A method for preparing sun-cured red tobacco extract and its application

A technology of extracting and sun-dried red tobacco, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of impact, bad taste of reconstituted tobacco leaves, high irritation, etc., and achieve easy operation of process conditions, large industrial application prospects, and process The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

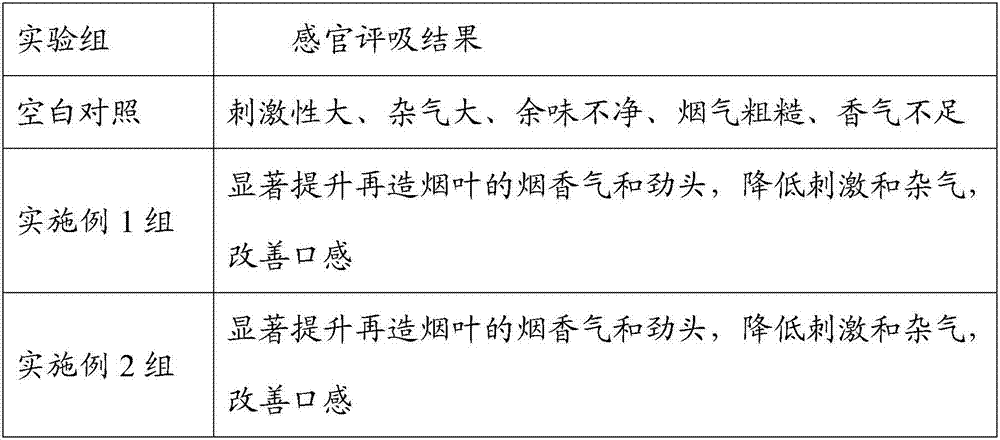

Examples

Embodiment 1

[0022] The invention provides a preparation method of sun-cured red tobacco extract, comprising the following steps:

[0023] (1) Two-step enzymatic aroma enhancement and biotransformation of sun-cured tobacco leaves: the first step is to enzymatically produce aroma, mix sun-cured tobacco leaves and water at a mass ratio of 1:10, and adjust the pH to 4.5 with citric acid. At 45°C, add 0.05% of the mass of tobacco leaves β-glucosidase (enzyme activity 100u / g, food grade), stir evenly, and incubate for 2 hours; in the second step of biotransformation, add the mass of tobacco leaves to the fermentation broth 0.01% protease and cellulase (enzyme activity is 100,000 u / g, mass ratio 1:1, food grade), stir evenly, incubate at 45°C for 2 hours, and inactivate the enzyme at 100°C for 3 minutes;

[0024] (2) Maillard reaction and reflux extraction of sun-cured red tobacco leaves: extract the two-step fermentation liquid in step (1) at 50°C for 2 hours under reflux, filter with suction, ...

Embodiment 2

[0031] The invention provides a preparation method of sun-cured red tobacco extract, comprising the following steps:

[0032] (1) Two-step enzymatic aroma enhancement and biotransformation of sun-cured tobacco leaves: the first step is to enzymatically produce aroma, mix sun-cured tobacco leaves and water at a mass ratio of 1:15, and adjust the pH to 5.0 with citric acid. At 50°C, add 0.1% β-glucosidase (enzyme activity 100u / g, food grade) of the mass of tobacco leaves, stir evenly, and incubate for 2.5 hours; in the second step of biotransformation, add 0.05% β-glucosidase to the above fermentation broth protease and cellulase (enzyme activity is 50,000 u / g, mass ratio 1:1, food grade), stir evenly, incubate at 50°C for 2.5 hours, and inactivate the enzyme at 100°C for 5 minutes;

[0033] (2) Maillard reaction and reflux extraction of sun-cured red tobacco leaves: extract the two-step fermentation liquid in step (1) at 55°C for 3.5 hours under reflux, filter with suction, ret...

Embodiment 3

[0040] The invention provides a preparation method of sun-cured red tobacco extract, comprising the following steps:

[0041] (1) Two-step enzymatic aroma enhancement and biotransformation of sun-cured tobacco leaves: the first step is to enzymatically produce aroma, mix sun-cured tobacco leaves and water at a mass ratio of 1:35, and adjust the pH to 5.5 with citric acid. At 55°C, add 0.25% β-glucosidase (enzyme activity 100u / g, food grade) of the mass of tobacco leaves, stir evenly, and incubate for 4 hours; in the second step of biotransformation, add 0.1% β-glucosidase to the above fermentation broth Protease and cellulase (enzyme activity is 20,000 u / g, mass ratio 1:1, food grade), stir evenly, incubate at 60°C for 4 hours, and inactivate the enzyme at 100°C for 4 minutes;

[0042] (2) Maillard reaction and reflux extraction of sun-cured red tobacco leaves: the two-step fermentation liquid in step (1) was extracted at 60°C for 5 hours under reflux, suction filtered, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com