Hydraulic system for rapid pressure relief of movable shears

A hydraulic system and pressure relief technology, which is applied in the field of fast pressure relief hydraulic systems for mobile shears, can solve problems affecting the stability of the shearing machine, reduce work efficiency, and slow pressure relief speed, and achieve simple structure, improve work efficiency, and reduce impact small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

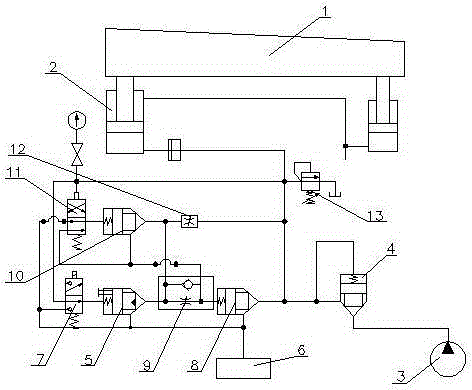

[0013] A quick pressure relief hydraulic system for mobile shears, comprising an oil cylinder 2 installed at the lower end of a tool holder 1, the oil cylinder 2 is connected to an oil supply pump 3 through a pipeline, and a hydraulic control check valve 4 is provided on the pipeline. The pipeline between the hydraulic control check valve 4 and the oil cylinder 2 is provided with a first oil return line and a second oil return line respectively connected to the plug-in throttle valve 5, and the plug-in throttle valve 5 is connected to the oil return tank 6 connected, the plug-in throttle valve 5 is connected with an electromagnetic ball valve 7, a check valve 8 is provided on the second oil return pipeline, and a one-way valve 8 is provided between the check valve 8 and the plug-in throttle valve 5. Throttle valve 9, the first oil return pipeline is directly connected to the oil return tank 6 through an oil circuit, a cartridge valve 10 is provided on the oil circuit, and the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap