An automatic skin pressing and skin picking device for dumplings

An automatic, dumpling technology, applied in the direction of dough extruder, etc., can solve the problems of high machine damage rate, rough product skin, low production efficiency, etc., and achieve smooth operation of the machine, better taste and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

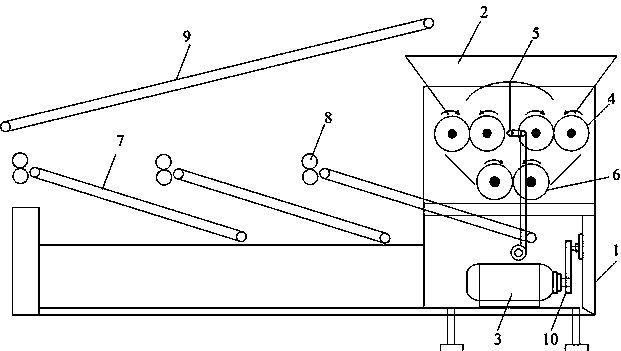

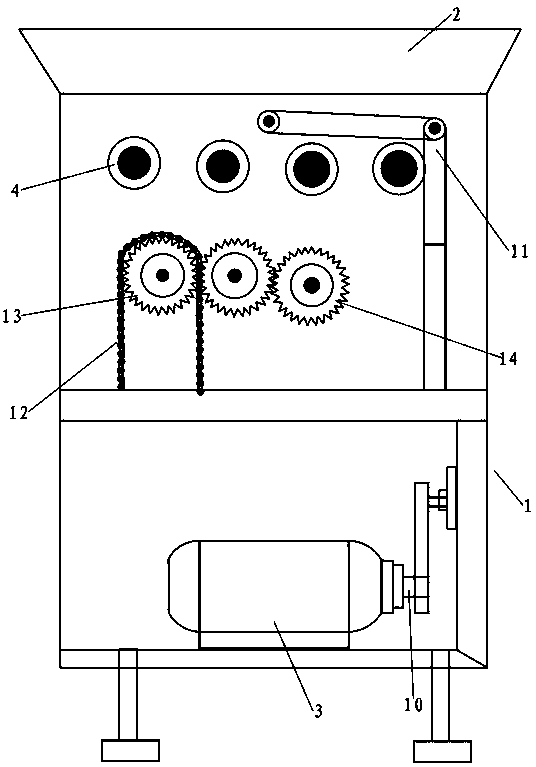

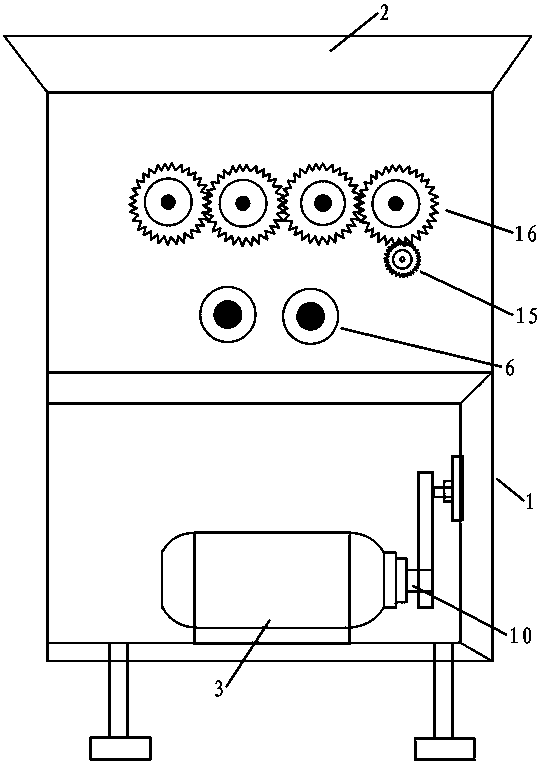

[0023] Such as Figure 1-Figure 5 As shown, a dumpling automatic skin pressing and skinning device includes a frame 1, a geared motor 3 fixed on the frame, a hopper 2 arranged above the frame, two pairs of patterned rollers 4 that rotate in opposite directions, and a skinning device. device. The end surface of the pattern roller 4 is provided with a gear 16, and the gears 16 on the end surfaces of two pairs of pattern rollers mesh with each other. A pair of compound rollers 6 are arranged below the two pairs of pattern rollers 4 , gears 14 are arranged on the end faces of the compound rollers 6 , and the gears 14 on the end faces of the compound rollers mesh with each other. The top of two pairs of pattern rollers 4 is swung to set pounding face arm 5, and pounding face arm 5 is arranged on the inside of hopper 2 for the arm with arc, and the arc surface of pounding face arm 5 is towards two pairs of pattern rollers 4 directions, The midpoint of the arc surface is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com