Recognition device of wind power blade surface faults

A technology for identifying devices and blades, used in wind power generation, wind turbine components, wind turbine control, etc., can solve problems such as failure of wind turbine equipment, economic losses in wind farms, and increase in problem accumulation, reducing downtime for maintenance. time, increase economic efficiency, improve the effect of running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

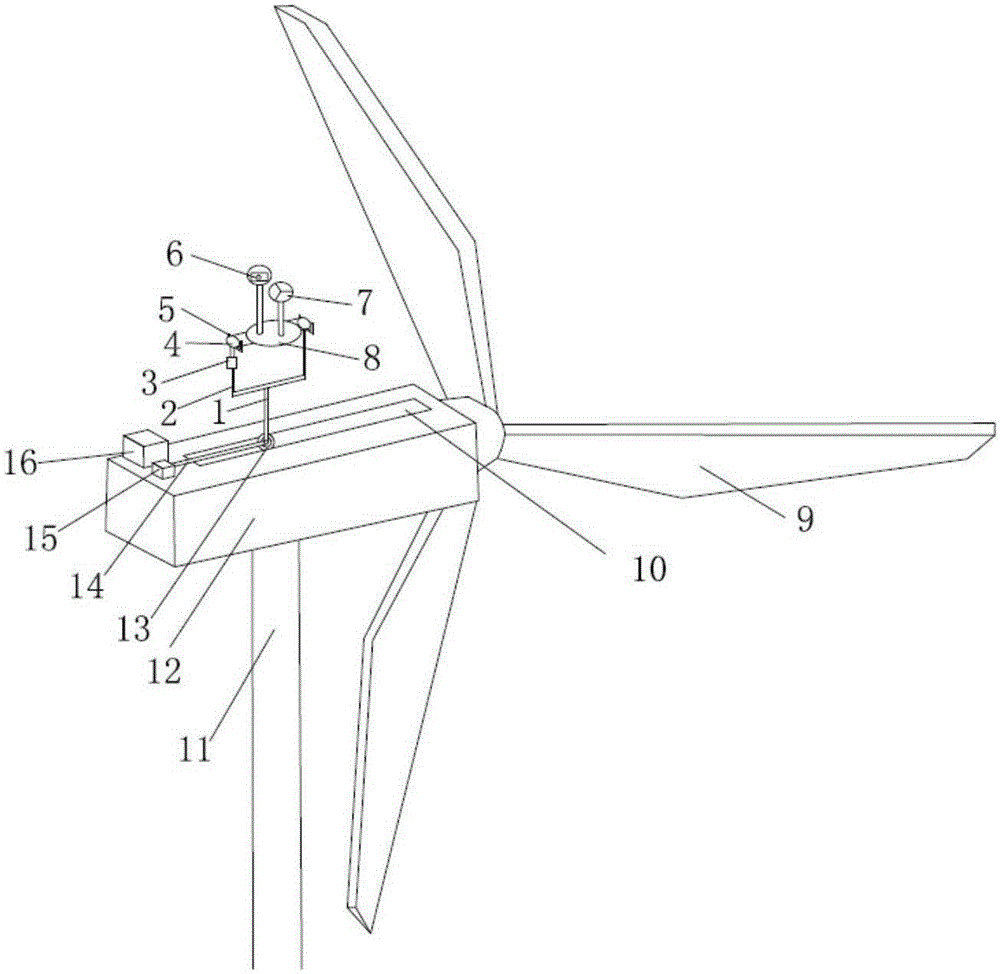

[0019] Such as figure 1 As shown, the identification device for a surface fault of a wind power blade provided by the present invention includes a nacelle 12 arranged on the top of a column 11, the front end of the nacelle 12 is provided with a fan blade 9, and the upper top surface of the nacelle 12 is provided with There is a hydraulic device 15 connected with the controller 16, the push rod 14 of the hydraulic device 15 is connected with the roller 13 arranged on the slide rail 10, the roller 13 is fixed with a pole 1, and the pole 1 is fixed Connected to the bottom of the first U-shaped bracket 2, the two ends of the opening of the first U-shaped bracket 2 are respectively connected to the bottom of the second U-shaped bracket 5, and the openings of the two second U-shaped brackets 5 are movable Connected with a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com