Sealing structure for pipeline connector of R744 air conditioner heat pump system

A heat pump system and sealing structure technology, applied in the direction of hose connection device, non-removable pipe connection, pipe/pipe joint/pipe fitting, etc. The deformation is not uniform enough to achieve the effect of improving the scope of use, the accuracy of the parts is not high, and the repeated installation of the pipeline is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

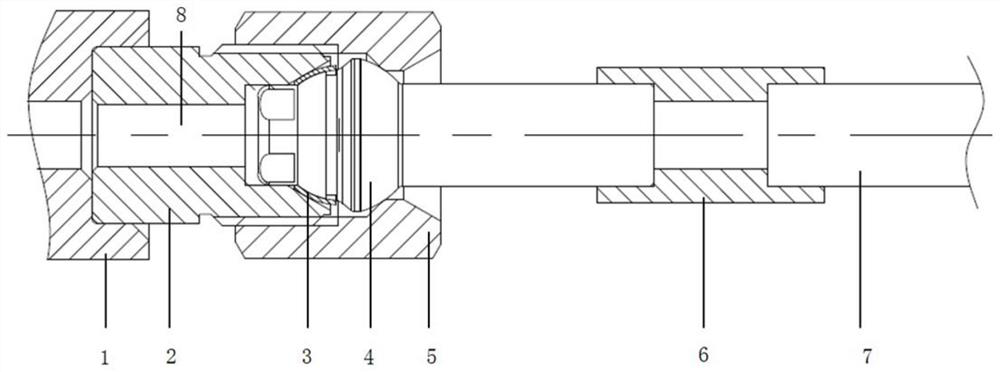

[0027] The invention relates to a sealing structure for the pipeline interface of the R744 air-conditioning heat pump system. Compared with the current R744 (C02) air-conditioning pipe pressure plate adopting the eccentric compression metal gasket seal on the end face of the pressure plate, the structure of the present invention adopts the axial compression of the ball head The metal gasket seal can make the gasket turnover compression even.

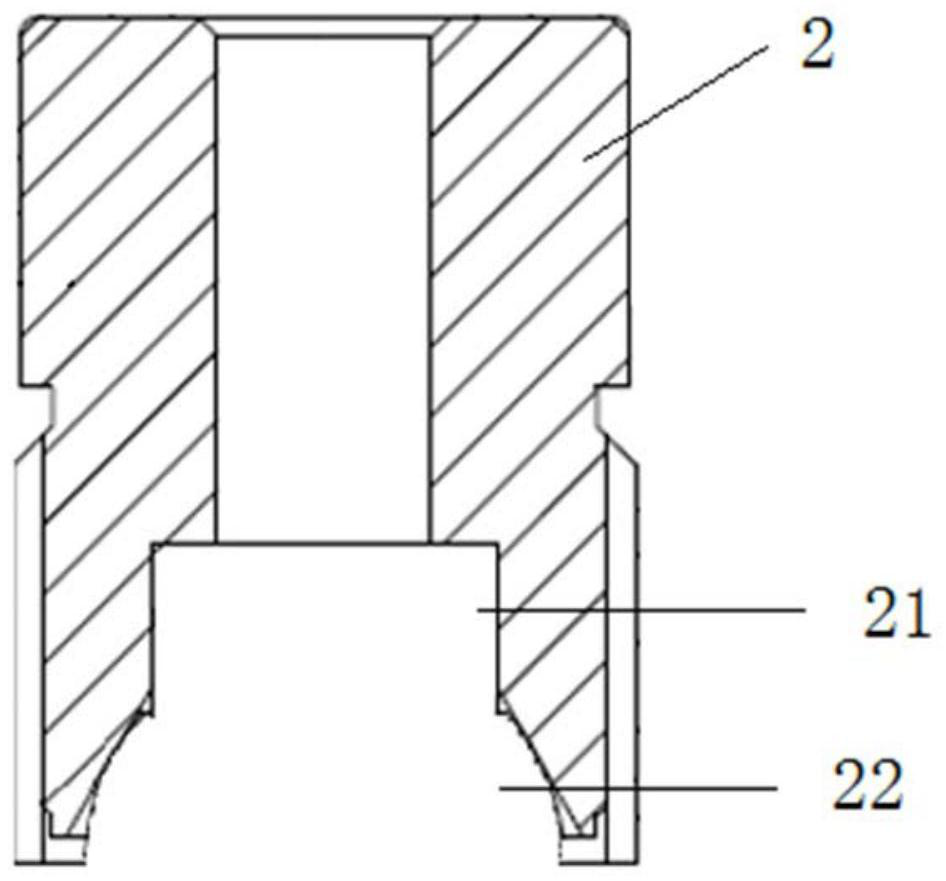

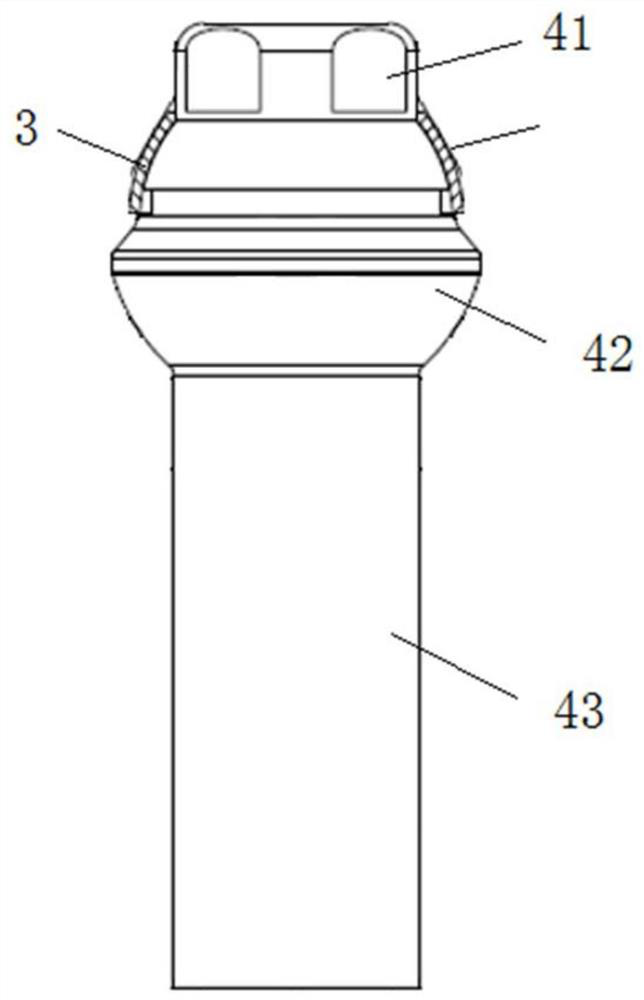

[0028] The structure of the sealing structure of the present invention is as figure 1 As shown, it includes: an air-conditioning pipe counterpart 1, a connecting piece 2, a metal spherical gasket 3, a spherical joint 4, a nut 5, a transition joint 6 and an air-conditioning hard pipe 7.

[0029] The air-conditioning pipe counterpart 1 is set outside the air-conditioning hose 8, the air-conditioning pipe counterpart 1 is connected to the ball joint 4 through the connecting piece 2, and the air-conditioning hose 8 protrudes from the air-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com