Magnetized plasma fusion ignition device and inertial magnetic confinement fusion method

A magnetic confinement fusion and plasma technology, used in fusion reactors, thermonuclear fusion reactors, climate sustainability, etc. problem, to achieve stable life, high temperature and density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

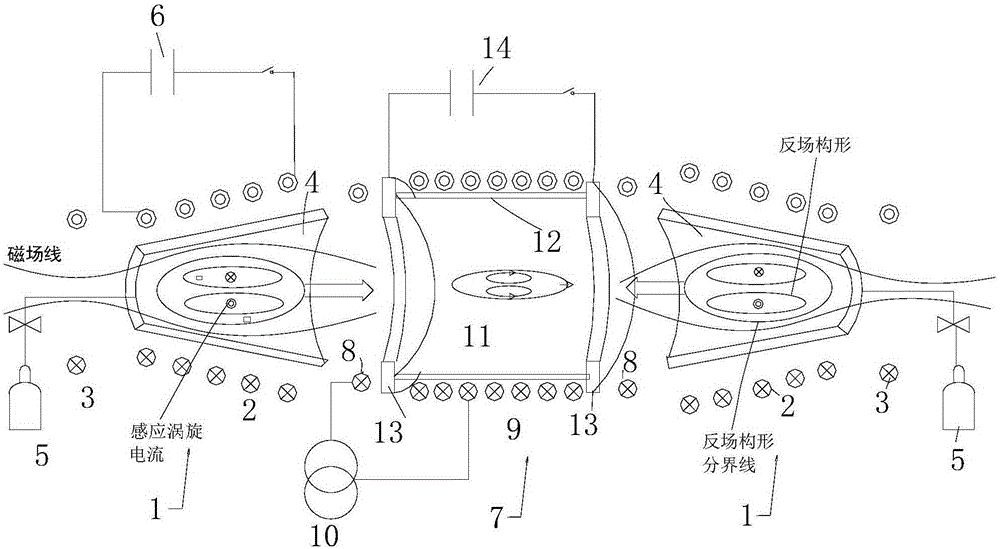

[0026] Such as figure 1 Shown is the magnetized plasma fusion ignition device of the present invention. All components of the device are placed in a vacuum state, which includes the formation of the anti-field configuration plasma cluster and the accelerated transmission system 1, which also includes the collision fusion of the plasma target The system and the implosion compression system 7 of the plasma target, the forming and accelerating transmission system 1 are symmetrically distributed on both sides of the collision fusion system and the implosion compression system 7; the collision fusion system includes: a metal sleeve 12, the metal sleeve The outer side of 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com