Single-cylinder latch device, cylinder head assembly and crane

A single-cylinder latch and cylinder pin technology, which is applied to cranes, fluid pressure actuators, etc., can solve the problems of equipment, large labor input, large ramp size, and high synchronization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

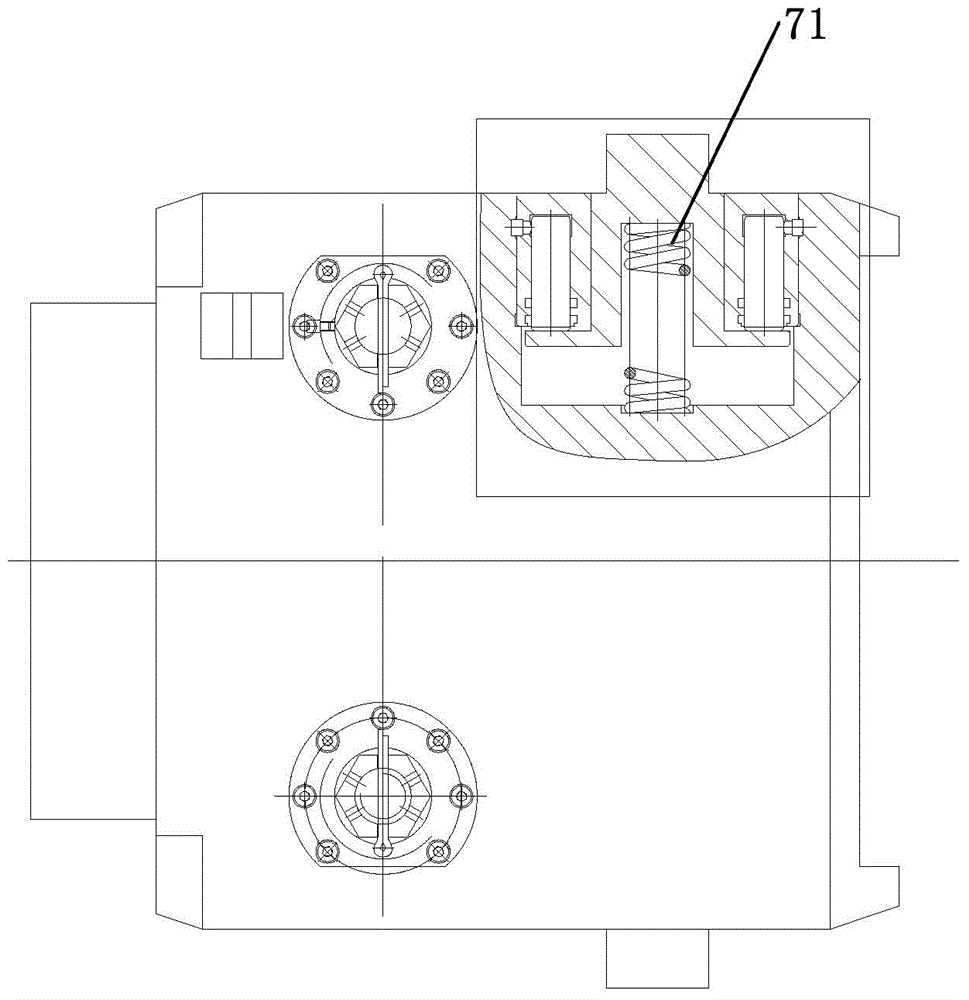

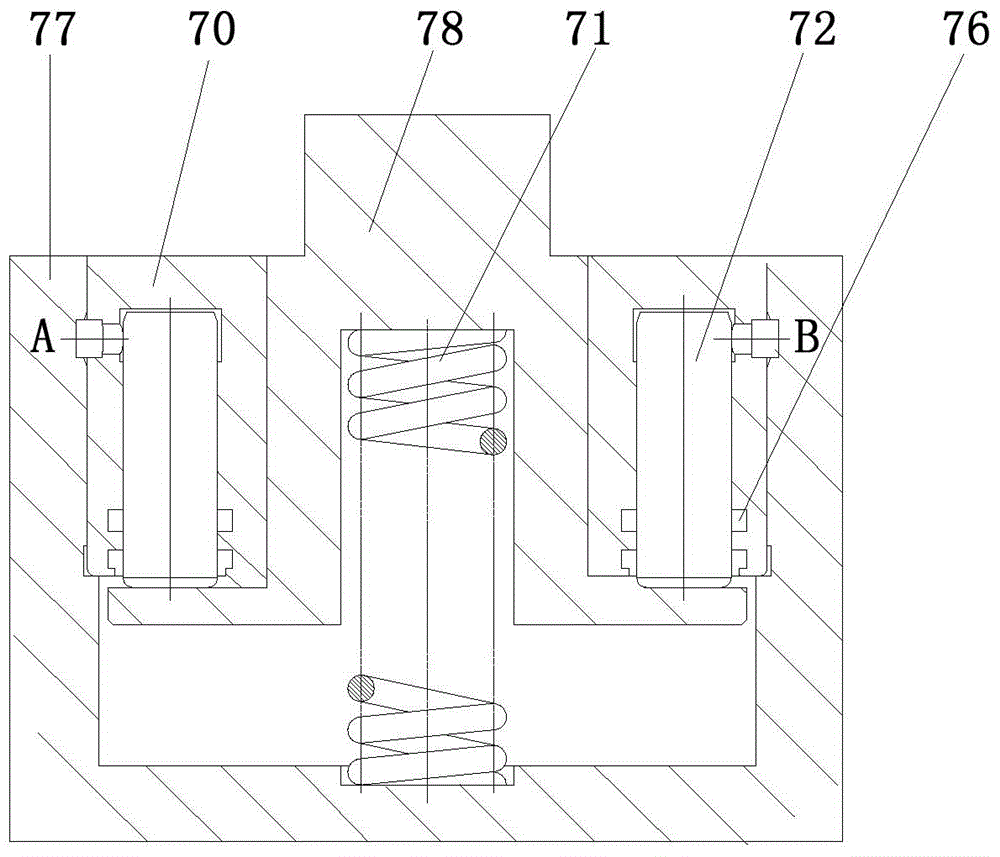

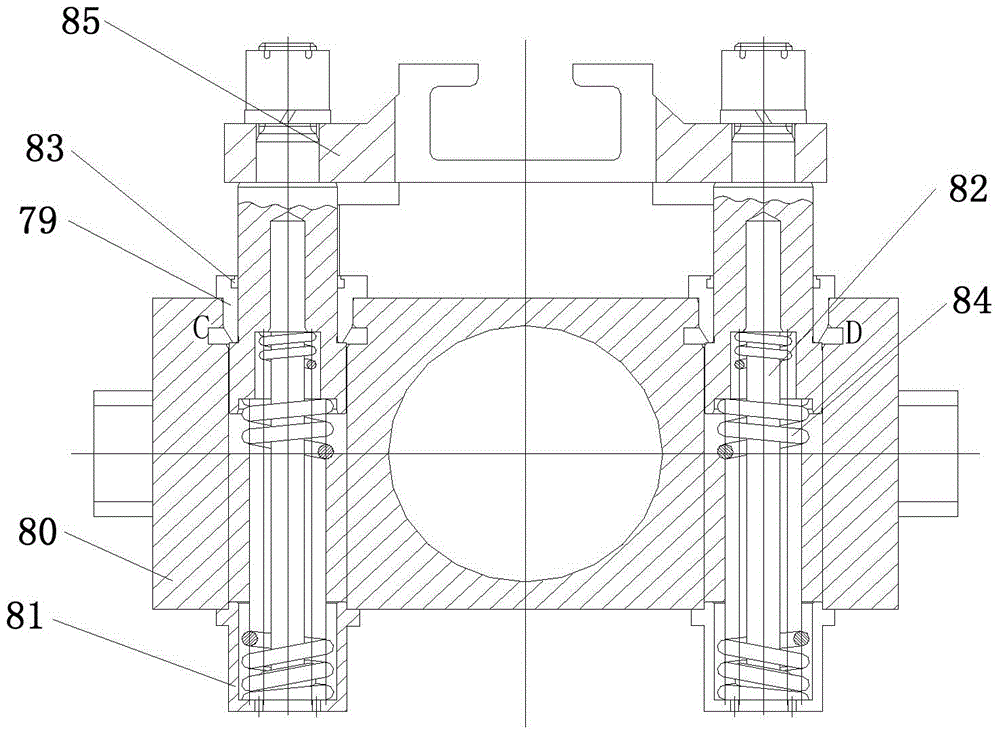

[0084] Combine below Figure 5 ~ Figure 15 A more detailed elaboration of the technical solution provided by the present invention, a technical solution obtained by replacing any technical means provided by the present invention or combining any two or more technical means or technical features provided by the present invention with each other All should be within the protection scope of the present invention.

[0085] Explanation of technical terms or nouns used in this embodiment.

[0086] Cylinder head: located at a certain position of the cylinder barrel or piston rod of the telescopic cylinder, used to control the connection and separation between the telescopic cylinder and the outrigger, and between the outrigger and the outrigger, mainly including the arm pin drive device, cylinder pin, drive Oil cylinder, position detection block, etc.

[0087] Cylinder Pin: The pin on the telescoping cylinder that acts to lock the cylinder and boom together. There are usually 2 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com