Corrosion-resistant structure of assembled building exterior wall dry hanging node and construction method of corrosion-resistant structure

A kind of building exterior wall, prefabricated technology, applied in the direction of building components, building structure, building materials processing, etc., can solve problems such as anti-corrosion problems, to avoid oxidation and rust, improve assembly efficiency, and eliminate potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

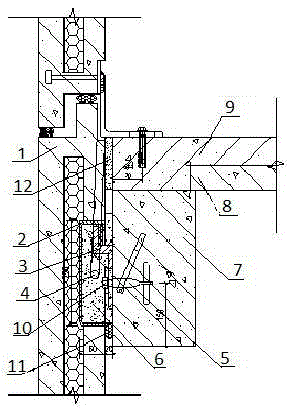

[0029] join figure 1 , the anti-corrosion structure of the dry-hanging node of the exterior wall of the prefabricated building of the present invention, the dry-hanging node of the outer wall includes a pre-embedded box embedded in the prefabricated dry-hanging outer wall panel and a hook seat fixedly connected with the main body of the building, the The upper part of the hook seat passes through the side opening of the pre-embedded box and enters the upper part of the inner cavity of the pre-embedded box to support the entire prefabricated dry-hanging exterior wall panel; Embed the grouting pipe in the inner cavity of the box, and at the same time, in the construction gap between the prefabricated dry-hanging outer wall panel and the main body of the building, there are U-shaped foam rods surrounding the dry-hanging nodes of the outer wall. Filling cement slurry is injected into the construction gaps surrounding the rods to wrap the entire dry-hanging node.

[0030] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com