Fume temperature coordination type wide load denitrification system

A technology for flue gas temperature and denitrification, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as catalyst poisoning and failure, and achieve the effects of easy structure, sufficient load width, and remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

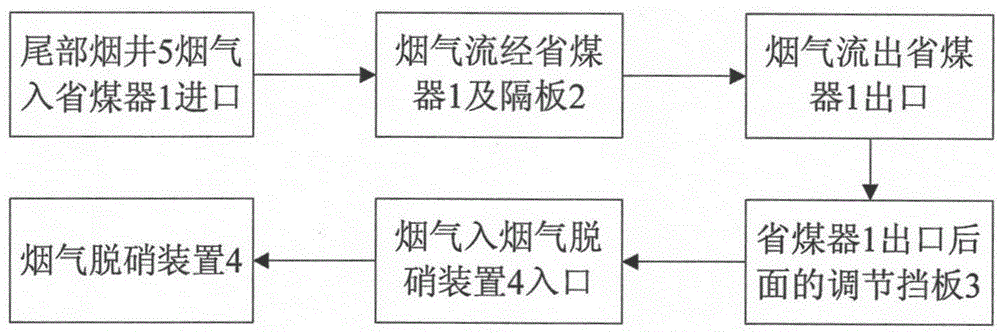

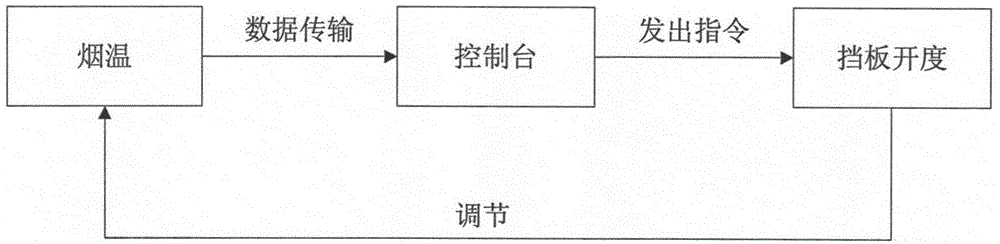

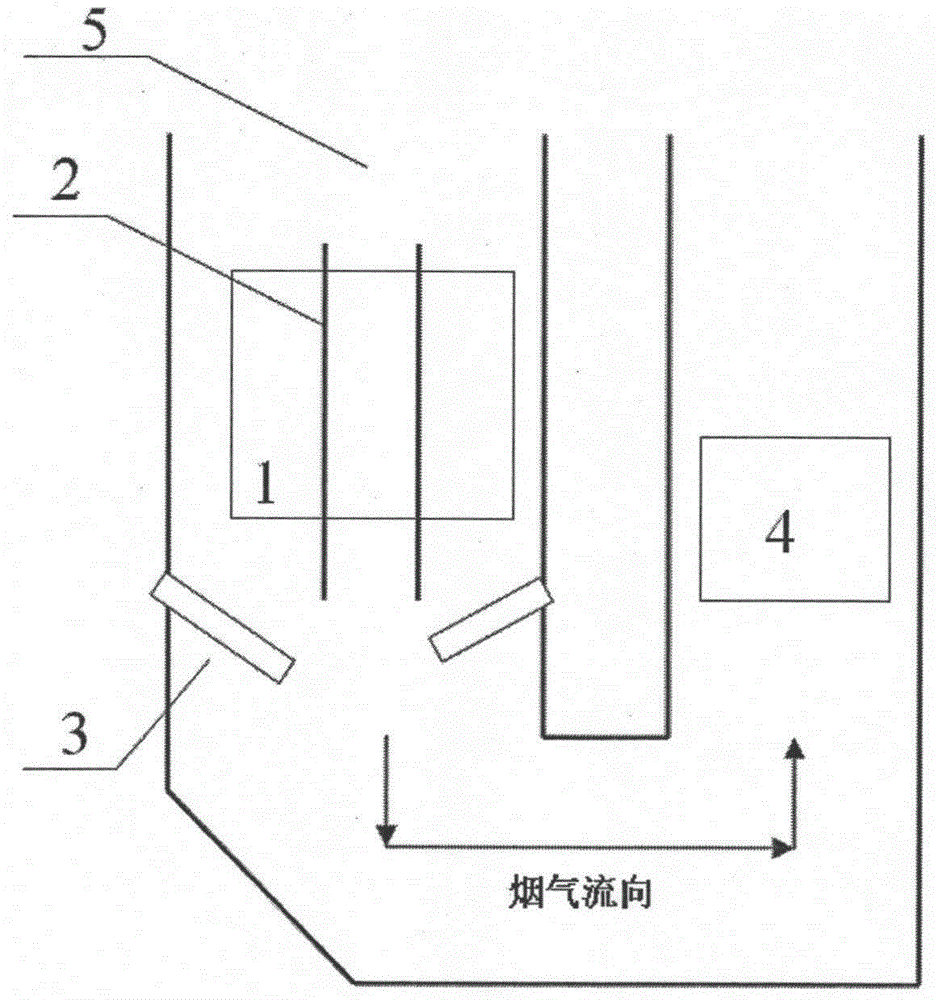

[0021] The present invention is a wide-load denitrification system with coordinated flue gas temperature, which is mainly used for raising and adjusting the flue gas temperature before the flue gas denitrification device 4 at the boiler tail, such as figure 1 As shown, it includes the tail smoke shaft 5, the economizer 1 arranged in the front section of the tail smoke shaft 5, the partition plate 2 in the middle of the economizer 1, and the flue gas denitrification device 4 in the rear section of the tail smoke shaft 5. The back of the flue gas outlet of the economizer 1 in the tail flue shaft 5 is installed with an adjusting baffle 3 controlled by the control system to open and close. The fixed end of the adjusting baffle 3 is fixed on the side wall of the smoke well 5 at the tail. The movable end of the adjustment baffle 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com