Defoaming method for thickener in beneficiation plant and device implementing same

A technology of thickeners and concentrators, which is applied to the device of the defoaming method and the field of eliminating floating foam in the thickener, which can solve the problems of failure and impact of foaming agents, achieve effective defoaming effect, low energy consumption, and reduce fineness The effect of mine loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

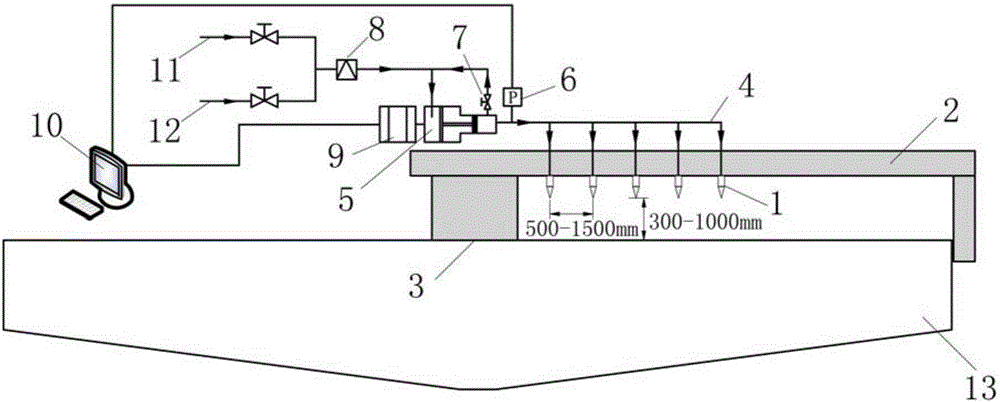

[0036] The foam defoaming test of a 38m thickener in Henan Luanchuan Tungsten Ore Concentrator was carried out by adopting the method described in the present invention. Before the test, the thickness of the foam layer of the concentrator thickener was about 500mm, the solid content of the surface foam was about 60%, the solid content of the overflow water was about 7%, and the loss of tungsten in the overflow water was about 5%. During the test, according to figure 1As shown, nine high-pressure atomizing nozzles 1 are sequentially arranged on the thickener arm 2 of the thickener 13 along the 3 ends of the central rotating shaft, and the distance between adjacent high-pressure atomizing nozzles 1 is 1000mm. Change and adjust up and down, the distance is always kept at 500mm, and the water outlet form of the high-pressure atomizing nozzle 1 is adjusted to be cone-shaped mist, and the cone angle is 15°. The speed of the variable frequency motor 9 is adjusted by the frequency co...

Embodiment 2

[0038] The defoaming test of two 20m thickeners in Hunan Chenzhou fluorite ore dressing plant was carried out by using the method described in the present invention. Before the test, the thickness of the foam layer of the concentrator thickener was about 300mm, the solid content of the surface foam was about 57%, the solid content of the overflow water was about 6%, and the loss of fluorite in the overflow water was about 6%. During the test, according to figure 1 As shown, on the thickener arm 2 of the thickener 13, five high-pressure atomizing nozzles 1 are sequentially arranged along the 3 ends of the central rotating shaft, and the distance between adjacent high-pressure atomizing nozzles 1 is 1000mm. Change and adjust up and down, the distance is always kept at 500mm, and the water outlet form of the high-pressure atomizing nozzle 1 is adjusted to be cone-shaped mist, and the cone angle is 15°. The speed of the variable frequency motor 9 is adjusted by the frequency conv...

Embodiment 3

[0040] The defoaming test of a 32m thickener in Hunan Shizhuyuan polymetallic mineral processing plant was carried out by adopting the method of the present invention. Before the test, the thickness of the foam layer of the concentrator thickener was about 300mm, the solid content of the surface foam was about 61%, the solid content of the overflow water was about 8%, the loss of tungsten in the overflow water was about 6%, and the tin was about 11%. During the test, according to figure 1 As shown, eight high-pressure atomizing nozzles 1 are sequentially arranged on the thickener arm 2 of the thickener 13 along the 3 ends of the central rotating shaft, and the distance between adjacent high-pressure atomizing nozzles 1 is 1000mm. Change and adjust up and down, the distance is always kept at 500mm, and the water outlet form of the high-pressure atomizing nozzle 1 is adjusted to be cone-shaped mist, and the cone angle is 15°. The speed of the variable frequency motor 9 is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com