A rear cover outer plate assembly welding mechanism

A welding mechanism and assembly technology, applied in welding equipment, resistance welding equipment, electrode characteristics, etc., can solve problems such as inability to weld and reduce work intensity, and achieve the effect of reducing work intensity, occupying a small space, and breaking through limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

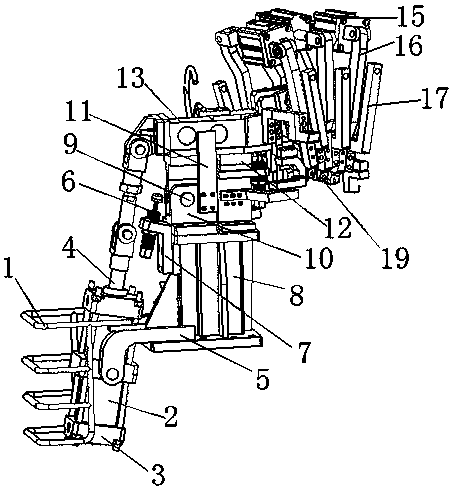

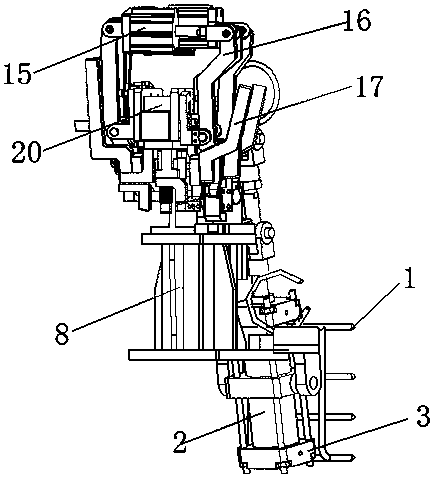

[0029] combine figure 1 with figure 2 , a rear cover outer panel assembly welding mechanism in this embodiment includes a swing arm mechanism, a puppet welding mechanism, a support body 8 and a swing arm base 20, wherein both the swing arm mechanism and the puppet welding mechanism are fixedly connected to the swing arm on the base 20.

[0030] Such as figure 1 As shown, the swing arm mechanism includes a protective cover 1, a first cylinder 2, a cylinder seat 3, a piston rod 4, a connecting block 5, a turning point 9, a connecting plate 10, a rough guide 11, a fine stopper 12 and a pressing arm 13, The outer side of the first cylinder 2 is provided with a protective cover 1, and the first cylinder 2 is obliquely arranged on the cylinder block 3, and the middle position of the first cylinder 2 is connected with one end of the connection block 5, and the other end of the connection block 5 is fixed Connected to the end surface of the lower part of the support body 8, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com