Direct current motor

A DC motor and casing technology, applied in the field of rare-earth disc DC motors, can solve problems such as failure to work or burnout, high contact resistance, and melting of solder on the circuit breaker ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

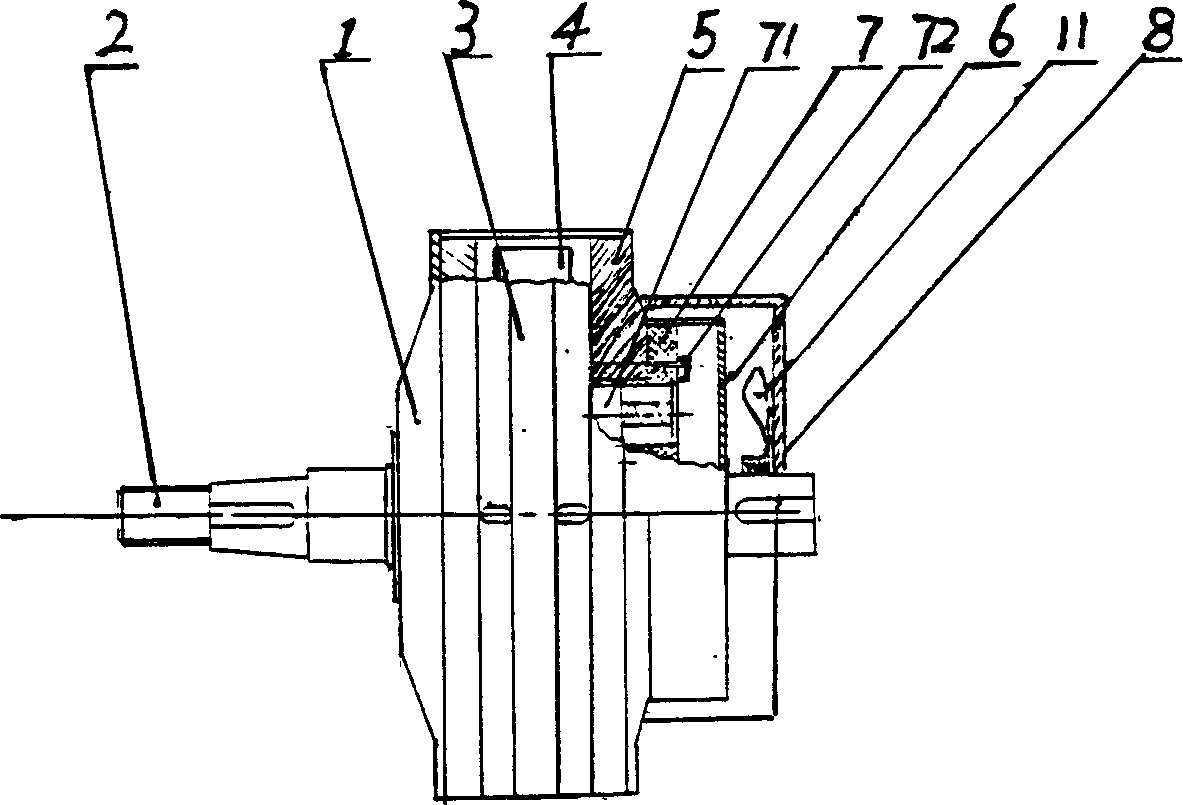

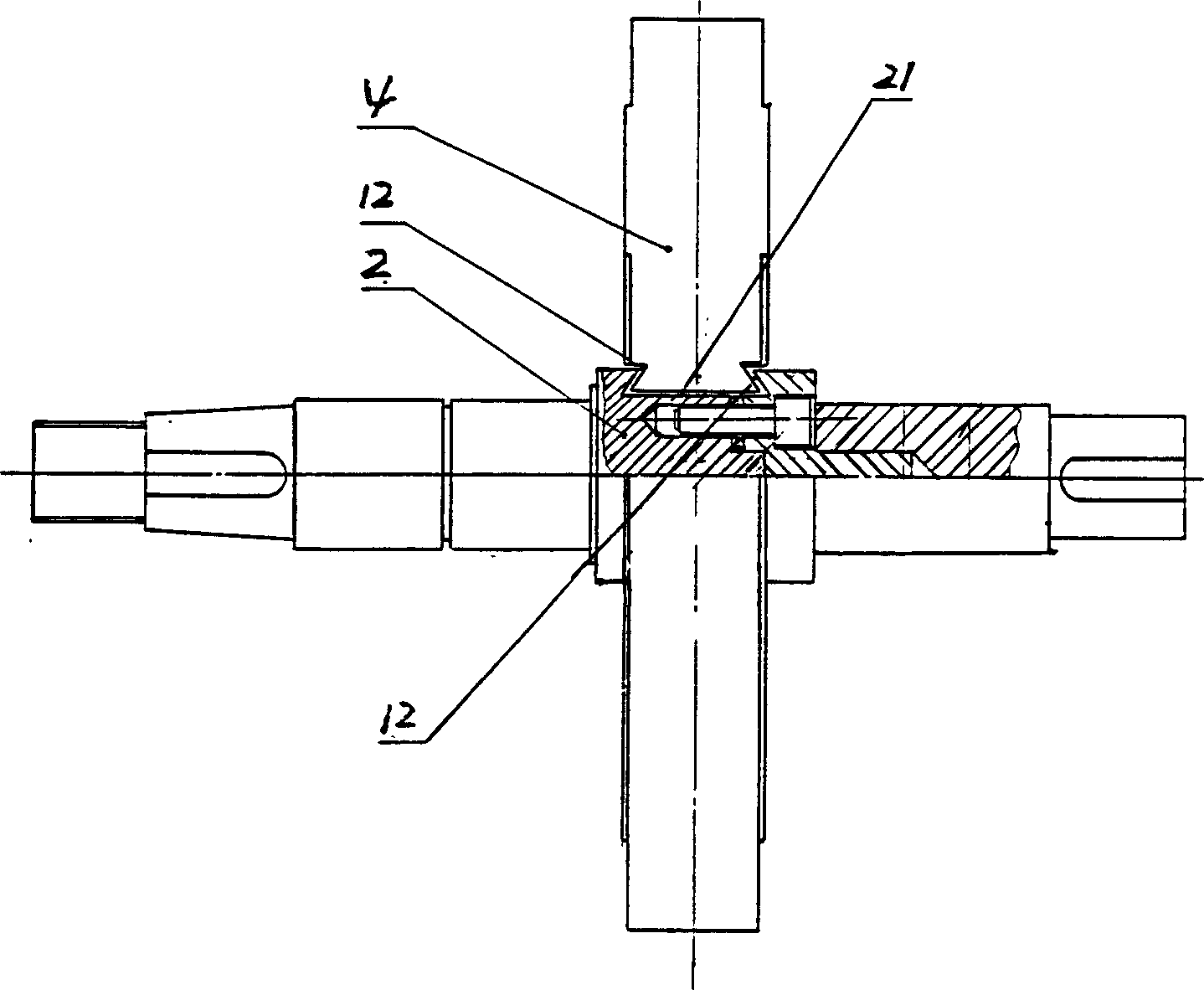

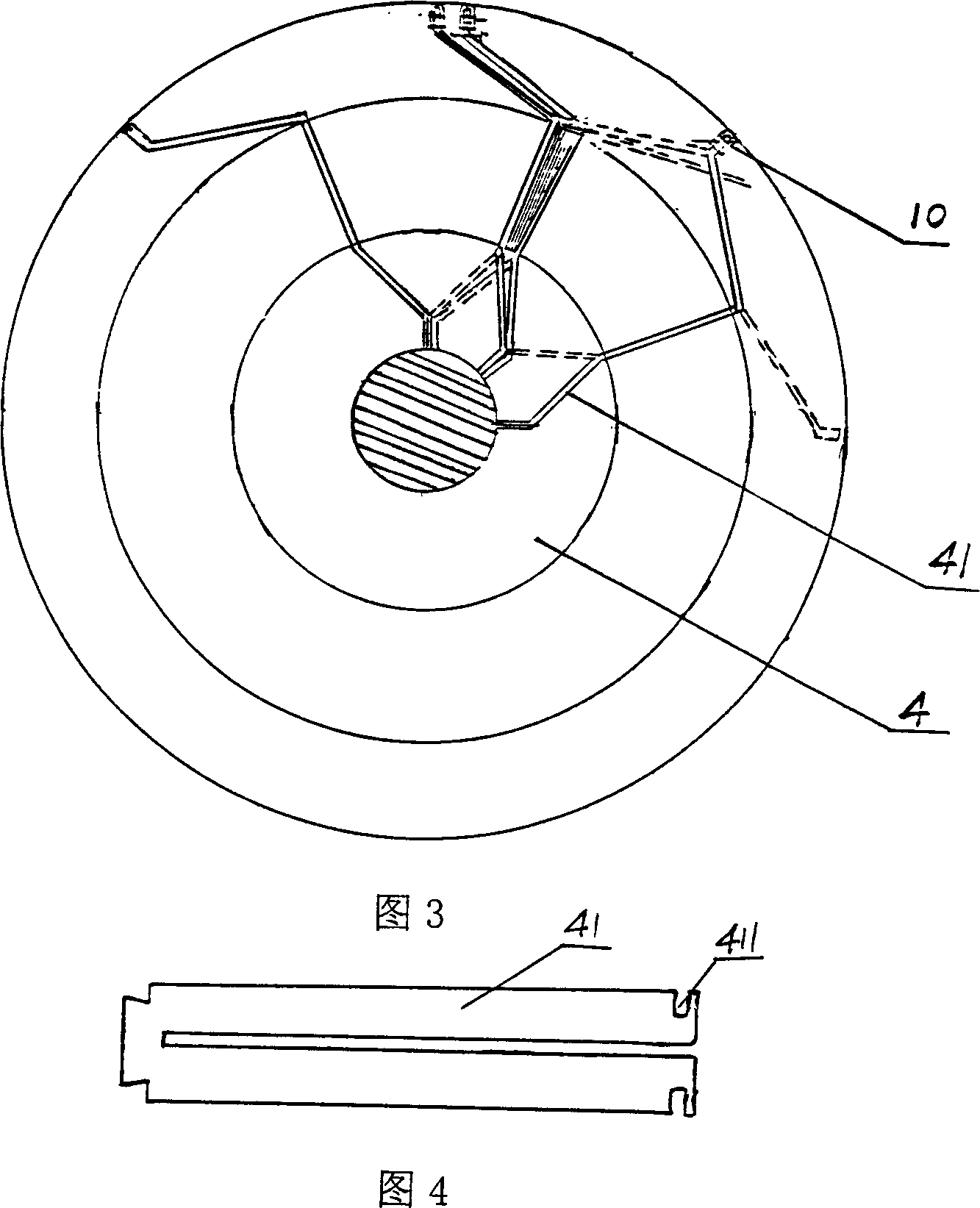

[0022] Embodiment one, Figures 1 to 9 Among them, the DC motor of the present invention is composed of a front end cover 1, a rotating shaft 2, a casing 3, a rotor 4, a rear end cover 5, a carbon brush box cover 6, a carbon brush box 7, a rear casing 8, etc., wherein the casing 3 It is stamped and formed by cold-rolled plate, and there are two rows of ventilation holes with front and back wings. The polygonal magnetic steel 9 is equipped with a rotating shaft 2 at the center of the front end cover 1. The rotating shaft 2 is equipped with a rotor winding and a rotor core assembly to form a rotor 4. The rotor winding and rotor iron core assembly is composed of a herringbone copper sheet 41 and A stack of silicon steel sheets 42 is installed between each copper sheet 41, and the number of copper sheets 41 is 127 pieces. The short circuit strips 10 snap together the copper sheets 41 according to regulations to form the rotor winding.

[0023] The right end of the casing 3 is co...

Embodiment 2

[0024] Embodiment two, such as Figure 10 As shown, the carbon brush box 7 and the carbon brush 71 are installed on the casing 3, that is, the outer end of the copper sheet 41 composing the rotor 4 is selected as a commutator (commutator), then every two adjacent short circuit bars 10 Just must fill insulating material again, and require that outer circle just should be made very round, and other is consistent with embodiment one.

[0025] After the two copper screws on the end cover are connected to the power supply, the current flows through the brushes in the rotor winding, and the torque is generated under the action of the stator magnetic steel to start rotating. If the positive and negative poles of the input power are changed, the motor will reverse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com