Air-cooling structure of internal combustion engine of motorcycle

An air-cooled structure, internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of easy ablation of the seat ring, uneven deformation, out-of-round cylinder block, etc., to improve the overall stability, avoid overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

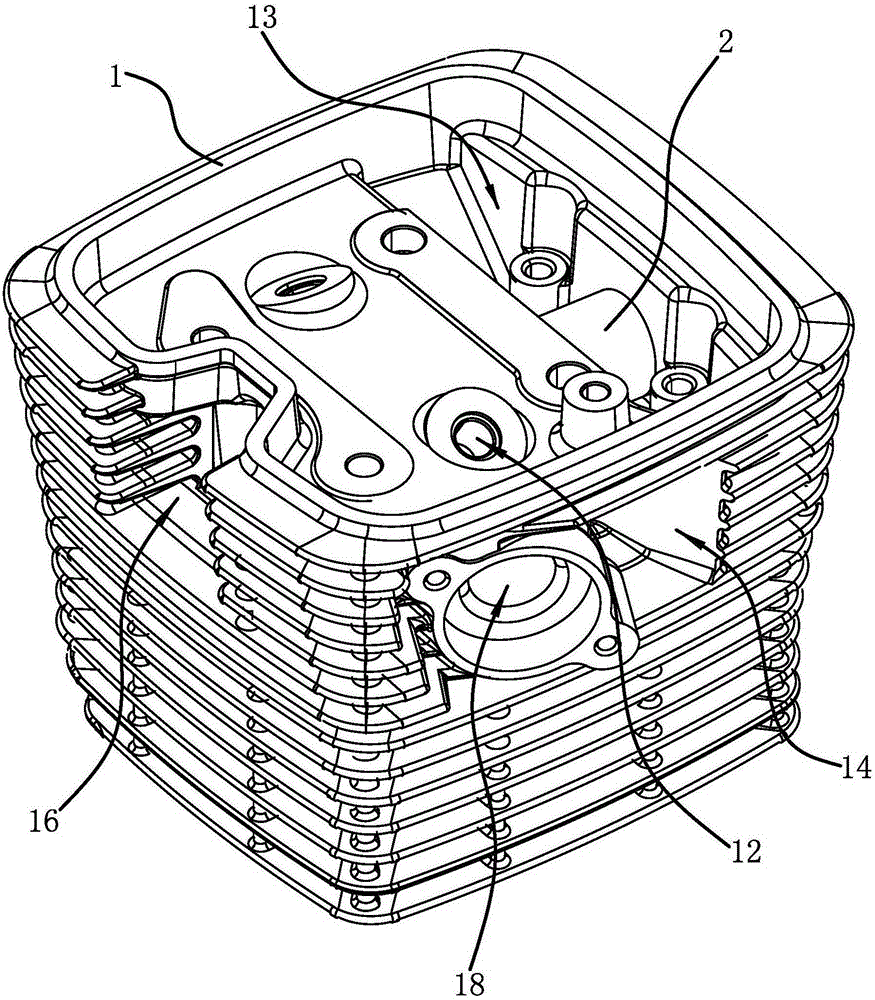

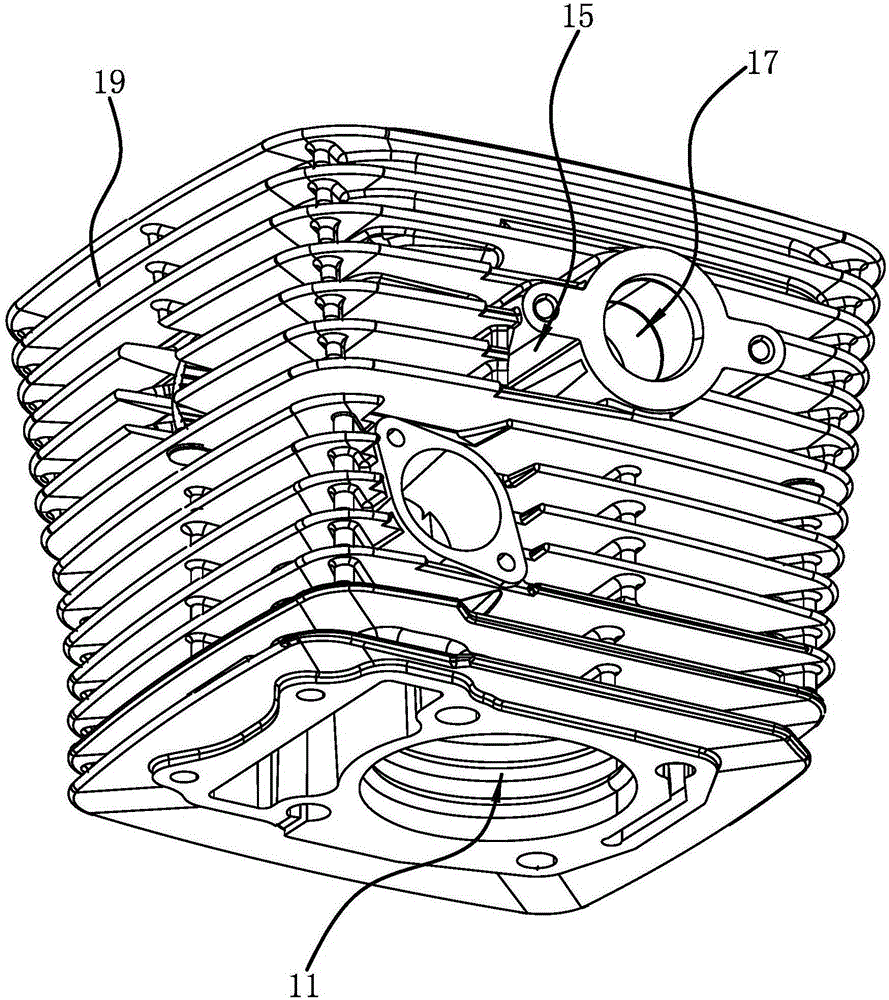

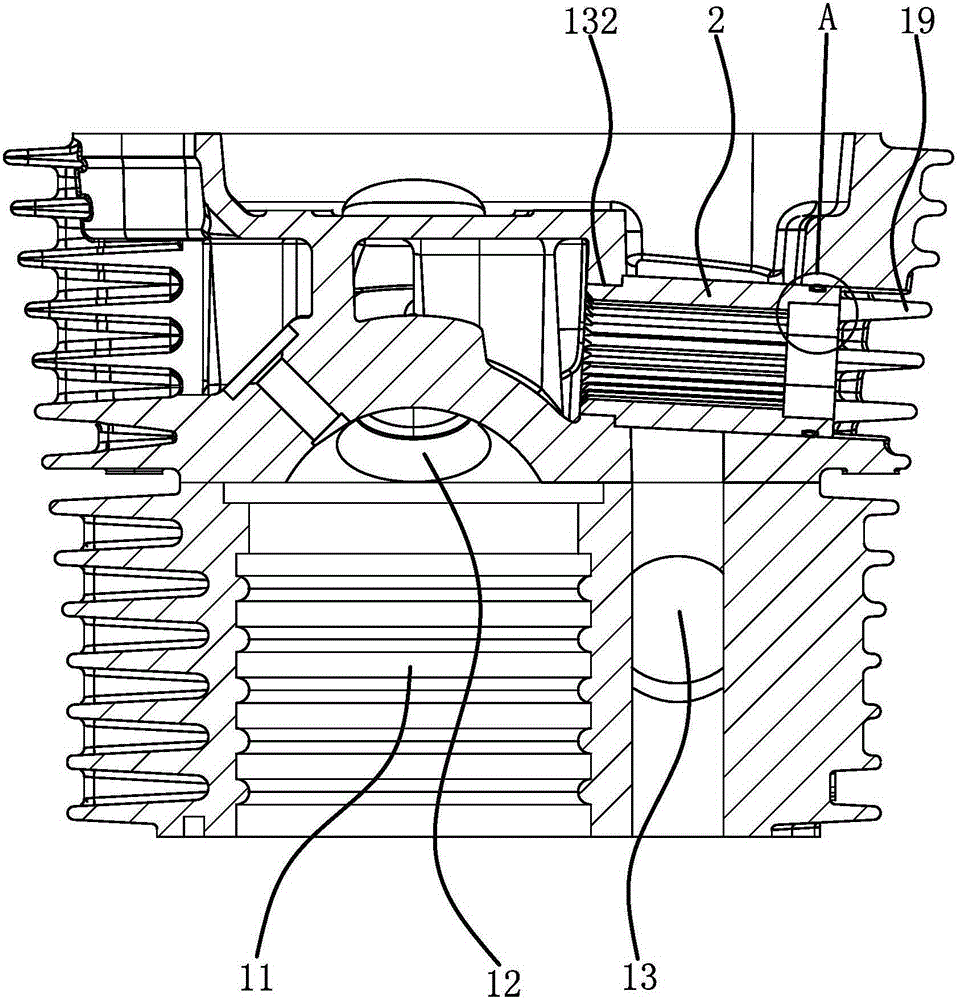

[0031] Such as figure 1 , figure 2 , image 3Shown, a kind of air-cooled structure of internal combustion engine of motorcycle, internal combustion engine comprises cylinder head 1, has combustion chamber 11, valve chamber 12 and chain chamber 13 respectively in cylinder head 1, and valve chamber 12 is positioned at the top of combustion chamber 11, is used for Combustion chamber 11 is for air supply and exhaust. The combustion chamber 11 is in the shape of a cylinder, and a large amount of heat generated by it is transferred to the periphery of the combustion chamber 11 and the periphery of the valve chamber 12. The chain chamber 13 is flat as a whole and is located between the combustion chamber 11 and the valve chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com