An online engine oil viscosity detection device and detection method thereof

A technology of engine oil and detection device, applied in the direction of DC flow characteristic measurement, etc., can solve the problems of error, increase of error, and unsatisfactory method for detecting viscosity, etc., and achieve the effect of scientific detection results and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

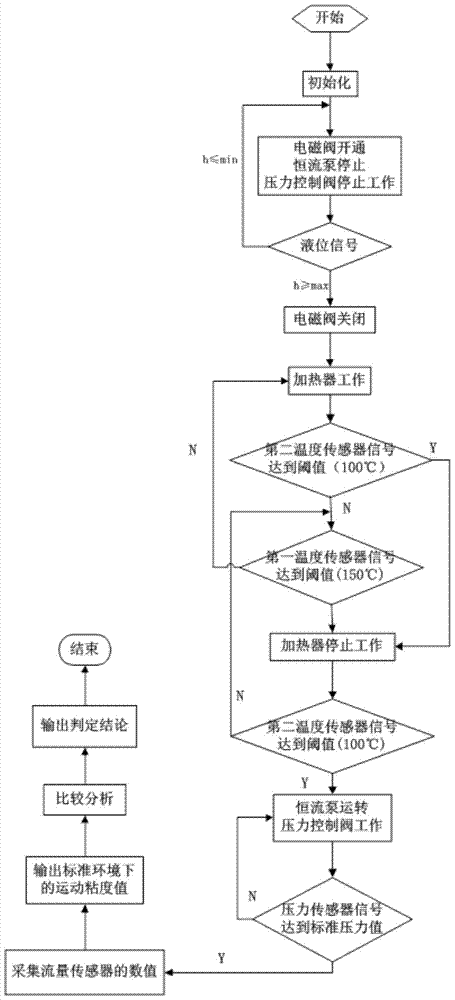

[0033] The specific embodiment of the present invention will be further elaborated below in conjunction with accompanying drawing of description:

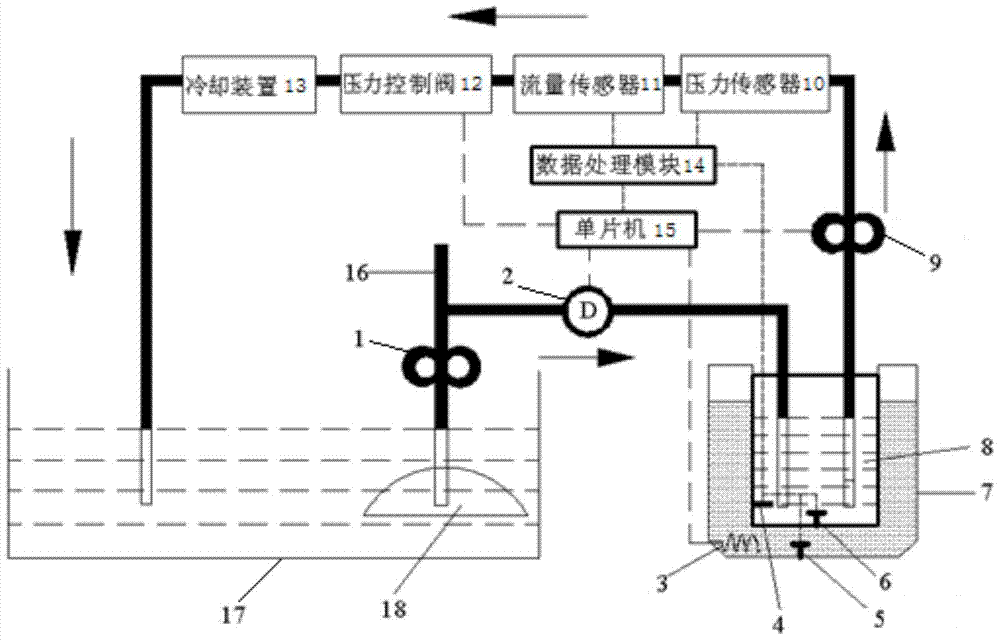

[0034] Such as figure 1 As shown, the present invention discloses an on-line detection device for engine oil viscosity. The device is installed downstream of the oil pump 1 in the lubricating oil circuit of the automobile engine, and a branch circuit is connected in parallel to the side of the main oil circuit 16, and the branch circuit is controlled by a solenoid valve. On-off branch. The device is connected to the solenoid valve 2, the oil sampling device 8, the constant flow pump 9, the pressure sensor 10, the flow sensor 11, the pressure control valve 12 and the cooling device 13 through the oil supply pipeline in sequence along the direction of oil transmission;

[0035] The solenoid valve 2 is installed on a branch connected in parallel with the main oil circuit 16, and at the inlet of the sampling device, its downstream end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com