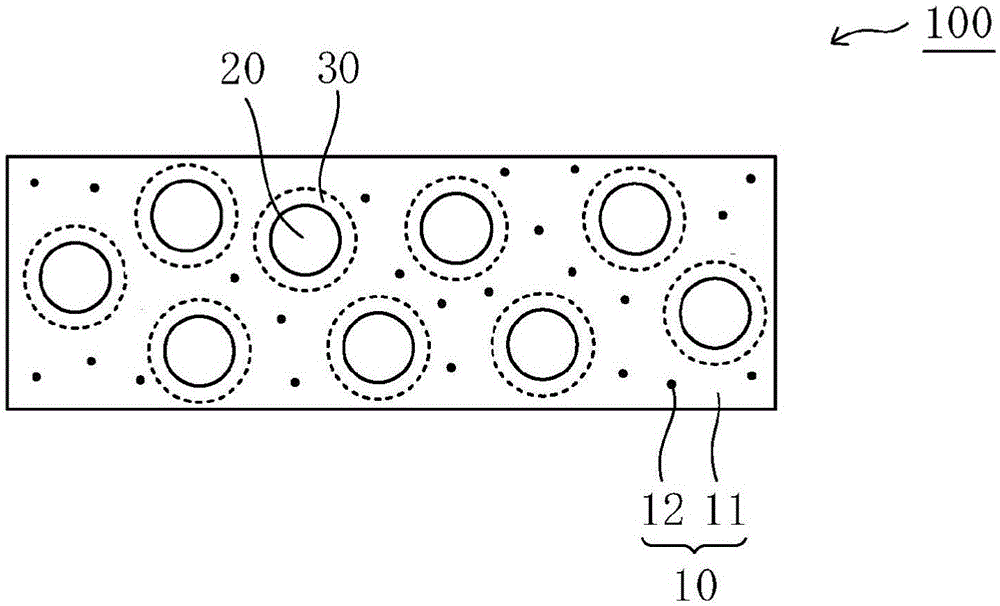

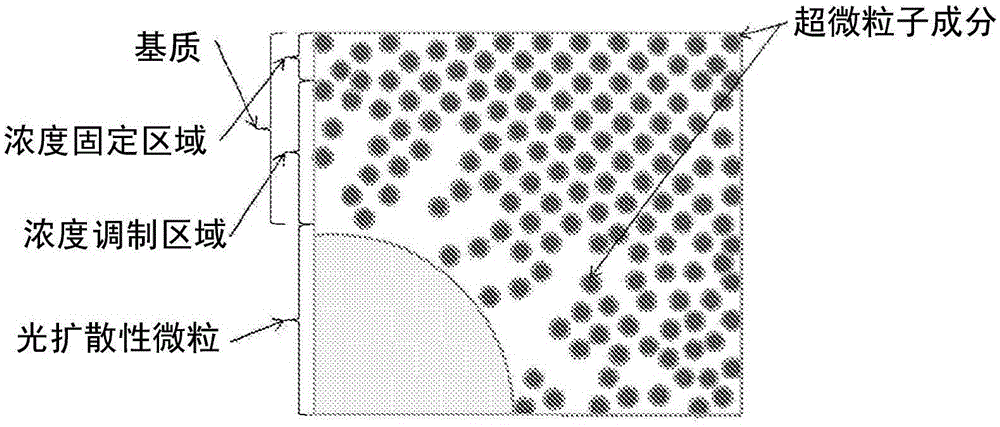

Light-diffusing element and method for manufacturing light-diffusing element

A manufacturing method and technology of light diffusion, applied in optical elements, diffusing elements, optics, etc., can solve the problems of curling, curing shrinkage, and productivity, etc., and achieve strong diffusivity, suppress back scattering, haze high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

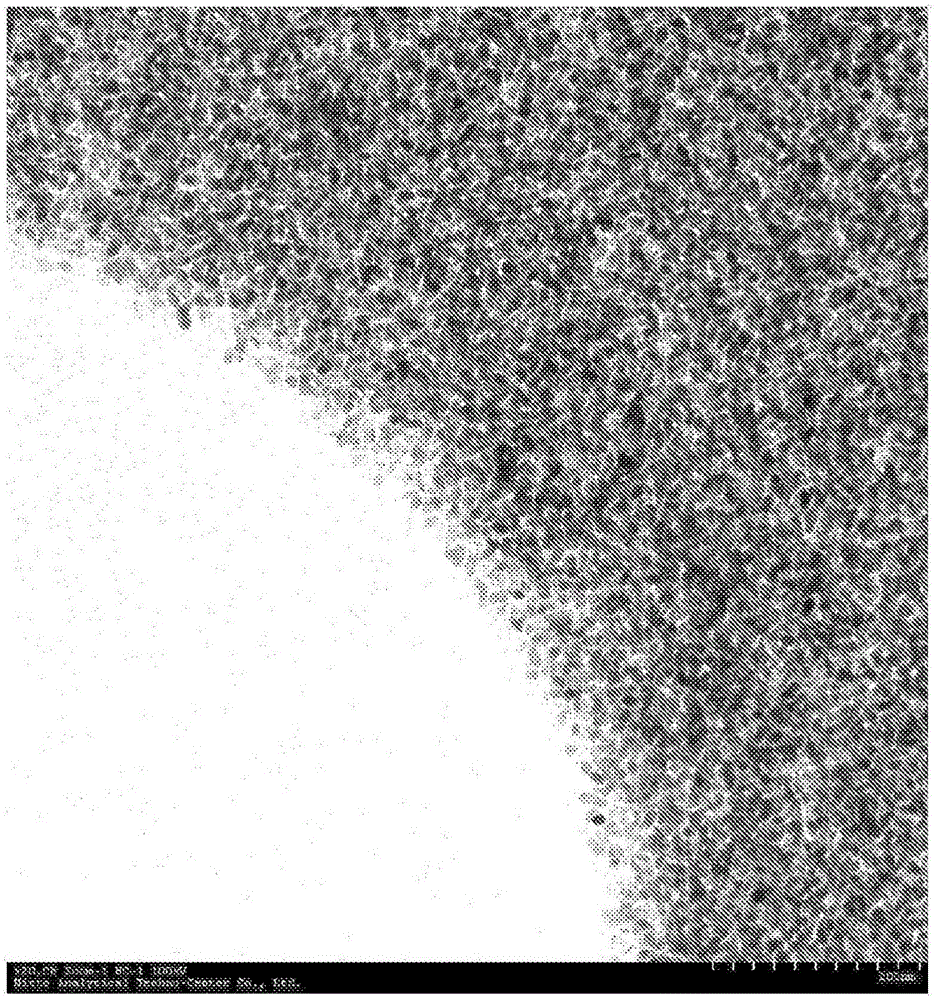

Embodiment 1

[0124] 15 parts of polymethyl methacrylate (PMMA) fine particles (manufactured by Sekisui Chemical Industry Co., Ltd., trade name "XX131AA", average particle diameter 2.5 μm, refractive index 1.49) as light diffusing fine particles, and organic solvent 30 parts of mixed solvents (weight ratio 50 / 50) of butyl acetate and MEK were mixed and stirred for 60 minutes to prepare a mixed liquid.

[0125]Then, to the obtained mixed solution, a resin for hard coating (manufactured by JSR Corporation, trade name "Opstar KZ6661" (containing MEK / MIBK)) 100 parts, 50% butyl acetate solution 11 of pentaerythritol triacrylate (manufactured by Osaka Organic Chemical Industry Co., Ltd., trade name "Viscoat #300", refractive index 1.52, molecular weight 298) as a precursor of the resin component 0.5 parts, 0.5 parts of a photopolymerization initiator (manufactured by Ciba Specialty Chemical, trade name "Irgacure907"), and 0.5 parts of a leveling agent (manufactured by DIC Corporation, trade name...

Embodiment 2

[0129] A light-diffusing element was produced in the same manner as in Example 1 except that the compounding quantity of the polymethyl methacrylate (PMMA) fine particles as light-diffusing fine particles was 20 parts. The obtained light-diffusion element was subjected to the evaluation of said (2)-(7). The results are shown in Table 1.

Embodiment 3

[0131] A light-diffusing element was produced in the same manner as in Example 1 except that the compounding quantity of the polymethyl methacrylate (PMMA) fine particles as light-diffusing fine particles was 30 parts. The obtained light-diffusion element was subjected to the evaluation of said (2)-(7). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com