A kind of surfactant for preparing slow-resilient polyurethane foam and preparation process thereof

A surfactant and polyurethane foam technology, which is applied in the field of surfactants in the fine chemical industry, can solve the problems of poor rebound performance, uneven cell structure, and poor foam feel, and achieve stable foam and uniform Fine cell structure, the effect of improving the cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

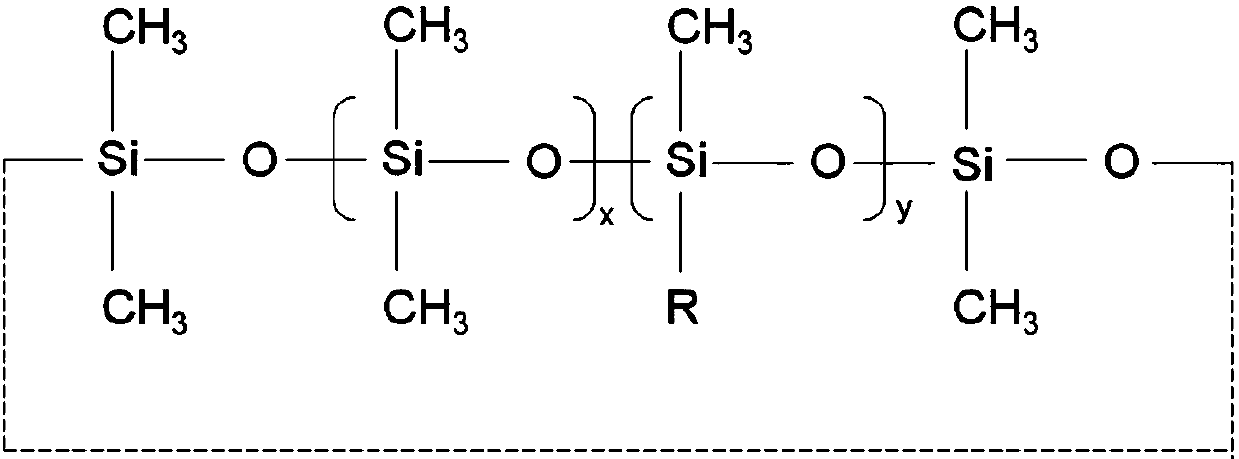

Method used

Image

Examples

Embodiment

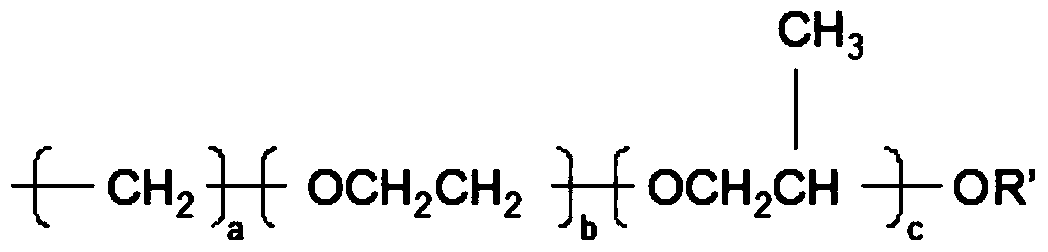

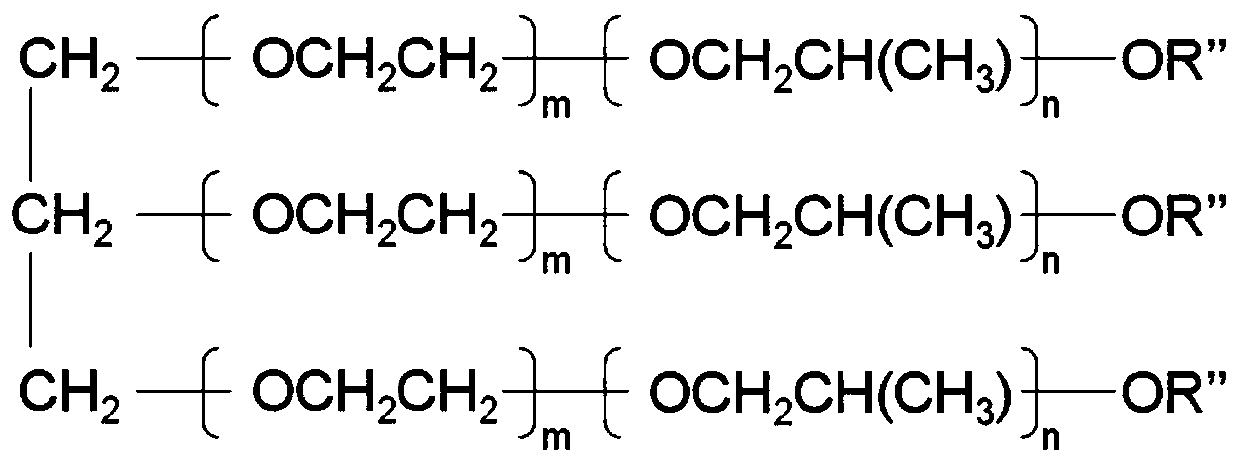

[0032] (1) Synthesis of propylene oxide and propylene oxide copolyether with allyl as the end group: add 1 to 10 parts by weight of allyl alcohol, 20 to 45 parts by weight of ethylene oxide and 50 ~70 parts by weight of propylene oxide, under the action of 0.1~0.5 parts by weight of basic catalyst, controlled reaction temperature 90°C~130°C, reaction pressure not greater than 0.5MPa, reacted for 4~6 hours, when the system pressure When the temperature is lowered to less than 0.15MPa, the temperature is lowered to stop the reaction. After neutralization, filtration and extraction, a ethylene oxide and propylene oxide containing allyl alcohol is obtained, with an allyl group at one end and a hydroxyl group at the other end. The polyether of the random copolymerization structure of the group.

[0033] Three polyether samples were synthesized according to this process, and the typical parameters of their molecular structures are as follows:

[0034] Table 1: Sample list of allyl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com