Angelica sinensis anti-wrinkle cream and preparation method thereof

An anti-wrinkle cream and angelica technology, applied in the field of skin care products, can solve the problems of skin inflammation and rash, easy oxidation of active ingredients, decreased skin resistance, etc., to promote the production of free radical scavenging enzymes, increase shelf life, and heal. The effect of increased regeneration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

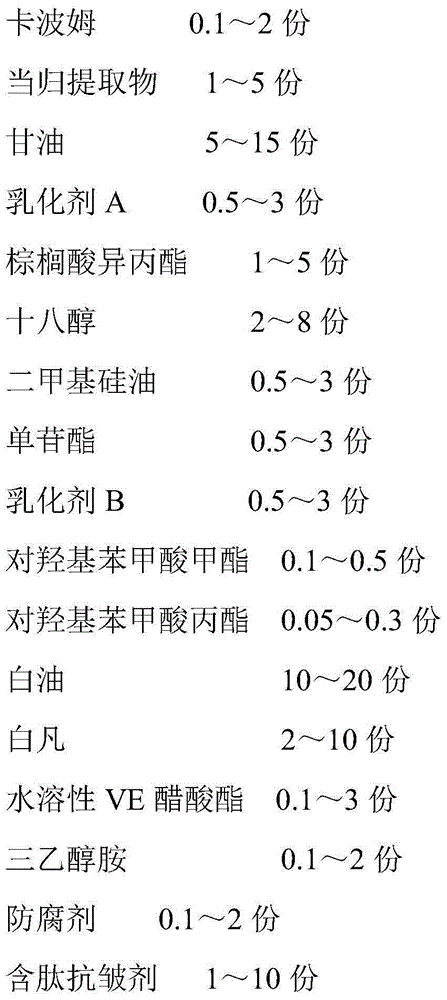

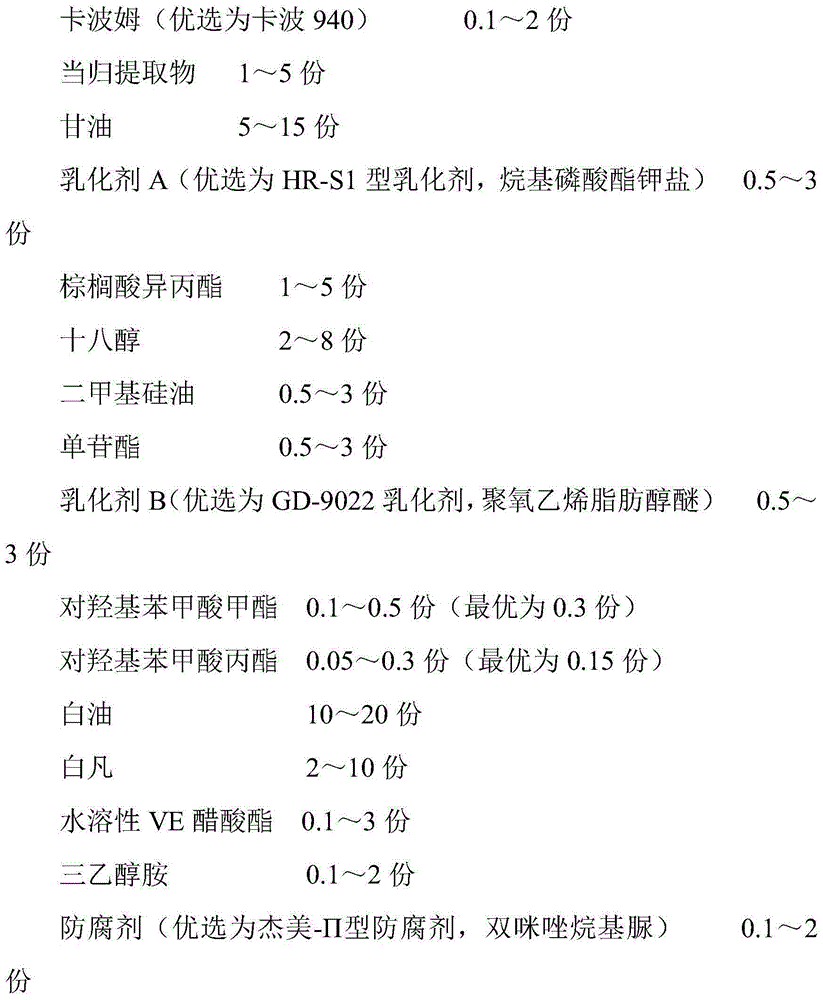

Method used

Image

Examples

Embodiment 1

[0042] Add pure water or mineral water into the emulsification pot, stir 2 parts of carbomer until completely dissolved, then raise the temperature to 80°C and keep stirring at constant temperature for 15 minutes, add 5 parts of angelica extract, 5 parts of glycerin and 0.5 part of emulsifier A , insulated and stirred for 15 minutes to obtain the first reaction solution.

[0043] 5 parts of isopropyl palmitate, 2 parts of stearyl alcohol, 0.5 parts of simethicone, 3 parts of monoglycoside ester, 0.5 parts of emulsifier B, 0.5 parts of methyl p-hydroxybenzoate, 0.05 parts of propyl p-hydroxybenzoate Ester, 10 parts of white oil and 10 parts of white vanilla were added into a reaction vessel and stirred to raise the temperature to 80°C at a heating rate of 3°C / 5min, and kept stirring for 20min to obtain the second reaction solution.

[0044] Vacuum the emulsification pot to -0.06Mpa, add the second reaction solution and mix evenly, keep stirring for 30 minutes, cool down to 55°C...

Embodiment 2

[0046] Add pure water or mineral water into the emulsification pot, stir 1 part of carbomer until completely dissolved, then raise the temperature to 75°C and keep stirring at constant temperature for 10 minutes, add 3 parts of angelica extract, 10 parts of glycerin and 2 parts of emulsifier A , and kept stirring for 8 minutes to obtain the first reaction solution.

[0047] 3 parts of isopropyl palmitate, 8 parts of stearyl alcohol, 3 parts of simethicone, 3 parts of monoglycoside ester, 2 parts of emulsifier B, 0.3 parts of methyl p-hydroxybenzoate, 0.15 parts of propyl p-hydroxybenzoate Ester, 20 parts of white oil and 2 parts of white vanilla were added into a reaction vessel and stirred to raise the temperature to 75°C at a heating rate of 2°C / 5min, and kept stirring for 15min to obtain the second reaction solution.

[0048] Vacuum the emulsification pot to -0.06Mpa, add the second reaction solution and mix evenly, keep stirring for 18 minutes, cool down to 60°C, add 2 par...

Embodiment 3

[0050] Add pure water or mineral water into the emulsification pot, stir 0.1 part of carbomer until it is completely dissolved, then raise the temperature to 75-80°C and keep stirring at constant temperature for 8 minutes, and emulsify 1 part of angelica extract, 15 parts of glycerin and 3 parts Reagent A was incubated and stirred for 8 minutes to obtain the first reaction solution.

[0051] 3 parts of isopropyl palmitate, 5 parts of stearyl alcohol, 2 parts of simethicone, 0.5 parts of monoglycoside ester, 3 parts of emulsifier B, 0.1 part of methyl paraben, 0.05 part of propyl paraben , 13 parts of white oil and 5 parts of white vanilla were added into a reaction vessel and stirred to raise the temperature to 78° C. at a heating rate of 2° C. / 5 min, and kept stirring for 13 minutes to obtain the second reaction liquid.

[0052] Vacuum the emulsification pot to -0.05Mpa, add the second reaction solution and mix evenly, keep stirring for 15 minutes, cool down to 55°C, add 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com