Organic silicone defoaming agent for PVC and preparation method thereof

A silicone defoamer and defoamer technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of demulsification and stratification, poor stability, etc., achieve good compatibility, improve High temperature stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

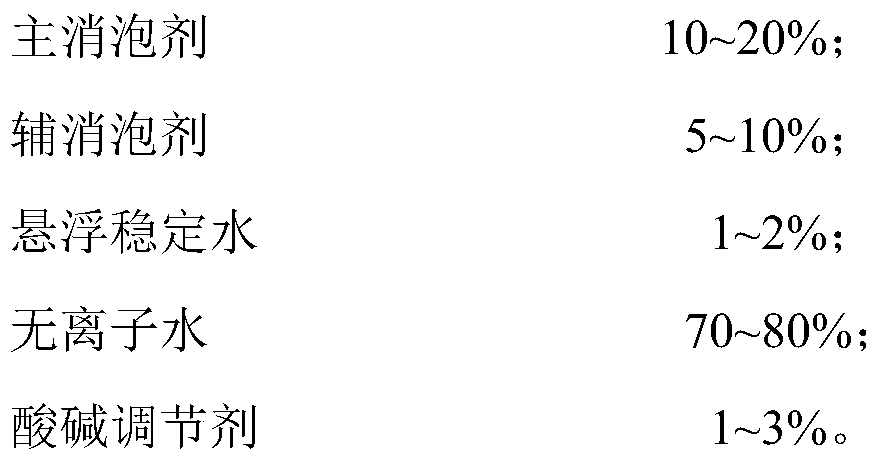

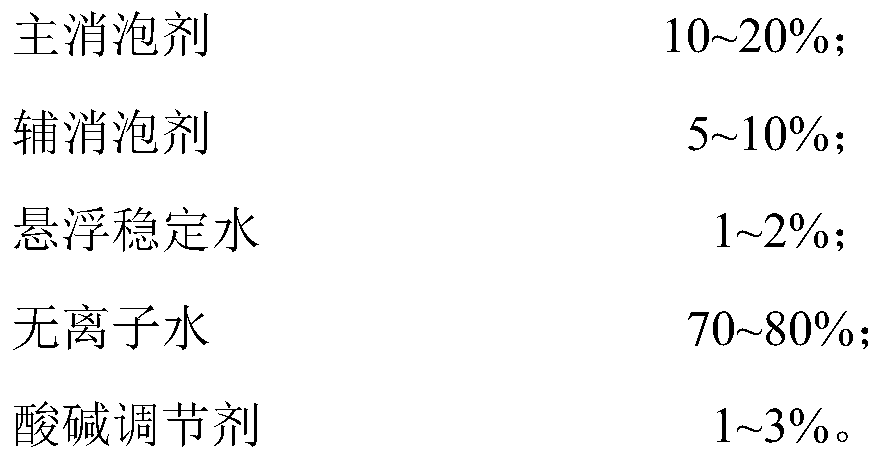

[0034] The preparation method of a silicone defoamer for PVC in this embodiment comprises the following steps: adding 1% polyacrylic acid mother liquor into 75% deionized water, stirring for 20 minutes, and then adding 1% acid-base adjustment Slowly adjust the pH of the stable water to 6. When the pH of the stable water is stable, the solution is transparent. Stir for 10 minutes. Add 15% of the main defoamer polyether silicone oil and 8% of the auxiliary defoamer. Water-soluble ether, stirred for 30 minutes, then sheared for 10 minutes.

[0035] Sample performance test:

[0036] 1. Thermal stability:

[0037] After the sample was placed in an oven at a temperature of 100 degrees for 1 hour, it was observed that there was no layered precipitation in the sample aqueous solution.

[0038] 2. Normal temperature stability test

[0039] Place the sample at room temperature for 3 months, the sample has no delamination phenomenon, and the state is good and the fluidity is good.

...

Embodiment 2

[0043] The preparation method of a silicone defoamer for PVC in this embodiment comprises the following steps: adding 1.5% polyacrylic acid mother liquor into 75% deionized water, stirring for 20 minutes, adding 1.5% acid-base regulator hydrogen Sodium oxide solution, adjust the pH of the stable water to be 6, when the pH of the stable water is stable, the solution is transparent, add 13% of the main defoamer modified silicon (polyether silicone oil), 9% of the auxiliary defoamer water-soluble ether , stirred for 30 minutes, then sheared for 10 minutes. The stability and the defoaming and anti-foaming effect of the defoamer obtained in this embodiment are closer to those in Example 1.

Embodiment 3

[0045] A preparation method of a silicone defoamer for PVC in this embodiment comprises the following steps: adding 2% polyacrylic acid mother liquor into 79% deionized water, stirring for 15 minutes, adding 2% hydrogen as an acid-base regulator Sodium oxide solution, adjust the pH of the stable water to be 7, when the pH of the stable water is stable, the solution is transparent, add 10% of the main defoamer modified silicon (polyether silicone oil), 7% of the auxiliary defoamer water-soluble ether , stirred for 25 minutes, then sheared for 5 minutes. The stability and the defoaming and anti-foaming effect of the defoamer obtained in this embodiment are closer to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com