Water sample collection system and water sample collection method for sampling from pressurized wells

A collection system and pressurized well technology, applied in the direction of sampling devices, etc., can solve the problems of low fidelity of water samples containing environmentally sensitive substances, inconvenient installation and operation of collection devices, etc., to reduce the probability and speed change of volatile substances precipitation Smooth, low-perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

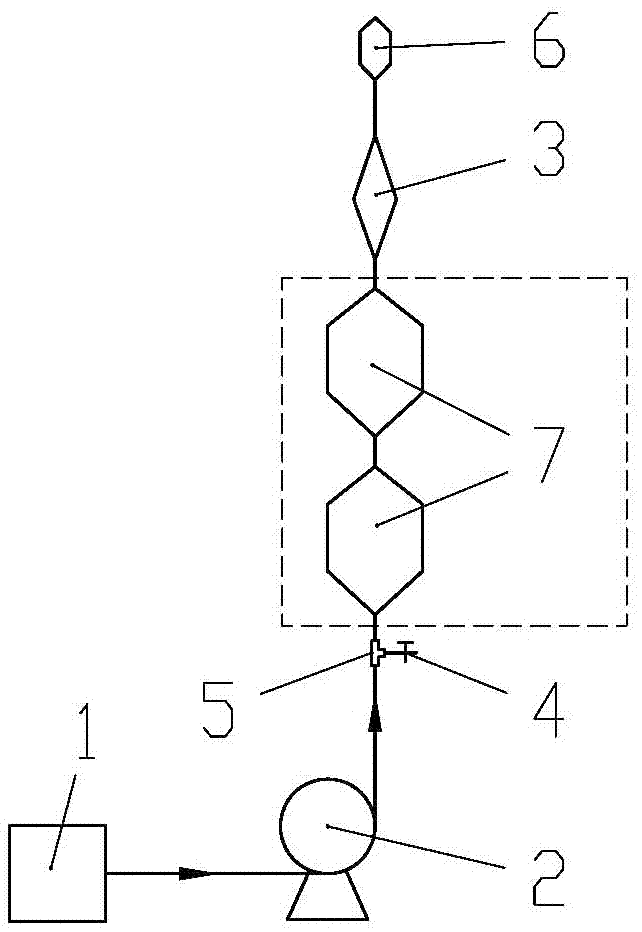

[0042] Such as figure 1 Shown, the water sample collection system of the present invention comprises the wellhead connection sampling device 1 that is arranged on the wellhead of the pressurized well, the output port of the wellhead connection sampling device 1 is connected to the input port of the self-priming pump 2 through a flexible pipe, and the self-priming pump 2 The output port is connected to the tee 5 through a pipeline, and the upper port of the tee 5 is connected to two series-connected expansion tube filters 7 through a pipeline, and the upper port of the upper expansion tube filter 7 is connected to the mass stabilizer 3 through a pipeline. The input port is connected to the bypass port of the tee 5 with the diversion control valve 4, and the output port at the upper end of the mass stabilizer 3 is connected to the split combined sampling bottle 6 through a pipeline.

[0043] The expansion tube filter 7 is an optional part in the water sample collection system, a...

Embodiment 2

[0053] A water sample collection method for sampling from a pressurized well, comprising the following steps:

[0054] 1. The construction of the water sample collection system: first use a glass bottle to take a small amount of water from the pressurized well to be sampled and observe the water quality of the water. , the diversion control valve 4 and the mass stabilizer 3 are assembled and connected to form the main body of the water sample collection system; The device 3 and two expansion tube filters 7 are assembled and connected to form the main body of the water sample collection system. The mass stabilizer 3 should be adjusted to be vertically arranged above the output port of the self-priming pump 2, and the expansion tube filter 7 is connected below the mass stabilizer 3 and is on a vertical line with the mass stabilizer 3.

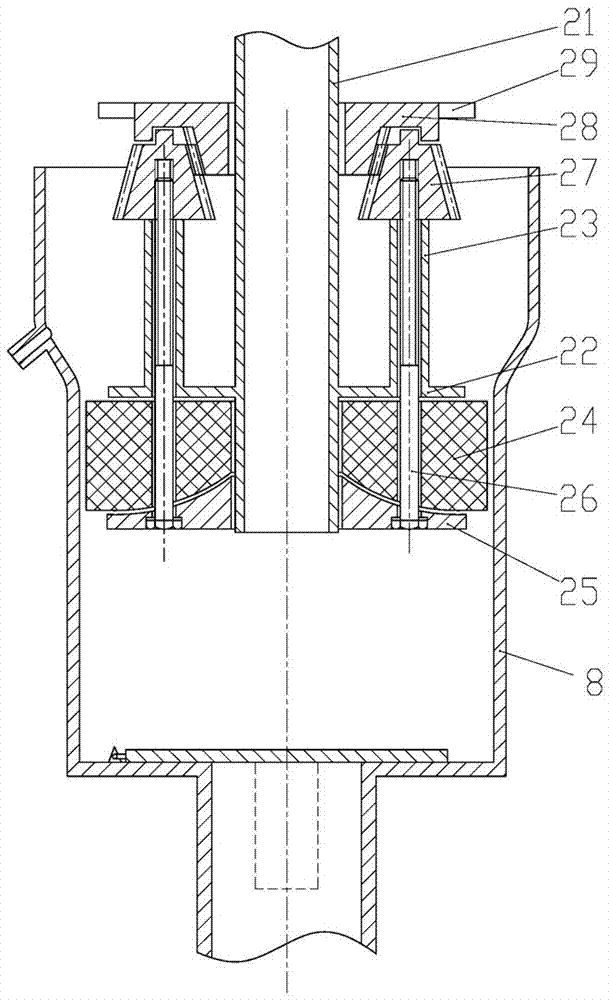

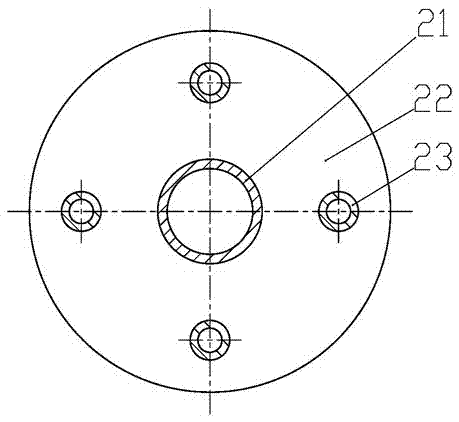

[0055] 2. Take off the pressure handle and the water lifting mechanism on the wellhead 8 of the pressure water well to be sampled, install and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com