Closed loop control system and closed loop control method for ball mill-cyclone group

A cyclone group and closed-circuit control technology, which is applied in the field of mineral processing plant control, can solve the problems of unqualified overflow particle size of the cyclone group, unqualified overflow index of the ball cyclone group, and inaccurate and timely control, etc., to achieve saving Labor costs, qualified indicators, and timely and accurate adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

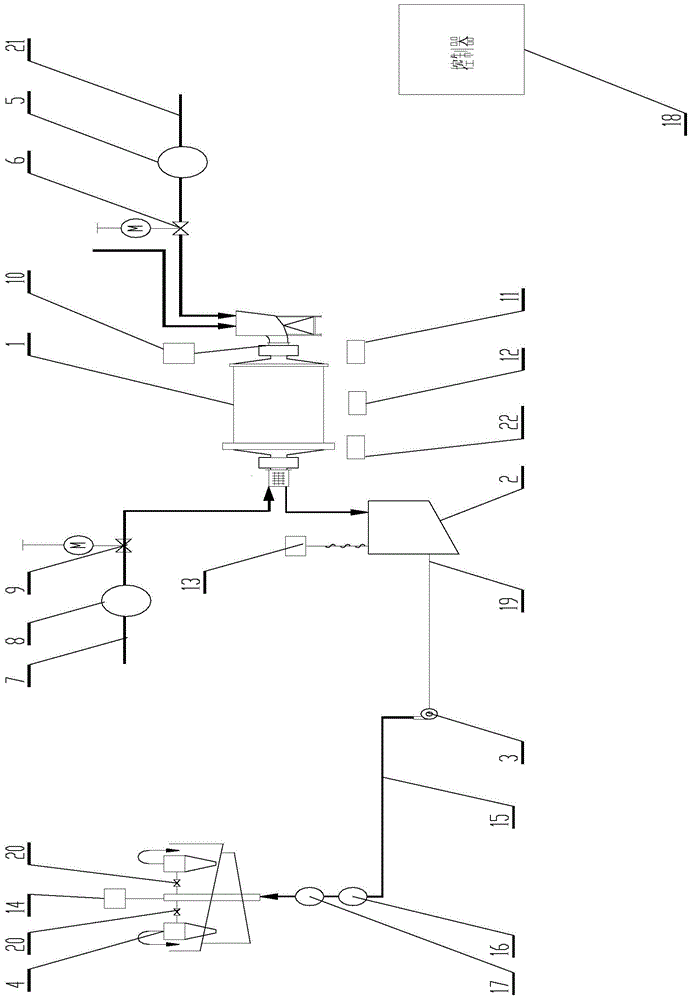

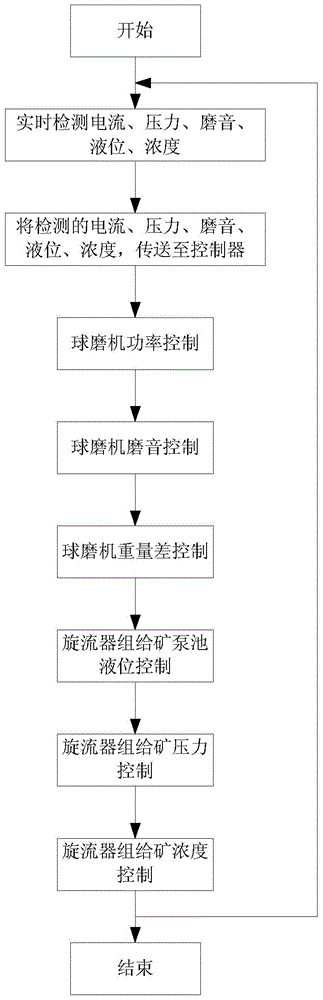

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, a closed-circuit control system of a ball mill-cyclone group, the technological process is that the pulp is fed into the ball mill 1 from the feeding end, the grinding product is automatically fed into the mine pump pool 2 of the cyclone group, and the pulp passes through the cyclone Group feed pipe 19 and cyclone group feed pump 3 feed into cyclone group 4, the bottom flow of cyclone group 4 flows back into ball mill 1, and the overflow of cyclone group feeds into the next stage of operation. The system includes a first flowmeter 5, a first regulating valve 6, a second flowmeter 8, a second regulating valve 9, an ammeter 10, a first pressure gauge 11, a second pressure gauge 22, an electric ear 12, and a liquid level gauge 13 , the third pressure gauge 14, the third flow meter 16, the concentration meter 17 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com