Silver pearlescent pigment, and preparation method and application thereof

A pearlescent pigment and pigment technology, applied in the field of pigments, can solve the problems of poor quality and brightness of multi-layer coating structure products, complicated processes, etc., and achieve the effects of stable and reliable product quality, simplified coating process, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Some embodiments of the present invention also provide a method for preparing the above-mentioned silver pearlescent pigment, which includes: sequentially coating the inner layer of titanium dioxide, the layer of silicon aggregated oxide and the outer layer of titanium dioxide on the surface of the pigment substrate by heating and hydrolyzing.

[0026] By means of heating and hydrolysis, in the process of coating the inner layer of titanium dioxide, the silicon aggregated oxide layer and the outer layer of titanium dioxide, the coating is only completed by controlling the temperature of the reaction system, which simplifies the process flow and does not require alkali neutralization (that is, no pH value control), which greatly saves the cost, and the whole reaction process is more controllable, which improves the stability of high-quality products.

[0027] Specifically, the heating hydrolysis method may include:

[0028] In an aqueous solution at a temperature of 80-1...

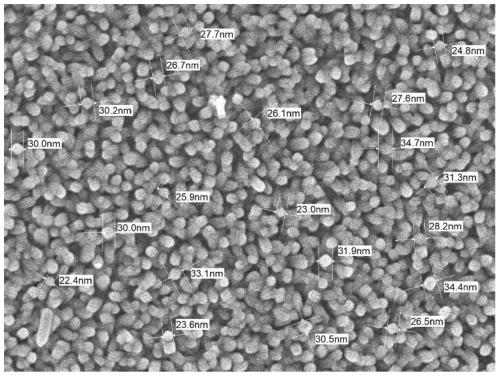

Embodiment 1

[0047] Weigh 100g of synthetic mica with a particle size of 5-45μm and a diameter-to-thickness ratio ≥ 60, put it in a 5L round bottom flask, add 2000mL of deionized water, put it in a water bath, stir at a rate of 300rps, and heat up to 70°C , add 100mL of 2.5% tin tetrachloride aqueous solution, finish adding in half an hour, then raise the temperature to 85°C, add dropwise 300mL titanium tetrachloride solution (the concentration of titanium tetrachloride is 2M / L) at a rate of 1mL / min, filter , to obtain filter cake. Then add 2000ml of ethanol, heat up to 40°, add 200ml of trichloropropyltriethoxysilane, finish the reaction after 24 hours, filter to obtain a filter cake. Add 2000mL of deionized water again, put it in a water bath, stir at a rate of 300rps, heat up to 70°C, add 100mL of 2.5% tin tetrachloride aqueous solution, add half an hour, then heat up to 85°C, with 1mL Add 300mL titanium tetrachloride solution (titanium tetrachloride concentration is 2M / L) dropwise at ...

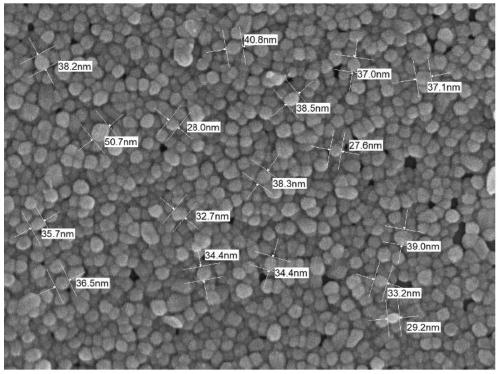

Embodiment 2

[0049] Weigh 100g of synthetic mica with a particle size of 5-45μm and a diameter-to-thickness ratio ≥ 60, put it in a 5L round bottom flask, add 2000mL of deionized water, put it in a water bath, stir at a rate of 300rps, and heat up to 70°C , add 100mL of 2.5% tin tetrachloride aqueous solution, finish adding in half an hour, then raise the temperature to 85°C, add dropwise 300mL titanium tetrachloride solution (the concentration of titanium tetrachloride is 2M / L) at a rate of 1mL / min, filter , to obtain filter cake. Then add 2000ml of ethanol, heat up to 60°, add 200ml of trichloropropyltriethoxysilane, finish the reaction after 24 hours, filter to obtain a filter cake. Add 2000mL of deionized water again, put it in a water bath, stir at 300rps, heat up to 70°C, add 100mL of 2.5% tin tetrachloride aqueous solution, add half an hour, then heat up to 90°C, add 1mL Add 300mL titanium tetrachloride solution (titanium tetrachloride concentration is 2M / L) dropwise at a rate of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com