Method for detecting degree of cleanliness of reactor core fuel assembly

A technology for a fuel assembly and a detection method, which is applied in the field of cleanliness detection, can solve problems such as the difficulty in determining the surface contamination of the fuel assembly, and achieve the effects of solving the difficulty in determining the surface contamination, being easy to operate, and having a simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

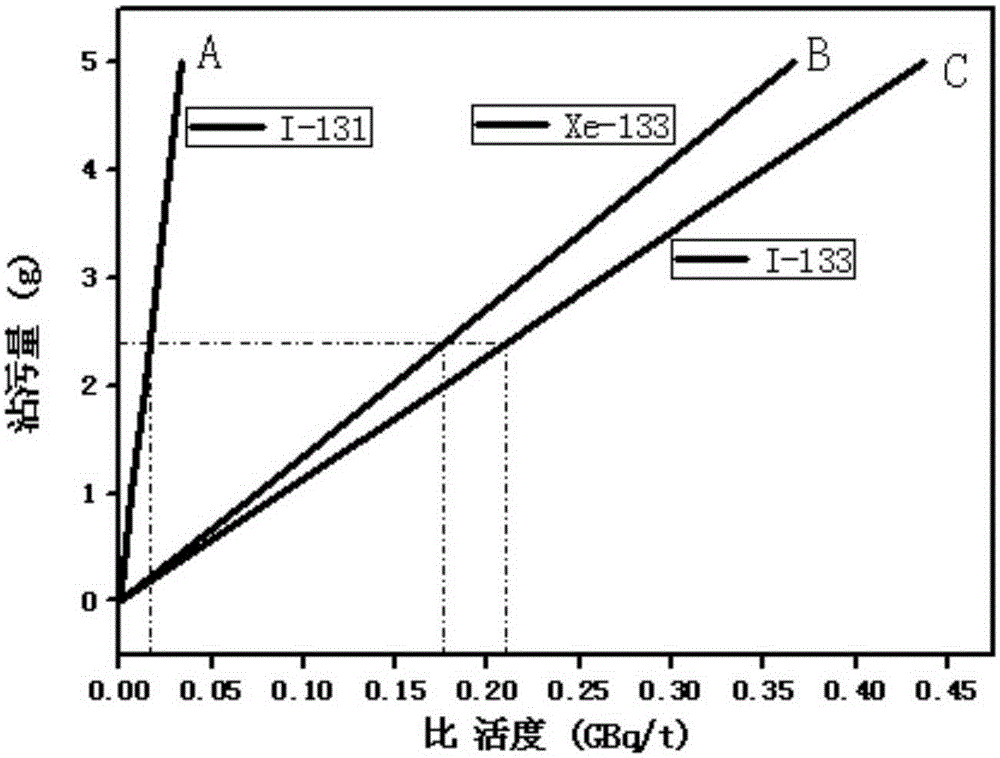

[0026] The method for detecting the cleanliness of the core fuel assembly provided by the present invention firstly uses the method of combining theoretical calculation with the actual measurement of the fission product source term of the main circuit of the power plant, and then combines the calculated source term of the main circuit with the measured part The source terms of nuclides can be compared and analyzed, and finally the total amount of contamination of the fuel assembly surface by the new fuel during the manufacturing process can be quickly determined.

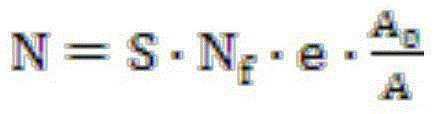

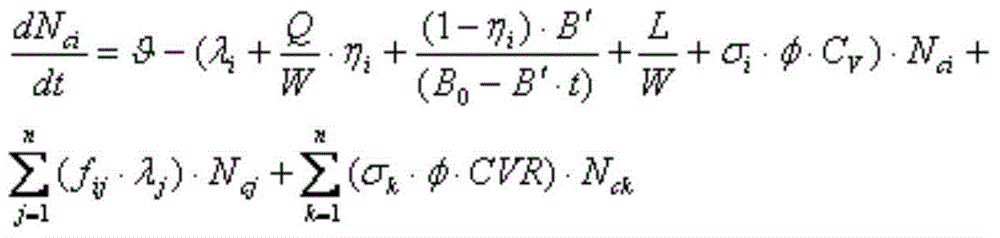

[0027] Among them, the calculation method of the total amount of surface contamination of the core fuel assembly, the specific theoretical calculation process is as follows:

[0028] Firstly, the contaminating surface area of a single fuel rod is calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com