Olefin polymerization catalyst

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalysts, can solve the problems of low activity and low catalyst orientation ability, and achieve the effects of high catalytic activity, wide molecular weight distribution range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of olefin polymerization catalyst of the present invention, wherein general formula is the amount of the internal electron donor compound of I and MgCl 2 The molar ratio is 0.01, Ti(OR 1 ) The content of nXy is 5wt%, and the general formula is AlR 2 n x 3-n The content of organoaluminum compounds is MgCl 2 10 times.

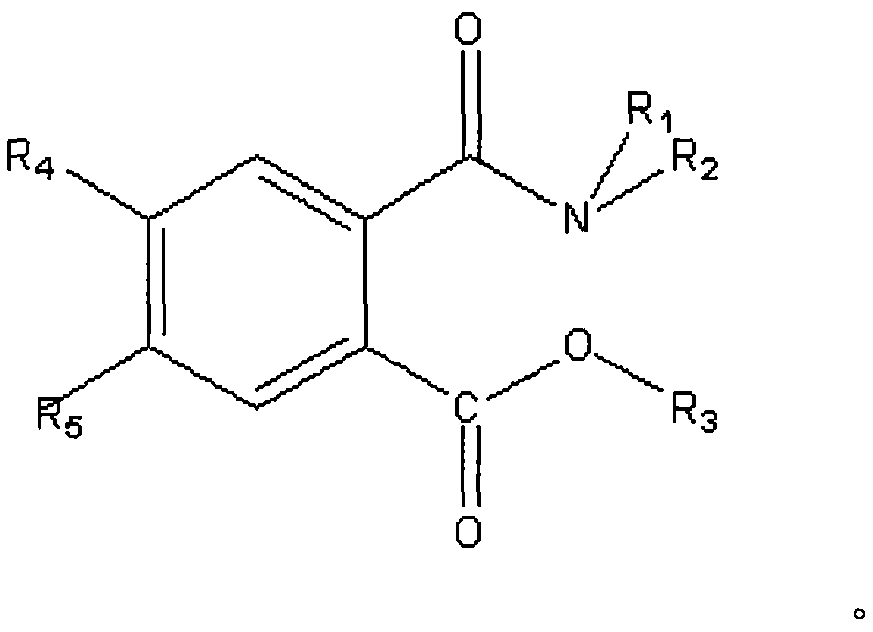

[0017] Preferably, the structure of the internal electron-donating compound is:

[0018]

[0019] Preferably, the structure of the organoaluminum compound can be one or more of trimethylaluminum, triethylaluminum, tripropylaluminum, monochlorodiethylaluminum, dichloroethylaluminum or triisobutylaluminum .

[0020] Preferably, the silane-type external electron-donating compound may be one or more of tetramethoxysilane, tetraethoxysilane, methyltrimethoxysilylmethyltriethoxysilane.

[0021] Preferably, Ti(OR 1 )nXy is TiCl 4 .

Embodiment 2

[0023] A kind of olefin polymerization catalyst of the present invention, wherein general formula is the amount of the internal electron donor compound of I and MgCl 2 The molar ratio is 0.05, Ti(OR 1 ) The content of nXy is 10wt%, and the general formula is AlR 2 n x 3-n The content of organoaluminum compounds is MgCl 2 50 times.

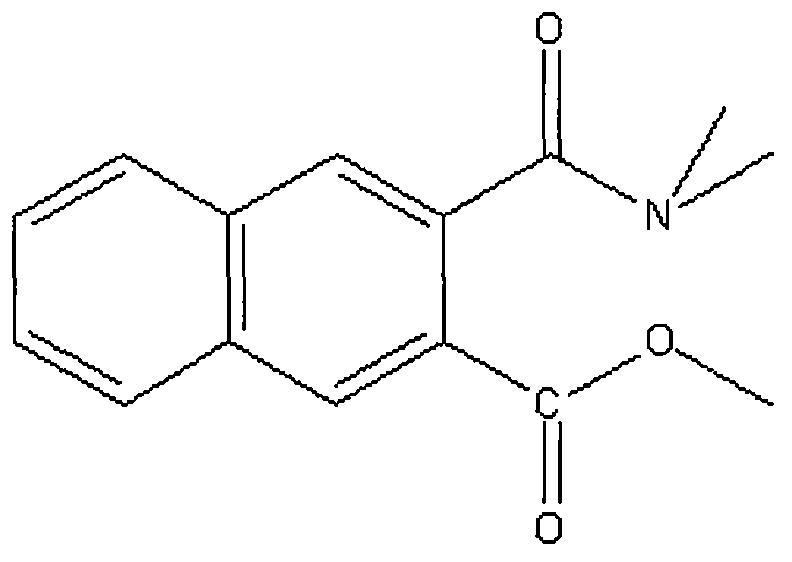

[0024] Preferably, the structure of the internal electron-donating compound is:

[0025]

[0026] Preferably, the structure of the organoaluminum compound can be one or more of trimethylaluminum, triethylaluminum, tripropylaluminum, monochlorodiethylaluminum, dichloroethylaluminum or triisobutylaluminum .

[0027] Preferably, the silane-type external electron-donating compound may be one or more of tetramethoxysilane, tetraethoxysilane, methyltrimethoxysilylmethyltriethoxysilane.

[0028] Preferably, Ti(OR 1 )nXy is TiCl 4 .

Embodiment 3

[0030] A kind of olefin polymerization catalyst of the present invention, wherein general formula is the amount of the internal electron donor compound of I and MgCl 2 The molar ratio is 0.05, Ti(OR 1 ) The content of nXy is 10wt%, and the general formula is AlR 2 n x 3-n The content of organoaluminum compounds is MgCl 2 50 times.

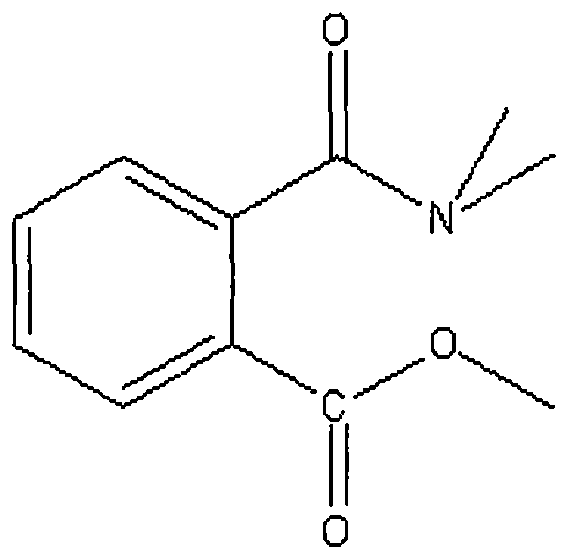

[0031] Preferably, the structure of the internal electron-donating compound is:

[0032]

[0033] Preferably, the structure of the organoaluminum compound can be one or more of trimethylaluminum, triethylaluminum, tripropylaluminum, monochlorodiethylaluminum, dichloroethylaluminum or triisobutylaluminum .

[0034] Preferably, the silane-type external electron-donating compound may be one or more of tetramethoxysilane, tetraethoxysilane, methyltrimethoxysilylmethyltriethoxysilane.

[0035] Preferably, Ti(OR 1 )nXy is TiCl 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com