Industrial dust remover

An industrial dust collector and base plate technology, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems affecting the efficiency of equipment dust removal, increase the labor intensity of users, shorten the service life of equipment, etc., and achieve effective filtration Dust removal, maintaining purification and dust removal effect, good effect of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

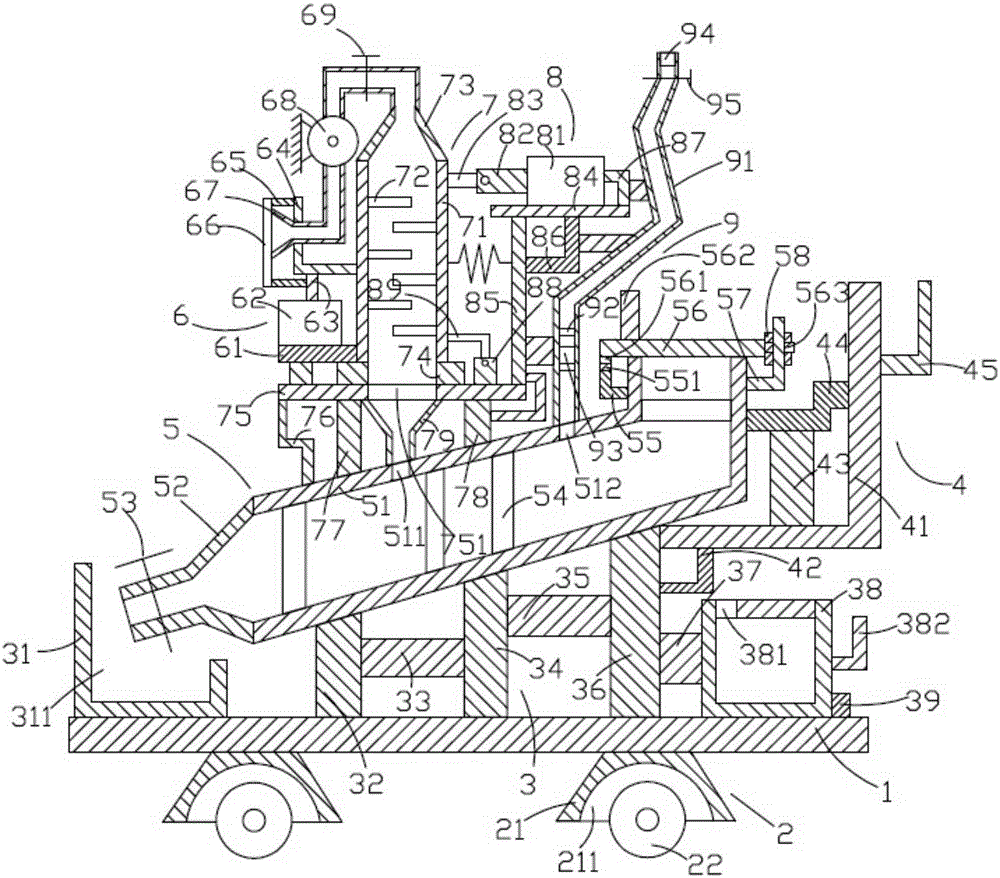

[0020] like figure 1 As shown, the industrial dust collector of the present invention includes a base plate 1, a roller device 2 located below the base plate 1, a support device 3 located above the base plate 1, a gripping device 4 located above the support device 3, and a The humidification device 5 above the support device 3, the filter device 7 above the humidifier 5, the air intake device 6 on the left side of the filter device 7, the shaking device 8 on the right side of the filter device 7 and The air outlet device 9 on the right side of the rocking device 8 .

[0021] like figure 1 As shown, the base plate 1 is in the shape of a cuboid, and the base plate 1 is placed horizontally.

[0022] like figure 1 As shown, there are two roller devices 2 located on the left and right sides respectively. The roller device 2 includes a first support block 21 and a roller 22 located below the first support block 21 . The cross-section of the first support block 21 is an isosceles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com