Vitreous binder, standard hardness block and manufacturing method thereof

A technology of standard hardness block and manufacturing method, which is applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of unstable composition, unstable bonding performance of bonding agent, large difference in hardness value of standard grinding wheel hardness blocks, etc., and achieve stability binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Vitreous binder

[0033] The vitreous bond in this embodiment is composed of the following components by mass: 87.5 parts of glass powder, 7.5 parts of borax, and 5 parts of zinc oxide. Put the above components into the mixer and mix well to form the glassy binder.

[0034] 2. Standard hardness block

[0035] The standard hardness block using the vitreous bond of this embodiment is composed of the following components in mass percentage: 40% vitreous bond and 60% abrasive. The abrasive is hollow spherical corundum with a particle size of F36.

[0036] 3. Manufacturing method of standard hardness block

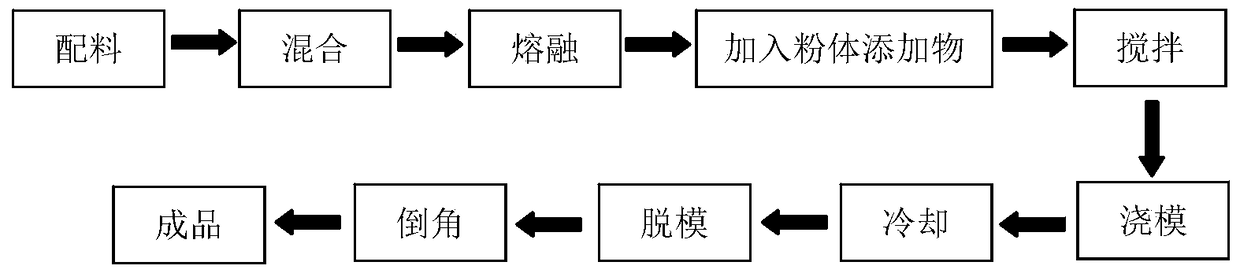

[0037] The manufacturing method of the standard hardness block of this embodiment, the manufacturing process is as follows figure 1 As shown, it is manufactured by the following steps:

[0038] 1) When the vitreous binder is heated to 800°C, it will completely melt into a liquid;

[0039] 2) Add hollow spherical corundum to the above liquid, stir for 5 minutes u...

Embodiment 2

[0043] 1. Vitreous binder

[0044] The vitreous bond in this embodiment is composed of the following components by mass: 17 parts of glass powder, 1 part of borax, and 2 parts of zinc oxide. The preparation method is the same as in Example 1.

[0045] 2. Standard hardness block

[0046] The standard hardness block using the vitreous bond of this embodiment is composed of the following components in mass percentage: 20% vitreous bond and 80% abrasive. The abrasive is hollow spherical corundum with a particle size of F30.

[0047] 3. Manufacturing method of standard hardness block

[0048] The manufacturing method of the standard hardness block of this embodiment is manufactured by the following steps:

[0049] 1) When the vitreous binder is heated to 1000°C, it will completely melt into a liquid;

[0050] 2) Add hollow spherical corundum to the above liquid, stir for 10 minutes until completely dispersed and evenly, and obtain a mixed liquid;

[0051] 3) adding the mixed ...

Embodiment 3

[0054] 1. Vitreous binder

[0055] The vitreous bond in this embodiment is composed of the following components by mass: 88 parts of glass powder, 8 parts of borax, and 4 parts of zinc oxide. The preparation method is the same as in Example 1.

[0056] 2. Standard hardness block

[0057] The standard hardness block using the vitreous bond of this embodiment is composed of the following components in mass percentage: 25% vitreous bond and 75% abrasive. The abrasive is hollow spherical corundum with a particle size of F10.

[0058] 3. Manufacturing method of standard hardness block

[0059] The manufacturing method of the standard hardness block of this embodiment is manufactured by the following steps:

[0060] 1) When the vitreous binder is heated to 900°C, it will completely melt into a liquid;

[0061] 2) Add hollow spherical corundum to the above liquid, stir for 12 minutes until completely dispersed and uniform, and obtain a mixed liquid;

[0062] 3) adding the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com