / or pore size than the bottom layer;

[0075] The catalyst slurry includes a porous carbon material, a hydrophobic material, a catalyst and a solvent.

[0076] In the preparation method of the metal-air battery cathode material provided by the present invention, the bottom layer and the core layer are pressed together, and the catalyst slurry is used to form a film on the surface...

Embodiment 1

[0112] 1) Preparation of bottom layer:

[0113] Select foamed nickel with a thickness of 1.5 mm, a pore size of 300 μm, a porosity of 70%, and a mass of 0.46 g, and impregnate it in 20 wt % polytetrafluoroethylene emulsion (Shanghai 3F Company). The metal foam impregnated with polytetrafluoroethylene was taken out, dried at 80°C for 5 hours, and then sintered at 350°C for 1 hour to obtain the bottom layer.

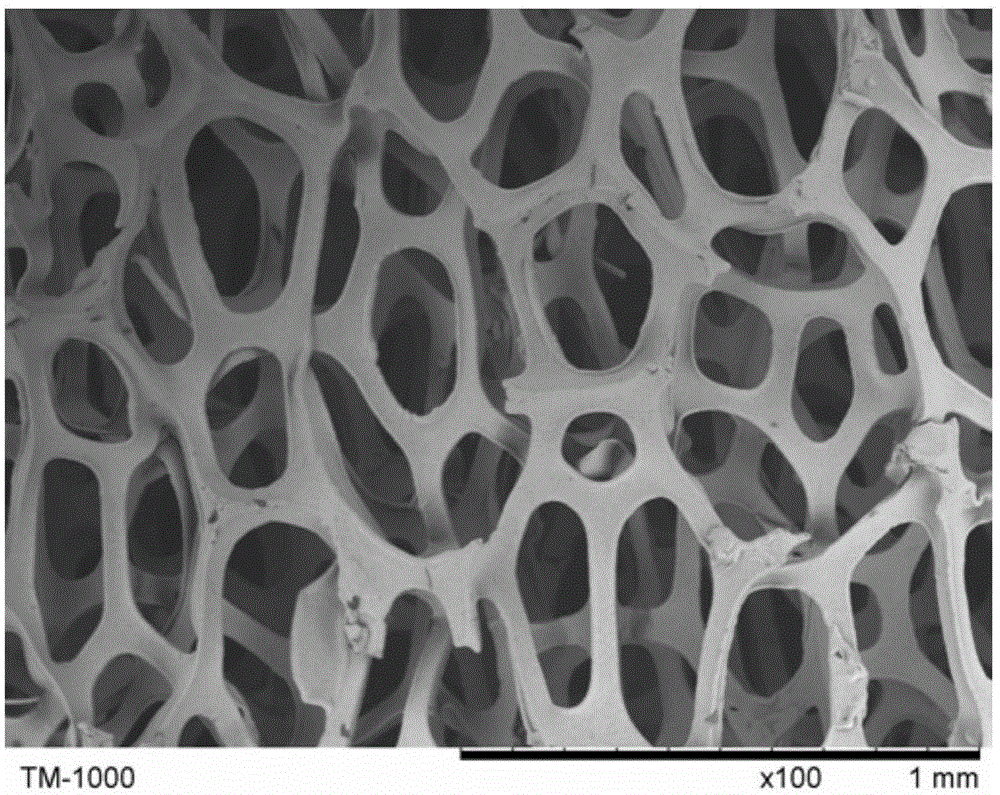

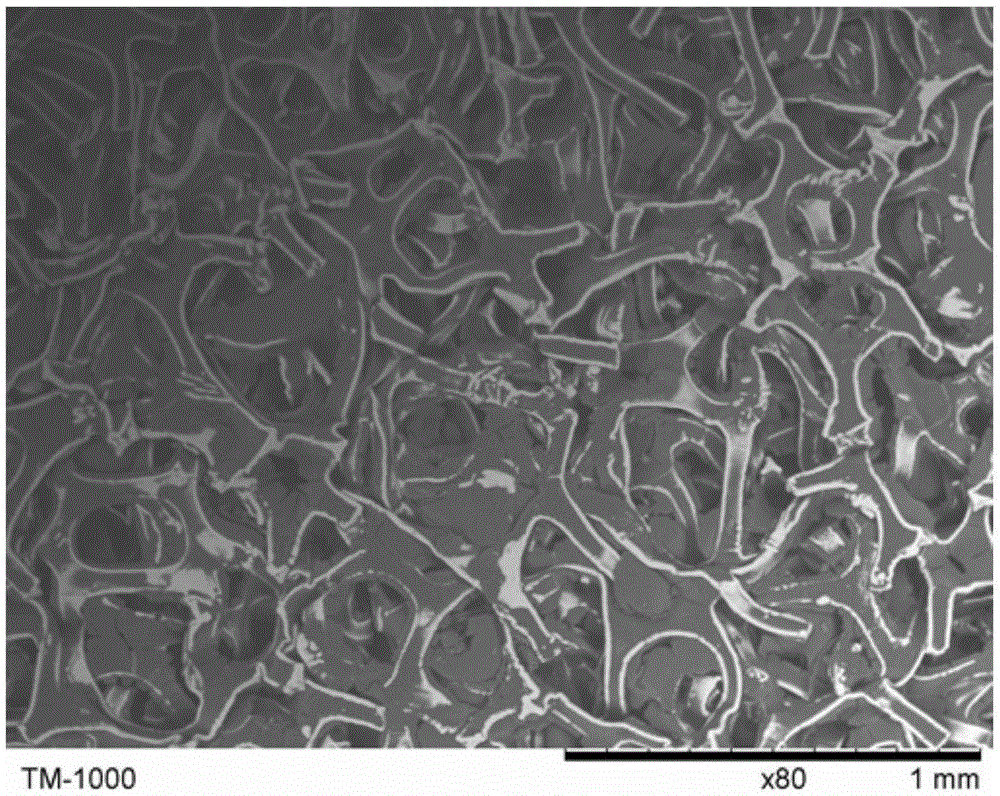

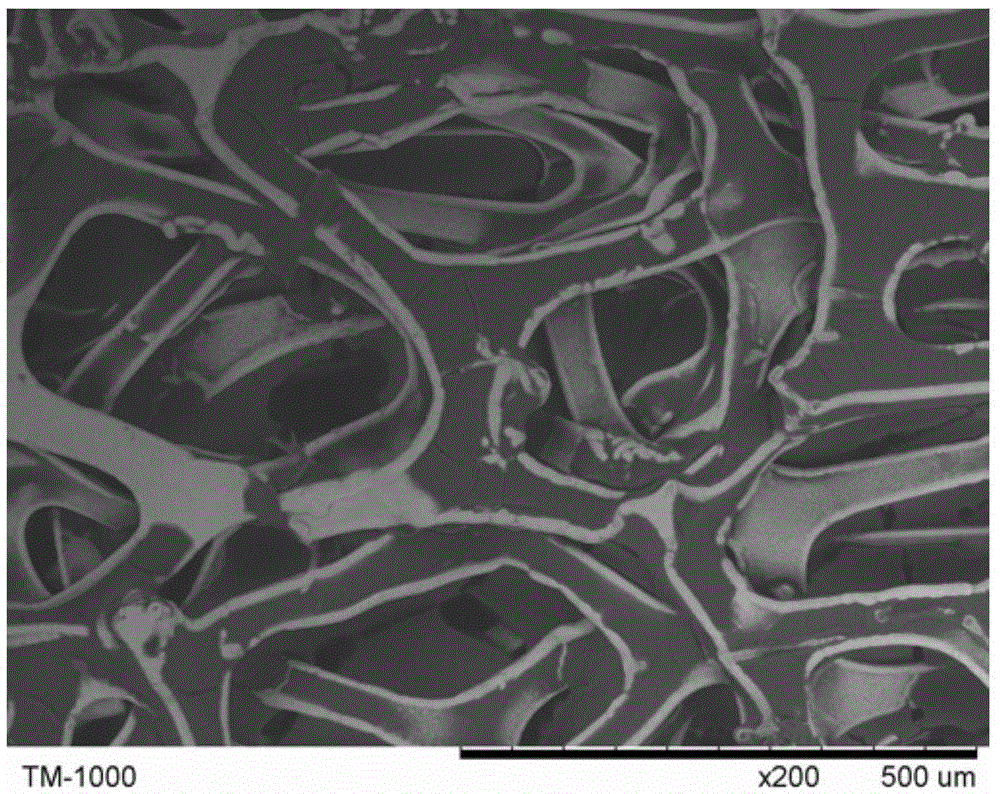

[0114] SEM observations were carried out on the non-impregnated nickel foam and the prepared core layer respectively, the results are as follows figure 1 with figure 2 shown. figure 1 The scanning electron micrograph of the nickel foam provided by the embodiment of the present invention 1; figure 2 The scanning electron microscope image of the bottom layer provided by Example 1 of the present invention. pass figure 1 and figure 2 It can be seen from the comparison that the polytetrafluoroethylene in the bottom layer provided by this embodiment has been compounded ...

Embodiment 2

[0126] 1) Preparation of bottom layer:

[0127] Select foamed nickel with a thickness of 1.5 mm, a pore size of 300 μm, a porosity of 70%, and a mass of 0.46 g, and impregnate it in 40 wt % polytetrafluoroethylene emulsion (Shanghai 3F Company). The metal foam impregnated with polytetrafluoroethylene was taken out, dried at 80°C for 5 hours, and then sintered at 350°C for 1 hour to obtain the bottom layer.

[0128] The porosity and pore diameter of the bottom layer prepared above were measured, and the results showed that the porosity was 30% and the pore diameter was 120 μm.

[0129] 2) Preparation of the core layer:

[0130] Select 0.35g nickel foam with a thickness of 1.5mm, an average pore diameter of 500μm, and a porosity of 97%, and impregnate it in 20wt% polytetrafluoroethylene emulsion (Shanghai 3F Company). The metal foam impregnated with polytetrafluoroethylene was taken out, dried at 80° C. for 5 hours, and then sintered at 350° C. for 1 hour to obtain the core la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com