Fine dried noodle making machine

A noodle machine and dough technology, applied in the directions of dough sheeter/roller/rolling pin, dough forming and slitting combination, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below by specific embodiments:

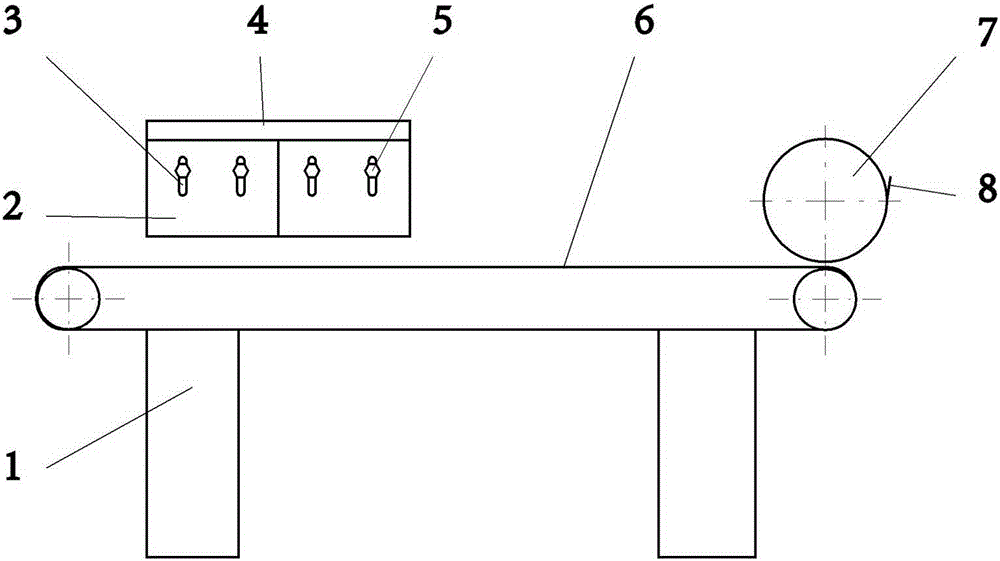

[0012] Reference numerals in the accompanying drawings include: support frame 1 , blade 2 , through groove 3 , pressing plate 4 , positioning bolt 5 , conveyor belt 6 , pressing roller 7 , and stripper 8 .

[0013] The embodiment is basically as attached figure 1 Shown:

[0014] A noodle machine of the present invention includes a dough flattening mechanism, the dough flattening mechanism includes a support frame 1, a conveyor belt 6 is installed on the support frame 1, and a hydraulically driven rectangular platen 4 is installed directly above the feeding position of the conveyor belt 6 , the surface of the pressing plate 4 is parallel to the surface of the conveyor belt 6, and its transverse width is consistent with the width of the conveyor belt 6 to ensure that there is enough pressing surface to contact the dough, so that the surface of the dough after pressing is flat, in additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com