Contactor synchronous detector and use method thereof

A technology of synchronous detection and contactor, applied in the direction of circuit breaker testing, etc., can solve problems such as equipment accidents, main contact welding, three-phase main contact closure asynchronous, etc., to achieve the effect of solving equipment damage and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

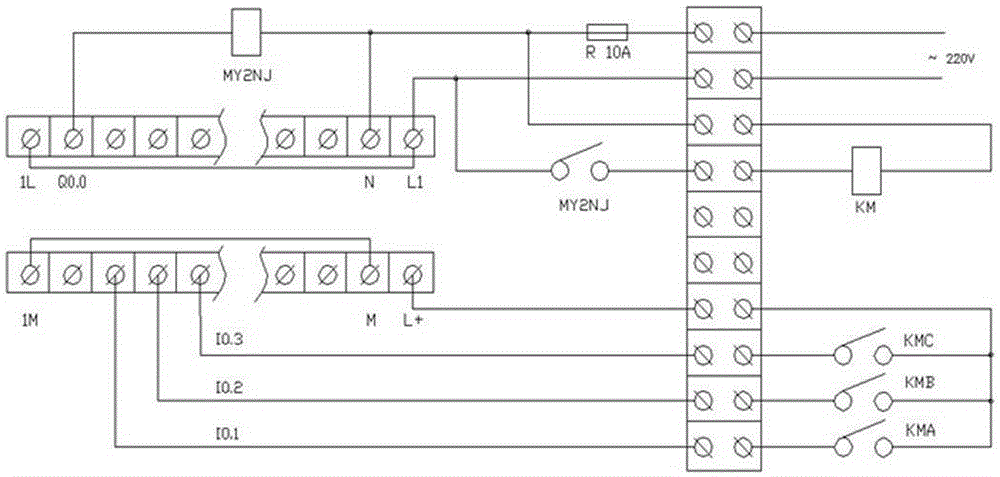

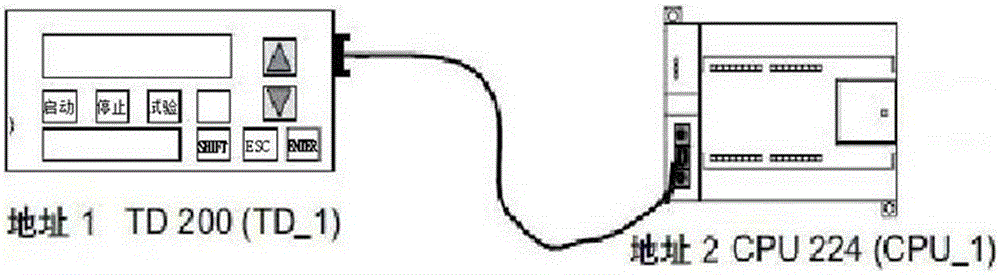

[0020] The contactor synchronous detector includes a display unit and a test unit, and the display unit is connected with the test unit. The test unit includes a programmable controller and a test circuit. One of the three moving contacts and three static contacts of the contactor KM is connected to the input common terminal L+ of the programmable controller, and the other contact is respectively connected to the programmable controller. The input terminals I0.1, I0.2 and I0.3 of the programming controller are connected.

[0021] The intermediate relay MY2NJ is connected between the output terminal Q0.0 and the N terminal, and the contactor KM and the normally open contact of the intermediate relay MY2NJ are connected in series to the AC power supply. The display unit includes a text display, and the text display is connected with the programmable controller through a communication data line.

[0022] The programmable controller adopts Siemens S7-200 CPU224, the text display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com