A fully automatic die-cutting machine gripper

A die-cutting machine and gripper technology, which is applied in object supply, metal processing, pile separation, etc., can solve the problems of poor consistency of action and complex structure, and achieve the effect of fewer parts, easy disassembly and replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments:

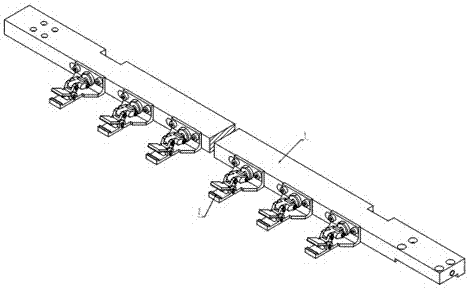

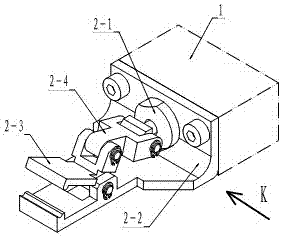

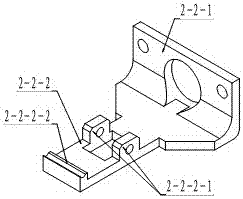

[0022] See figure 1 , figure 2 , The gripper of the automatic die-cutting machine of the present invention includes a set of gripper units 2, in which each gripper unit 2 is provided with a cylinder 2-1, fixed teeth 2-2, and movable teeth 2-3 and connecting rod 2-4; the fixed tooth piece 2-2 is installed on the die cutting machine tooth row 1, and is hinged and assembled with the movable tooth piece 2-3; the movable tooth piece 2-3 is also connected to the connecting rod 2-4 is hinged and assembled at one end; the other end of the connecting rod 2-4 is hinged and assembled with the piston rod of the cylinder 2-1; an external thread is provided on the outer wall of the cylinder 2-1, and the die cutting machine tooth row 1 is provided with A threaded hole matched with the outer wall of the cylinder 2-1, the cylinder 2-1 is fixed on the die cutting machine tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com