Multi-stage injection impact type turbine engine

A technology of turbine engine and impact turbine, which is applied to combined engines, engine components, machines/engines, etc., can solve problems such as the inability to work smoothly under variable load conditions, the inability to adapt to complex working conditions, and the lack of a low-power engine for the prime mover. Achieve major social and economic benefits, small footprint, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

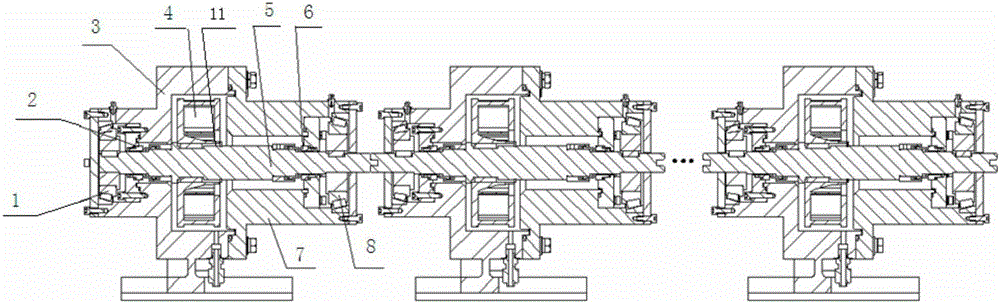

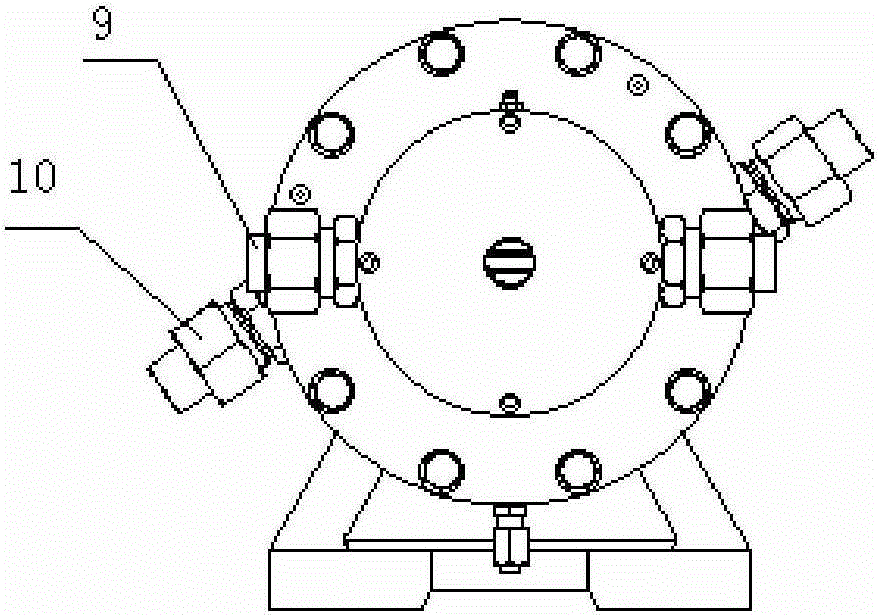

[0015] like figure 1 , 2 Shown, a kind of multi-stage injection impingement turbine engine comprises a plurality of turbine engines connected in series, the exhaust pipe 9 of the previous stage turbine engine in the adjacent two turbine engines is connected to the nozzle 10 of the next stage turbine engine, and the adjacent The ends of the rotating shafts 5 of the two turbine engines are matched and connected with each other, the nozzle 10 of the first-stage turbine engine is connected to the pipeline of the steam generator; the end of the rotating shaft of the last-stage turbine engine is connected to the main shaft of the generator to drive the generator to generate electricity. The turbine engine comprises a housing 3, a nozzle 10, a rotating shaft 5, a moving impeller 4, a mechanical seal a2, a mechanical seal b6, a bearing a1 and a bearing b2, and the housing is a two-part housing a, housing b; there are two nozzles 10 with an angle of 35° with the horizontal plane, symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com