A kind of pad window opening method and pcb board

A technology for PCB boards and pads, which is applied to the pad windowing method and the field of PCB boards, can solve the problems of PCB board product performance degradation, pin distortion, biased micro-electronic devices, etc., so as to improve the welding quality and prevent spillage. , Improve the effect of arrangement uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]This embodiment provides a pad window opening method, including the following steps:

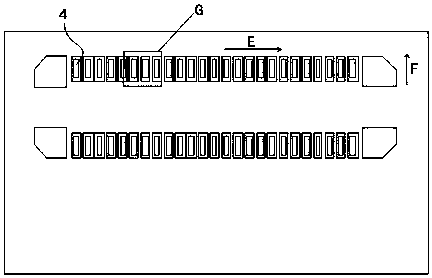

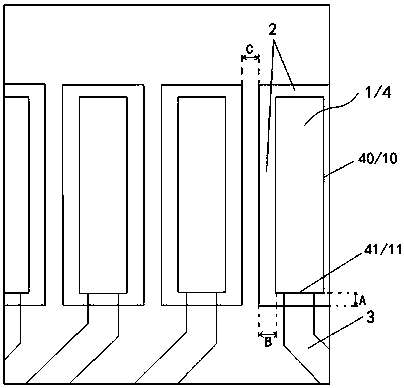

[0035] 1) Set a shading area on the film, such as Figure 1-2 As shown, the shading area includes a pad shading area 1 for covering the pad 4 and a buffer zone 2 surrounding the pad shading area 1; the pad 4 has a connection edge 41 connected to the line 3 and not The non-connecting side 40 connected to the line 3, the pad light-shielding area 1 has a light-shielding area connecting side 11 corresponding to the connecting side 41 and a light-shielding area non-wiring side 10 corresponding to the non-wiring side 40, and is set to The width A of the buffer zone where the connecting edge 11 of the shading area is the inner edge is 0.6mil, and the width B of the buffer zone with the non-connecting edge 10 of the shading area being the inner edge is set to be 2.35mil; The distance between them is 3mil;

[0036] 2) Adjust the alignment accuracy of the alignment exposure machine to less tha...

Embodiment 2

[0043] This embodiment provides a pad window opening method, which is a modification based on Embodiment 1, and specifically includes the following steps:

[0044] 1) Read the film data information containing the buffer zone 2 and the width of the buffer zone 2 is 2.4mil into the Genesis / Incam design software system. The wiring edge 10 is the buffer zone of the inner edge. In this step, adjust the width A of the buffer zone with the light-shielding wiring edge 11 as the inner edge to be 0.6mil;

[0045] 2) Adjust the alignment accuracy of the alignment exposure machine to be less than 0.6mil, and then use the alignment exposure machine to align the film with the PCB board provided with the pad 4, so that the pad shading area 1 is aligned with the pad 4 After the pads 4 are aligned, the PCB board is exposed and developed, so that the pads 4 are completely exposed, and the windowing of the pads is completed.

[0046] The pad window opening method of this embodiment is based on ...

Embodiment 3

[0052] This embodiment provides a PCB board, and the pads of the PCB board in this embodiment are prepared by using the pad window opening method in Embodiment 1 or Embodiment 2.

[0053] Since the pads on the PCB of this embodiment are prepared by the above-mentioned pad window opening method, the PCB board of the present invention has all the advantages of using the above pad window opening method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com