Blue-phase liquid crystal display, blue-phase liquid crystal display module and manufacture method thereof

A blue-phase liquid crystal and display module technology, which is applied in instruments, nonlinear optics, optics, etc., can solve the problem of high driving voltage of blue-phase liquid crystal, and achieve the effect of reducing the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

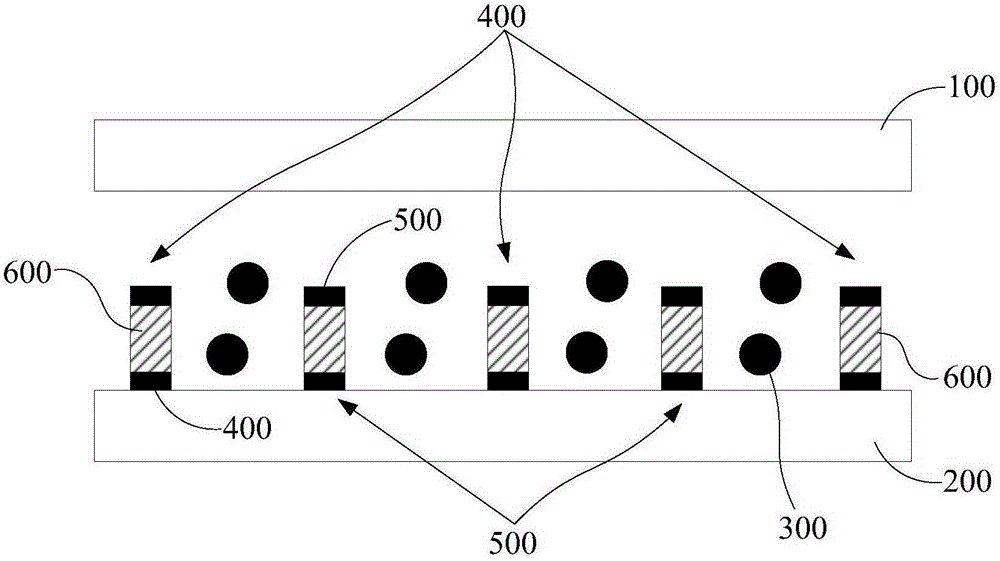

[0039] see figure 1 , figure 1 It is a cross-sectional view of the first embodiment of the blue-phase liquid crystal display module of the present invention; the blue-phase liquid crystal display module includes but not limited to the following components: an upper substrate 100, a lower substrate 200, a blue-phase liquid crystal 300, and an upper substrate 100 and a plurality of common electrodes 500 and pixel electrodes 400 between the lower substrate 200 .

[0040] Specifically, the lower substrate 200 is disposed opposite to the upper substrate 100 . The blue-phase liquid crystal 300 is disposed between the upper substrate 100 and the lower substrate 200, wherein the lower substrate 200 is alternately provided with pixel electrodes 400 and common electrodes 500 at intervals, and an electric field is formed between the pixel electrodes 400 and the common electrodes 500 to drive the blue-phase liquid crystal 300 .

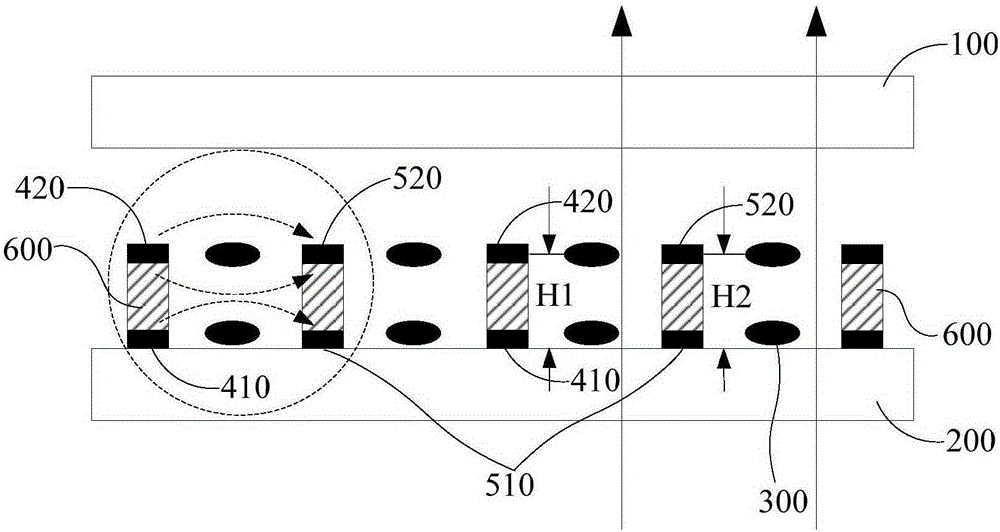

[0041] Please also refer to figure 1 with figure 2 , ...

Embodiment 2

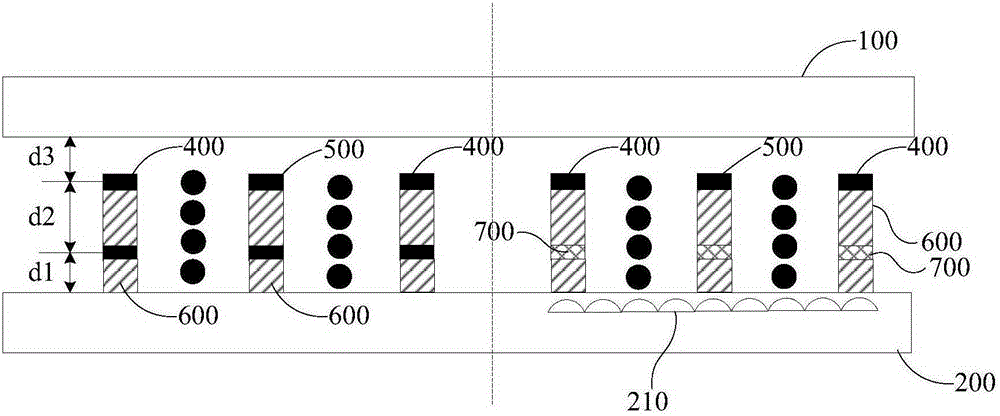

[0046] see image 3 , image 3 It is a cross-sectional view of the second embodiment of the blue-phase liquid crystal display module of the present invention. In this embodiment, the lower substrate 200 is provided with a reflective layer 210 to divide the display module into a transmissive area and a reflective area, wherein the left side of the dotted line is a transmissive area, and the right side of the dotted line with the reflective layer 210 is a reflective area. Both the pixel electrode 400 and the common electrode 500 in the transmission area have a two-layer structure, the first layer is disposed on the lower substrate 200 through the insulating layer 600 , and the second layer is disposed at intervals from the first layer through the insulating layer 600 .

[0047] Preferably, the first layer of the pixel electrode 400 and the common electrode 500 are on the same plane, and the second layer of the pixel electrode 400 and the common electrode 500 are on the same pla...

Embodiment 3

[0053] Further preferably, please also refer to Figure 6 with Figure 7 , Figure 6 It is a cross-sectional view of the third embodiment of the blue-phase liquid crystal display module of the present invention, Figure 7 It is a schematic cross-sectional view of a modified embodiment of the third embodiment. In the previous embodiment, the discarded electrode layer does not pass through the signal, but the display effect may be affected due to the capacitive coupling effect. Therefore, in this embodiment, the discarded electrode layer is not directly fabricated, but the pixel electrode 400 and the common electrode 500 in the reflective area It is directly connected to the lower substrate 200 through the insulating layer 600 .

[0054] Preferably, the pixel electrode 400 and the common electrode 500 in the reflection area are on the same plane as the first layer electrode structure or the second layer electrode structure of the pixel electrode and the common electrode in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com