Thin fiber and manufacture method thereof

A manufacturing method and optical fiber technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problem of uneven outer diameter of thin-diameter optical fiber, and achieve large core-cladding refractive index difference, good market prospect, and high refractive index big difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

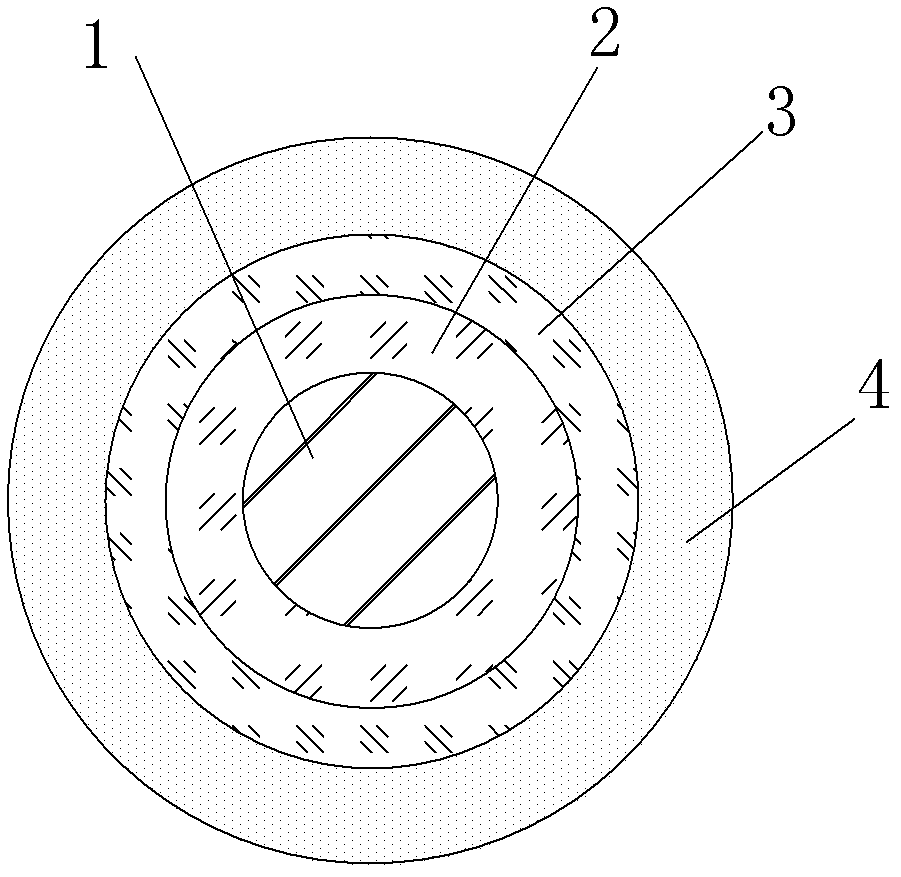

[0025] Such as figure 1 A kind of thin-diameter optical fiber shown, comprises diamond fiber core 2, and described diamond fiber core 2 contains reinforcing fiber 1, and the outer surface of described diamond fiber core 2 is provided with silica cladding 3, and described diamond fiber core 2 is provided with silica cladding 3, and described The outer surface of the silicon cladding 3 is provided with a coating layer 4, and the diamond core 2 is a solid or hollow fiber made of diamond.

[0026] Preferably, the reinforcing fibers 1 are metal fibers, metal alloy fibers or non-metal fibers. The reinforcing fibers 1 are quartz fibers.

[0027] A method for making a thin-diameter optical fiber, characterized in that it comprises the following steps:

[0028] Step 1, placing a section of fiber in a closed container;

[0029] Step 2, feed pure methane gas and hydrogen into the airtight container;

[0030] Step 3, then use a radio frequency or microwave device to heat the gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com