Cutting device for copper belt

A copper strip and cutting technology, applied in the mechanical field, can solve the problems that the prepreg cannot be adjusted in tension, the tension control accuracy of the tension spring is not high, and the size of the copper strip is different, and achieves simple structure, excellent automation performance, and excellent practical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

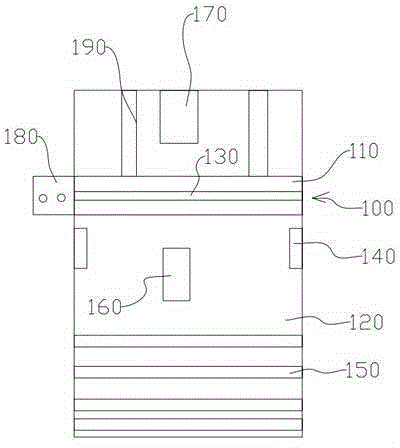

[0014] See figure 1 , One A copper strip cutting device includes a machine base 100, the upper end of the machine base 100 is provided with a cutter head 110 driven by a motor, the lower end of the machine base 100 is provided with a flat work surface 120, and the cutter head 110 is installed with a cutter 130, the two ends of the work surface 120 are provided with photoelectric protection devices 140, the front of the work surface 120 is provided with a roller table 150 that facilitates the movement of the material, and the front of the cutter head 110 is provided with a leveling cavity 160 for flattening the bent part of the copper strip A block 170 is provided behind the cutter head 110, and a control panel 180 is installed on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com