Biodegradable warp knitted filter material base cloth and preparation method thereof

A technology of biodegradation and manufacturing method, which is applied in the textile field to achieve the effects of strong tensile and deformation resistance, avoiding environmental pollution, and low regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

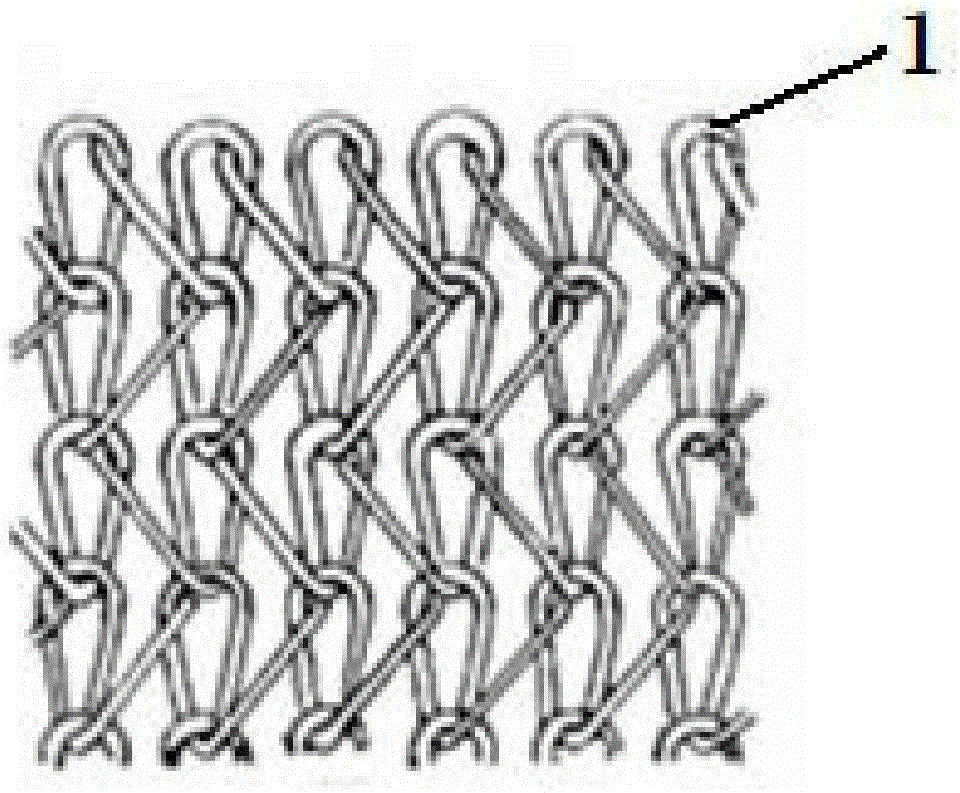

Image

Examples

Embodiment 1

[0030] Example 1 uses polylactic acid (PLA) as raw material, and 21SPLA yarn uses warp-knitted fabric to weave a warp-knitted base fabric. The steps are as follows:

[0031] 1. Warping: Take PLA superfine fiber with a monofilament density of 1.0dtex*38mm as raw material, spun into 21S knitting yarn to make cheese. Place the package yarn on the creel of the warping machine, and wind it into a warp beam in parallel, uniform speed and neatly under the same tension according to the number and length required by the warp knitting process.

[0032] Cheese specification: weight 6kg, yarn count 21S

[0033] 21SPLA yarn quality index

[0034] Item

Index

Yarn count (S)

21

Powerful (CN)

720

Strong CV value (%)

8.2

Elongation(%)

8.6

[0035] Warping with high-speed warping machine: 21SPLA cheese is placed on the creel equipped with tension and automatic stop when the yarn breaks. The PLA yarns drawn from the creel are arranged in a regular arrangement on the warp collecting board,...

Embodiment 2

[0056] Example 2 Using polybutylene succinate (PBS) staple fiber with a monofilament linear density of 1.2dtex*38mm as raw material, 16SPBS yarn was woven with warp knitting base fabric by warp weave, the steps are as follows:

[0057] 1. Warping: Using monofilament linear density 1.2dtex*38mm polybutylene succinate fiber staple as raw material, it is spun into knitted yarn and made into cheese. Place the package yarn on the creel of the warping machine, and wind it into a warp beam in parallel, uniform speed and neatly under the same tension according to the number and length required by the warp knitting process.

[0058] Cheese yarn specification: weight 6kg, yarn count 16S

[0059] 16SPBS yarn quality index

[0060] Item

Index

Yarn count (S)

16

Powerful (CN)

670

Strong CV value (%)

7.0

Elongation(%)

8.2

[0061] Warping with high-speed warping machine: 21SPBS cheese is placed on a creel equipped with tension and automatic stop when the yarn is broken. The PBS yarn ...

Embodiment 3

[0083] Example 3 uses polylactic acid (PLA) and polybutylene succinate (PBS) staple fibers as raw materials, and 21SPLA and PBS blended yarns are fabricated by warp knitting based on a flat weave. The steps are as follows:

[0084] 1. Warping: Polylactic acid (PLA) superfine fibers with a monofilament linear density of 0.8dtex*38mm and polybutylene succinate (PBS) staple fiber with a monofilament linear density of 1.0dtex*38mm as raw materials, blended The ratio is 50:50, and it is spun into 21S knitting yarn and made into cheese. Place the package yarn on the creel of the warping machine, and wind it into a warp beam in parallel, uniform speed and neatly under the same tension according to the number and length required by the warp knitting process.

[0085] Cheese specification: weight 6kg, yarn count 21S

[0086] 21SPLA, PBS blended yarn quality index

[0087] Item

Index

Yarn count (S)

21

Powerful (CN)

723

Strong CV value (%)

8.2

Elongation(%)

9.3

[0088] High-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com