Flue gas denitration device for carbon pot calciner and denitration technology of flue gas denitration device

A tank-type calciner and calciner technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effect of ensuring safe and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

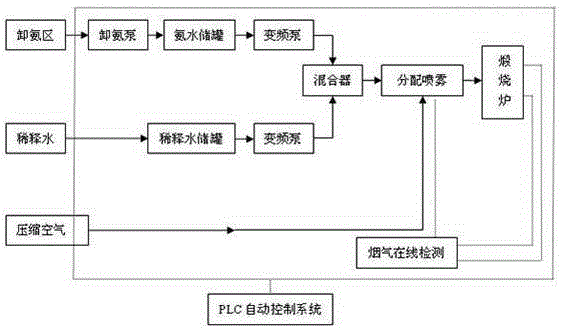

[0014] As shown in the figure, a carbon tank type calciner flue gas denitration device is mainly composed of ammonia water storage system, ammonia water delivery system, ammonia water dilution system, reducing agent injection system in front of the furnace, calciner, PLC control system and flue gas online detection system The ammonia water storage system includes the ammonia discharge pump and the ammonia water storage tank, the ammonia water delivery system includes two frequency conversion pumps, the ammonia water dilution system includes the dilution water storage tank, the frequency conversion pump and the mixer, and the reductant furnace front injection system consists of a distribution spray mechanism and cooling The air supply mechanism consists of several spray guns, and the spray guns are arranged on the flue at the outlet of the calciner. The cooling air supply mechanism includes a compressed air generator, and the air duct of the compressed air generator communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com