Air filtering device of engine

An engine and air filter technology, which is applied in the field of air filters, can solve the problems of high noise of air filters, achieve the effects of reducing noise pollution, easy installation and use, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

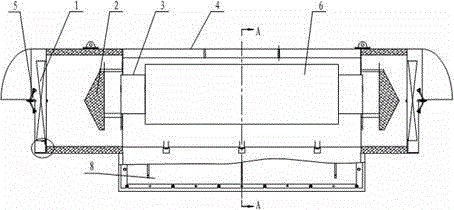

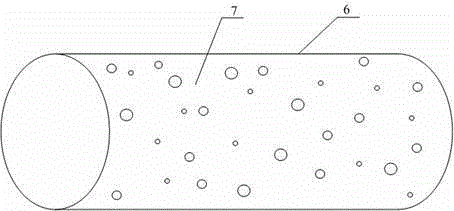

[0018] like figure 1 The shown engine air filter device includes an outer cylinder 4 with two air inlets and several air outlets, a filter element 1 installed behind each air inlet, a filter element fixing device 5, a splitter cap 2 and a vent pipe 3. A resonant cavity 6 is installed inside the outer cylinder 4, and the shell of the resonant cavity 6 is made of a thin metal plate material 7 with circular perforations. The metal sheet material 7 with circular perforations has a circular perforation diameter of 1-3 mm and is randomly distributed. The metal material has high strength, high temperature resistance, long service life, and is not easily damaged, and is preferably galvanized sheet, aluminum sheet or stainless steel sheet. Compared with rectangular or polygonal perforations, circular perforations can increase the flow area and prevent air from being compressed and accumulated in the resonance cavity. During the working process, the air enters from the air inlet, is f...

Embodiment 2

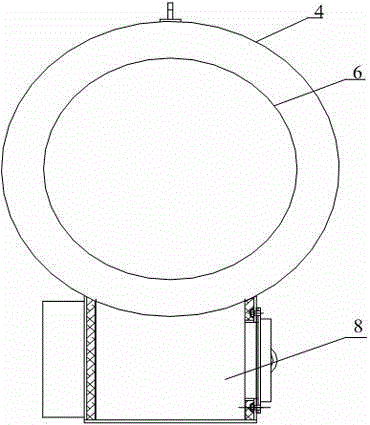

[0020] An engine air filter device, on the basis of Example 1, the inner side of the outer cylinder 4 and the outer side of the air pipe 3 are covered with a layer of the metal sheet material 7 with circular perforations, and the outer cylinder 4 is fixed on the base 8. Utilizing the natural frequency of the metal sheet 7 with circular perforations in the same range as the sound wave frequency of the air filter noise, the metal sheet material resonates, thereby further weakening the sound wave energy in the entire air filter and reducing the direct impact of the penetrating outer cylinder. The sound wave energy transmitted outside the air filter achieves the purpose of reducing noise. The outer cylinder 4 is fixedly placed on the base 8 to reduce shaking of the outer cylinder caused by resonance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com