Production and construction technology of a road sealant

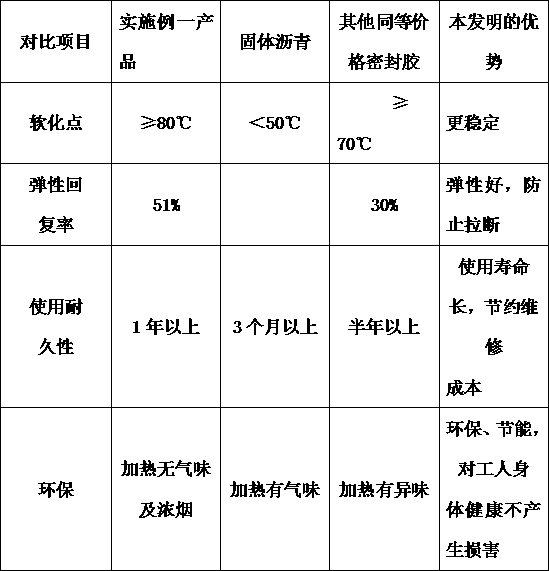

A sealant and road technology, applied in the direction of adhesive, adhesive type, adhesive additive, etc., can solve the problems of high maintenance cost, complex process, short service life, etc., and achieve low traffic noise, adhesiveness, and solution. The effect of stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

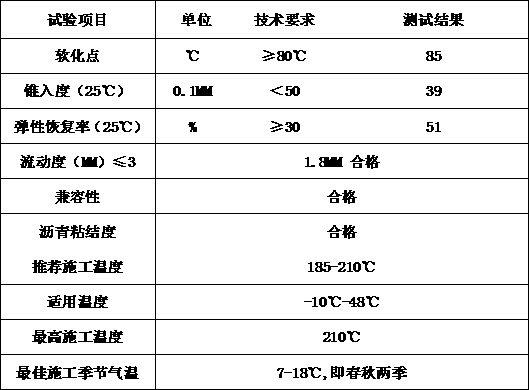

Examples

specific Embodiment approach

[0017] A road sealant, said sealant is mainly composed of 29% matrix asphalt by mass percentage, 15% fine rubber powder, 45% fossil powder, 0.4% SBS modified asphalt, 0.4% styrene-butadiene rubber powder, 0.1% active agent, 0.1% tackifier and 10% diesel.

[0018] A kind of production technology of road sealant: described production technology mainly comprises the following steps:

[0019] Step 1: Take the base asphalt according to the above ratio, put the base asphalt in the asphalt circulation tank, turn on the stirring function and the heating function, heat the base asphalt to 150-180°C evenly, then add talcum powder according to the above ratio and stir evenly;

[0020] Step 2: Take SBS modified asphalt, fine rubber powder and styrene-butadiene rubber powder according to the above ratio, put them in a mixing tank, heat them to a molten state, add active agent and tackifier in proportion and stir evenly;

[0021] Step 3: Add the mixture in the molten state in step 2 to the...

Embodiment 1

[0028] Embodiment 1: Adopt technology of the present invention to produce 1 ton of road sealant.

[0029] Get a kind of road sealant, described sealant is mainly by the mass percent of 0.29 tons of matrix asphalt, 0.15 tons of fine rubber powder, 0.45 tons of fossil powder, 0.04 tons of SBS modified asphalt, 0.04 tons of styrene-butadiene rubber Rubber powder, 0.01 tons of active agent, 0.01 tons of tackifier and 0.1 tons of diesel oil, put the base asphalt in the asphalt circulation tank, turn on the stirring function and heating function, and evenly heat the base asphalt to between 150-180 °C Then add talcum powder according to the above ratio and stir evenly; put SBS modified asphalt, fine rubber powder and styrene-butadiene rubber powder into the mixing tank, heat to molten state, add active agent and tackifier in proportion and stir evenly Add the mixture in molten state to the base asphalt in step 1, stir until fully mixed, then cool, and finally add diesel oil in propor...

Embodiment 2

[0030] Embodiment two: adopt technology of the present invention to produce 2 tons of road sealants.

[0031] Get a kind of road sealant, described sealant is mainly by the mass percent of 0.58 tons of matrix asphalt, 0.30 tons of fine rubber powder, 0.90 tons of fossil powder, 0.08 tons of SBS modified asphalt, 0.08 tons of styrene-butadiene rubber Rubber powder, 0.02 tons of active agent, 0.02 tons of tackifier and 0.2 tons of diesel oil, put the base asphalt in the asphalt circulation tank, turn on the stirring function and heating function, and evenly heat the base asphalt to between 150-180 °C Then add talcum powder according to the above ratio and stir evenly; put SBS modified asphalt, fine rubber powder and styrene-butadiene rubber powder into the mixing tank, heat to molten state, add active agent and tackifier in proportion and stir evenly Add the mixture in molten state to the base asphalt in step 1, stir until fully mixed, then cool, and finally add diesel oil in pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com