Method for improving hardening of texture of protein bars in storage process

A protein bar and texture technology, applied in the fields of application, food preparation, food science, etc., can solve the problem of hardening of protein bar texture that has not yet been improved, and achieve the effect of simple and safe improved formula, obvious improvement effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for improving the texture hardening of protein bars during storage by using xanthan gum, the technical scheme adopted is:

[0023] 1) Preparation of mixed gum system containing 0.2% xanthan gum

[0024] First, 0.02g of xanthan gum was dissolved in 1.25g of ultrapure water, then 2.5g of sorbitol and 1.75g of glycerin were added for heating, stirring and dissolving to make a uniform colloidal mixture.

[0025] 2) Preparation of casein bar model system containing 0.2% xanthan gum

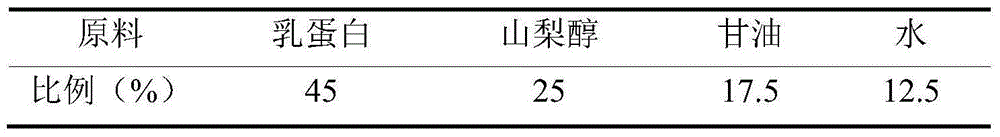

[0026] The formula of the protein bar model system is shown in Table 1.

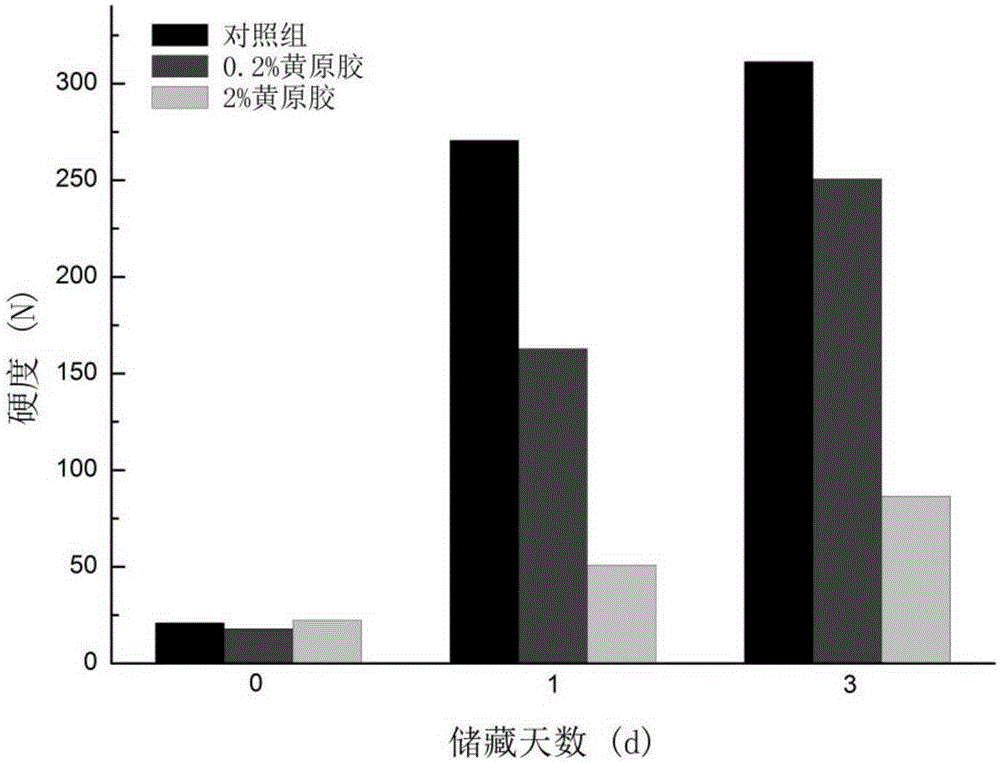

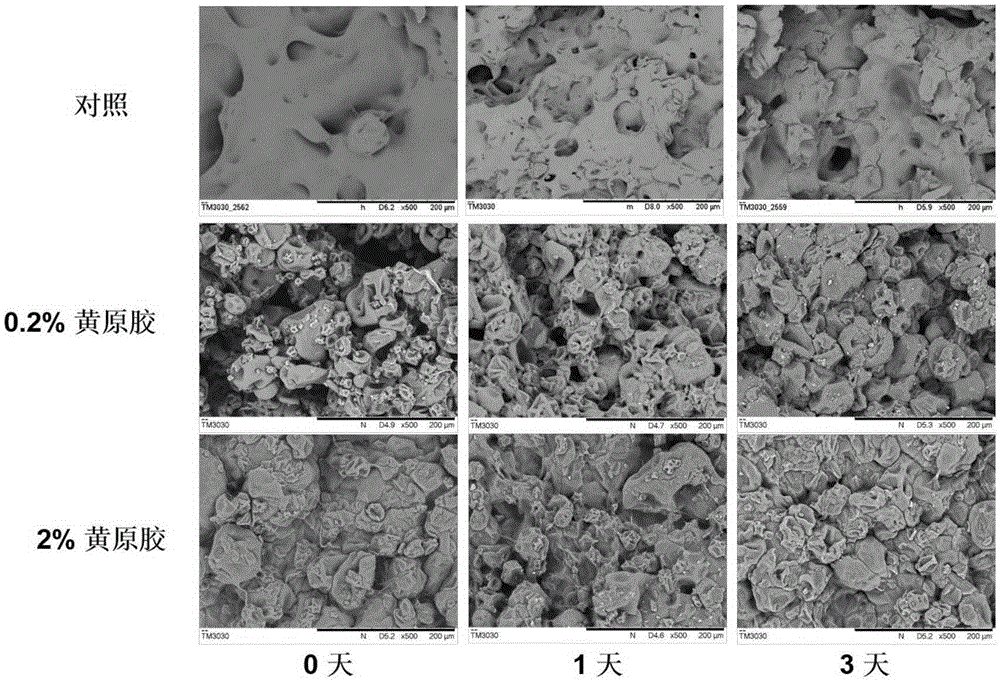

[0027] In the present invention, the specific experimental steps are as follows: 5.52 g of mixed gum containing 0.2% xanthan gum and 4.5 g of casein powder were mixed and kneaded for 5 minutes to form a uniform dough. Finally, store the kneaded casein bars airtight to prevent water loss. After the sample to be tested was equilibrated at room temperature for 1 hour, samples were taken on days 0, 1, and 3.

[...

Embodiment 2

[0035] A method for improving the texture hardening of protein bars during storage by using xanthan gum, the technical scheme adopted is:

[0036] 1) Preparation of a mixed gum system containing 2% xanthan gum

[0037] First, 0.2g xanthan gum was dissolved in 1.25g ultrapure water, then 2.5g sorbitol and 1.75g glycerin were added for heating, stirring and dissolving to make a uniform colloidal mixture.

[0038] 2) Preparation of casein bar model system containing 2% xanthan gum

[0039] The formula of the protein bar model system is shown in Table 1.

[0040] In the present invention, the specific experimental steps are as follows: 5.7 g of mixed gum containing 2% xanthan gum and 4.5 g of casein powder were mixed and kneaded for 5 minutes to form a uniform dough. Finally, store the kneaded casein bars airtight to prevent water loss. After the sample to be tested was equilibrated at room temperature for 1 hour, samples were taken on days 0, 1, and 3.

[0041] 3) Texture a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com