Strontium barium niobate series photo-catalyst normal-temperature degradation hydrocarbon compound

A photocatalyst, barium strontium niobate technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

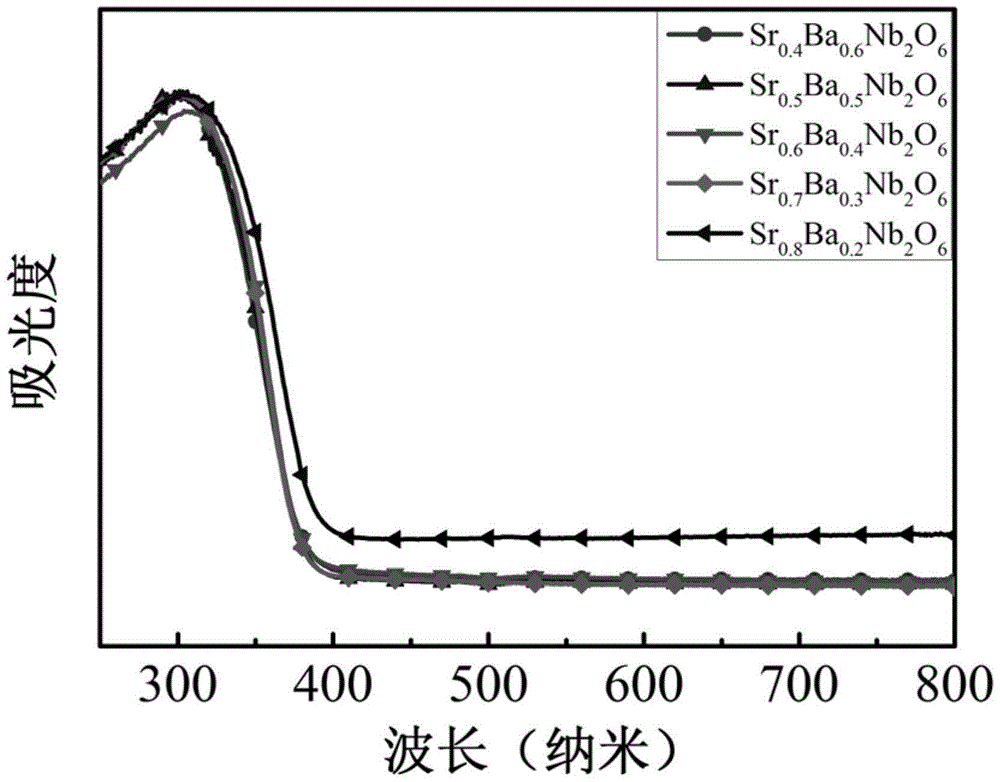

[0022] This example provides a ywt%M-Sr x Ba 1-x Nb 2 o 6 A series of photocatalysts, the composition of which is represented by the following formula: Sr x Ba 1-x Nb 2 o 6 , where the value of x is 0.4-0.8, and the value of y is 0. The preparation method is as follows:

[0023] SrCO 3 、BaCO 3 , Nb 2 o 5 And KCl is mixed according to the corresponding metering coefficient ratio, then added with ethanol and ball milled to form a uniform suspension. Dry the suspension to obtain a mixed powder, then transfer it to an alumina crucible, place it in a muffle furnace for 1373K heat treatment for 3 hours, and obtain Sr x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8) powder. Wash with secondary water and ethanol for 3 times to remove the molten salt and obtain pure Sr x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8) photocatalyst, ground for use.

Embodiment 2

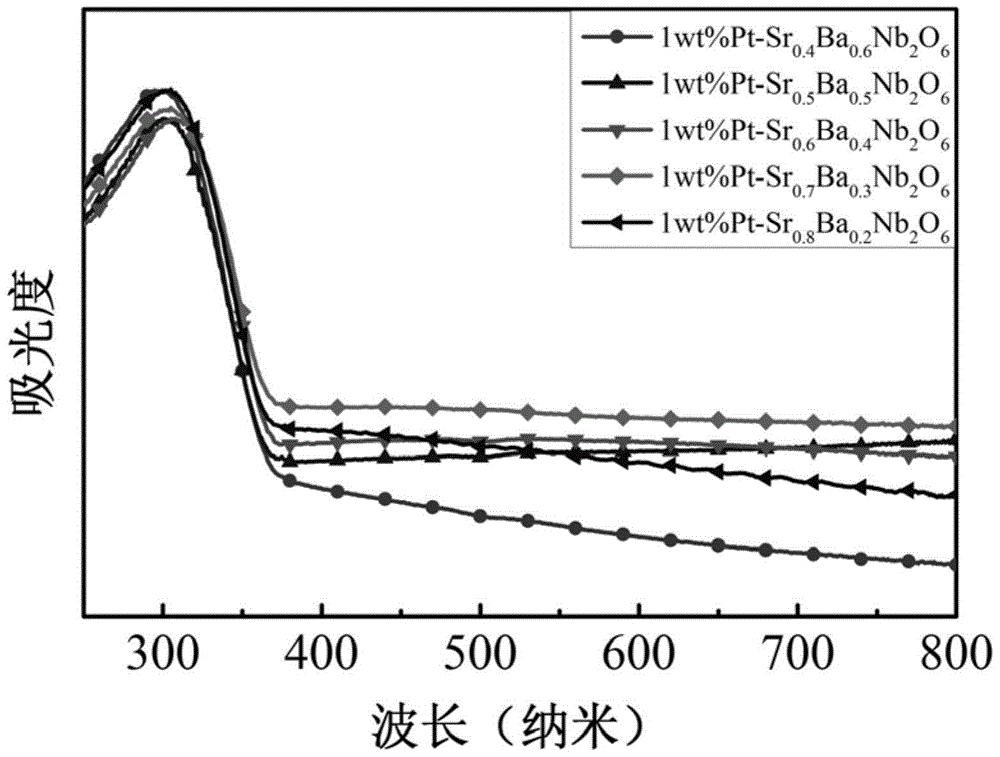

[0025] This example provides a ywt%M-Sr x Ba 1-x Nb 2 o 6 A series of photocatalysts, the composition of which is represented by the following formula: ywt%Pt-Sr x Ba 1-x Nb 2 o 6 , where M is Pt, the value of x is 0.4-0.8, and the value of y is 0.5-4. The preparation method is as follows:

[0026] Take by weighing the Sr prepared by embodiment 1 respectively x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8) catalyst 0.2g, add 150mL20% methanol solution, and the corresponding concentration of H 2 PtCl 6 Samples were obtained after 10 h of light exposure. After washing 3 times with deionized water and alcohol, dry to obtain ywt% Pt-Sr x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8,0.5≤y≤4) series of photocatalysts. Example 3:

Embodiment 3

[0027] This example provides a ywt%M-Sr x Ba 1-x Nb 2 o 6 A series of photocatalysts, the composition of which is represented by the following formula: ywt%Ag-Sr x Ba 1-x Nb 2 o 6 , where M is Ag, the value of x is 0.4-0.8, and the value of y is 1. The preparation method is as follows:

[0028] Take by weighing the Sr prepared by embodiment 1 respectively x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8) Catalyst 0.2g, add 150mL20% methanol solution, and corresponding concentration of AgNO 3 , the sample was obtained after 10 h of light. 1wt% Ag-Sr x Ba 1-x Nb 2 o 6 (0.4≤x≤0.8) series of photocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com