Spiral-flow type defoaming device

A defoaming device and swirling technology, which are applied in the field of defoaming of water bodies, can solve the problems of corroding metal structures, vegetation, foam overflow, polluting the factory area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

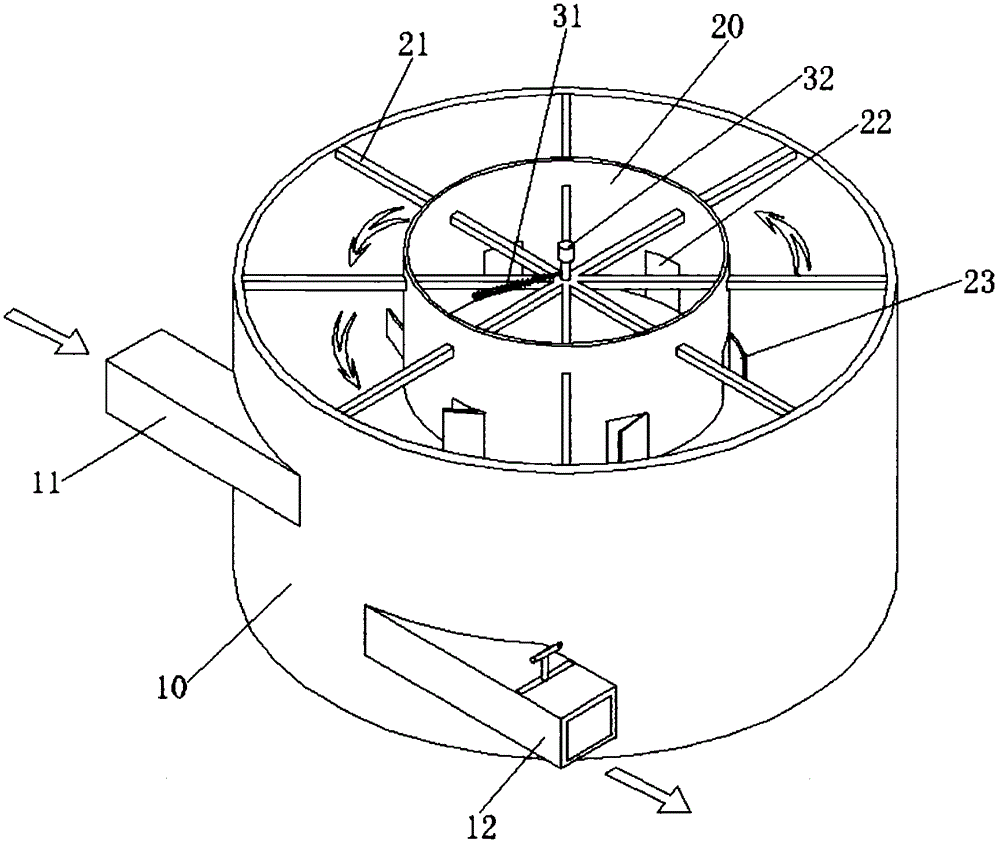

[0017] Such as figure 1 As shown, the swirl defoaming device is mainly composed of a swirl defoamer 10, a foam collector 20 and a brush defoamer, the swirl defoamer 10 is a drum structure, the swirl defoamer The flow defoaming body is provided with a tangential direction diversion into the inflow port 10 in the swirl diversion defoaming body, and the inflow port 10 of the tangential direction diversion and the barrel wall of the swirl diversion defoamer make the incoming foamy water generate a swirl Flow force, the centrifugal force generated by the swirl makes the foam gather towards the center of the swirl defoamer. The outer wall of the swirl diversion defoaming body is also provided with a water outlet 12, the water outlet 12 is arranged along the tangential direction of the swirl diversion defoamer outer wall, and the horizontal position of the water outlet 12 is lower than that of the flow. The inlet 11 and the water outlet 12 allow the water after centrifugation to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com