Cast-in-place pile concrete interface recognition and super-cast loosening device and use method thereof

A technology for concrete and cast-in-place piles, which is applied to sheet pile walls, building structures, buildings, etc., can solve the problems of no treatment, difficulty in chiseling the top of cast-in-place piles, etc., so as to avoid waste and reduce difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by specific examples.

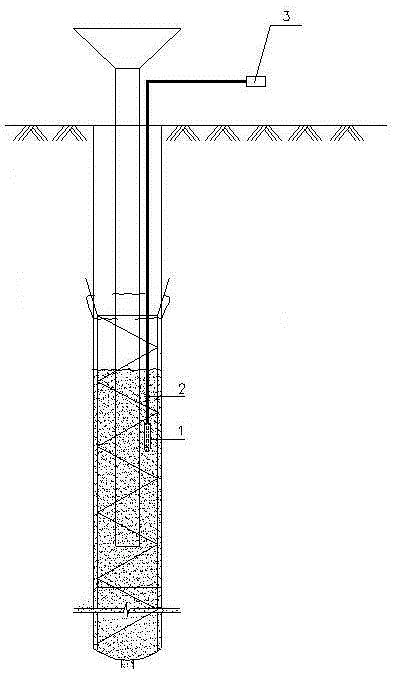

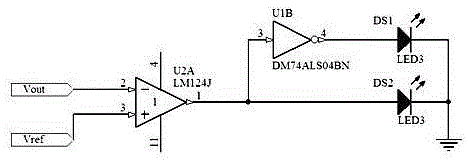

[0015] Such as figure 1 As shown, a concrete interface identification and superfill loosening device for cast-in-situ piles, it includes a vibration reflection head 1, a data line, an outer sheath pipe 2, a reflection wave receiver 3 and a control switch, the vibration reflection head 1, a data line, a reflection wave The wave receiver 3 and the control switch are connected by electrical signals in turn, and the outer sheath tube 2 is set outside the data line to play a protective role, and its two ends are respectively sealed and connected with the vibration reflection head 1 and the reflection wave receiver 3; the vibration reflection The head 1 includes a shell and a vibrating motor inside the shell. The reflected wave receiver 3 includes a signal processing chip and a display device. The data generated by the vibrating reflective head 1 is transmitted to the signal processing chip through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com