Comprehensive heat source system applied to fields of ships and ocean engineering

A heat source system and marine engineering technology, applied in hull ventilation/heating/cooling, ship construction, ship parts, etc., can solve problems such as underutilization, heat waste, etc., to improve utilization efficiency, increase heat production, and improve energy utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

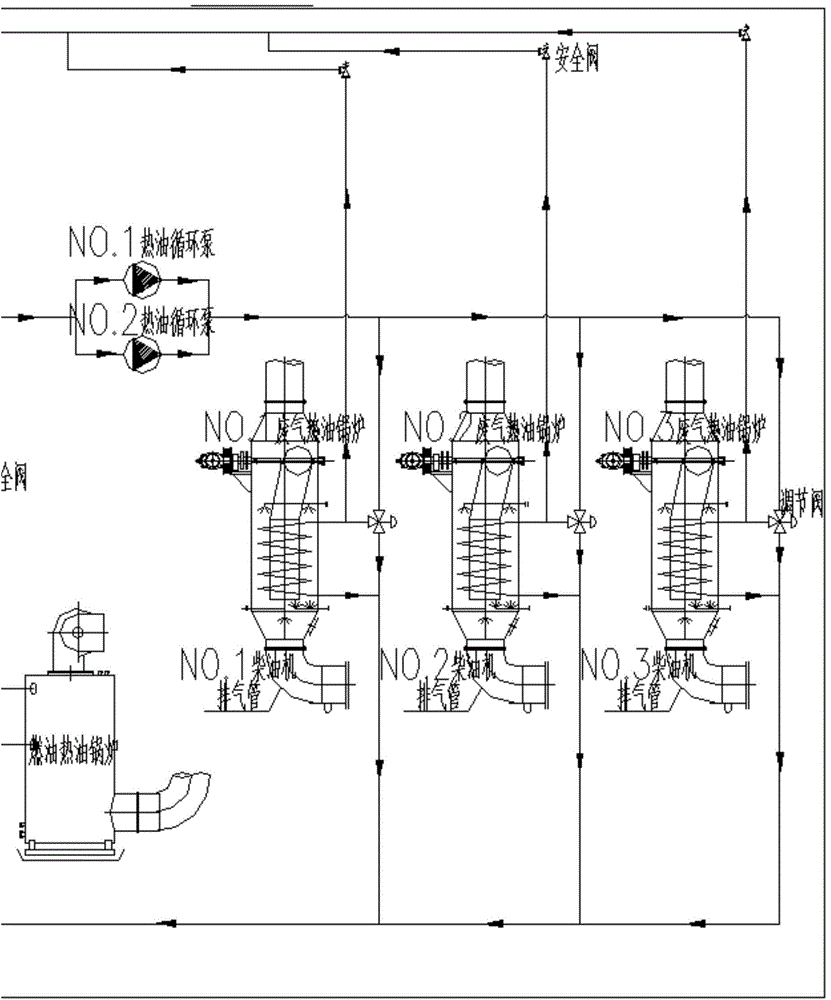

[0027] At present, the use of waste heat in typical heat source systems is limited to the exhaust of main propulsion diesel engines (such as main engines of bulk carriers, oil tankers, and container ships), and does not include the waste heat of such diesel engines cooling fresh water and diesel engines for other purposes (such as diesel engine for power generation), and a large part of heat-consuming equipment does not have high requirements for heat quality, and does not require the temperature of the heating medium to exceed 90°C. The above two factors lead to insufficient utilization of heat. In addition, when the waste heat in the exhaust gas cannot meet the operating requirements, the existing system has to supplement it by burning additional fuel, which further increases energy consumption.

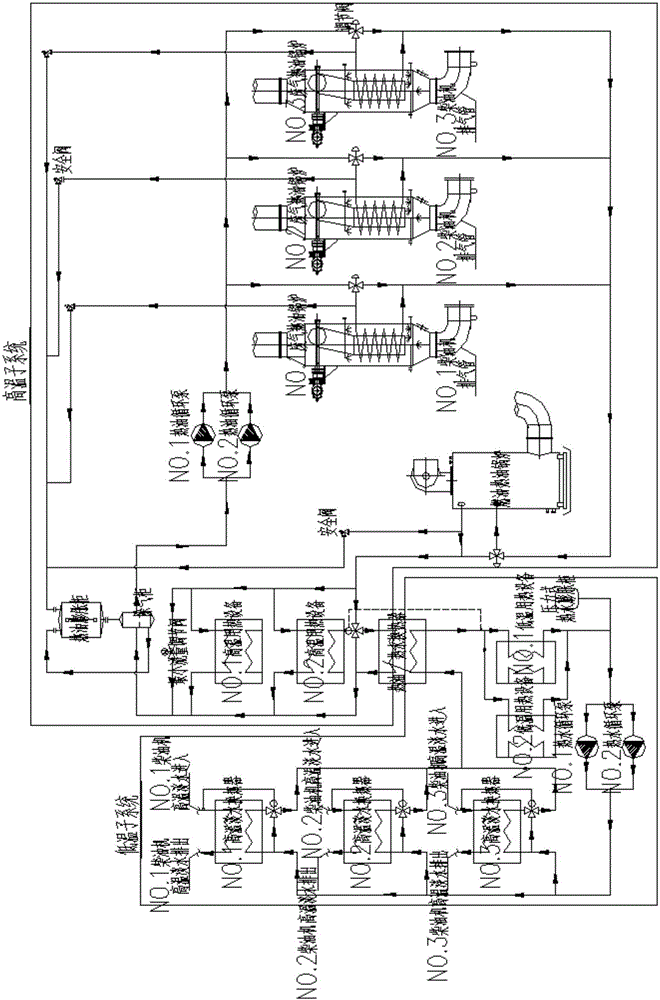

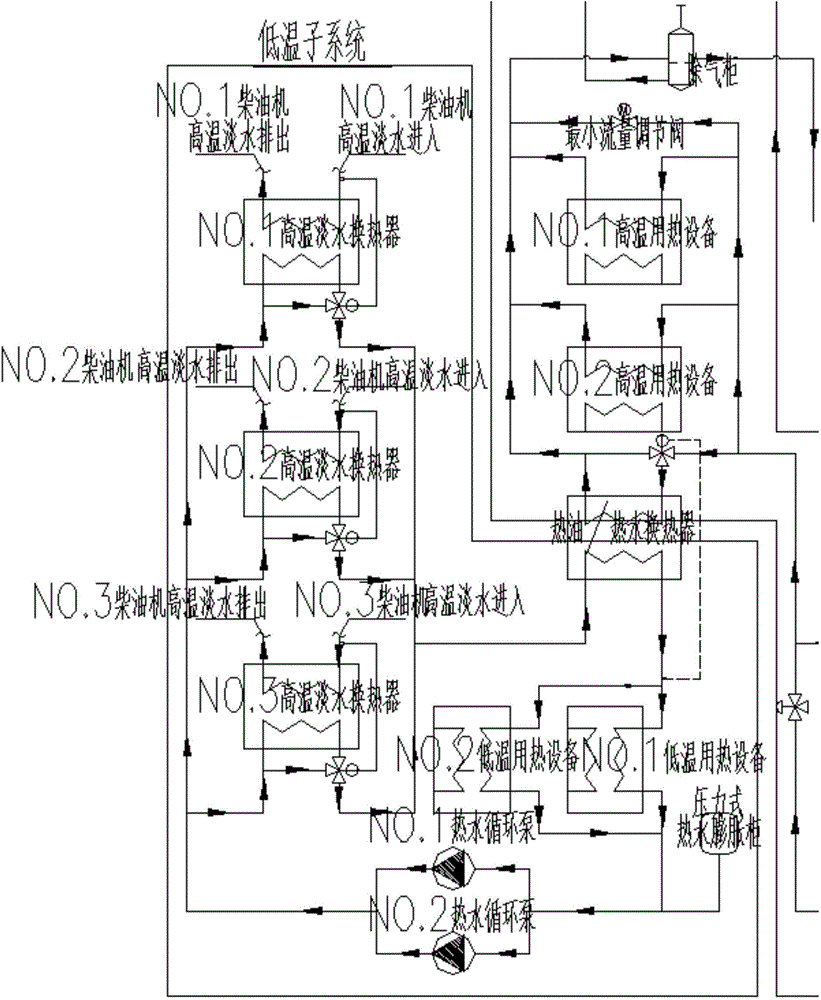

[0028] The comprehensive heat source system of the present invention divides the whole system into two parts of high temperature and low temperature according to the different requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com