High-density optical fiber arranging frame

A cable management rack and high-density technology, which is applied in the field of optical communication equipment, can solve the problems of inconvenient search and arrangement of melted pigtails, inability to meet the requirements of optical fiber maintenance and management, and restrictions on the location of fiber output and cable entry, achieving compact structure and low operating costs. Reasonable cost and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

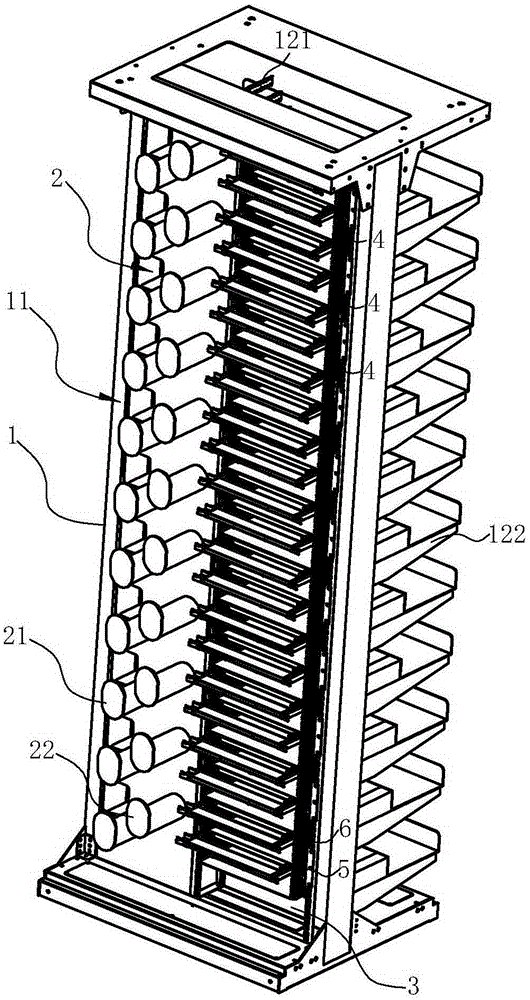

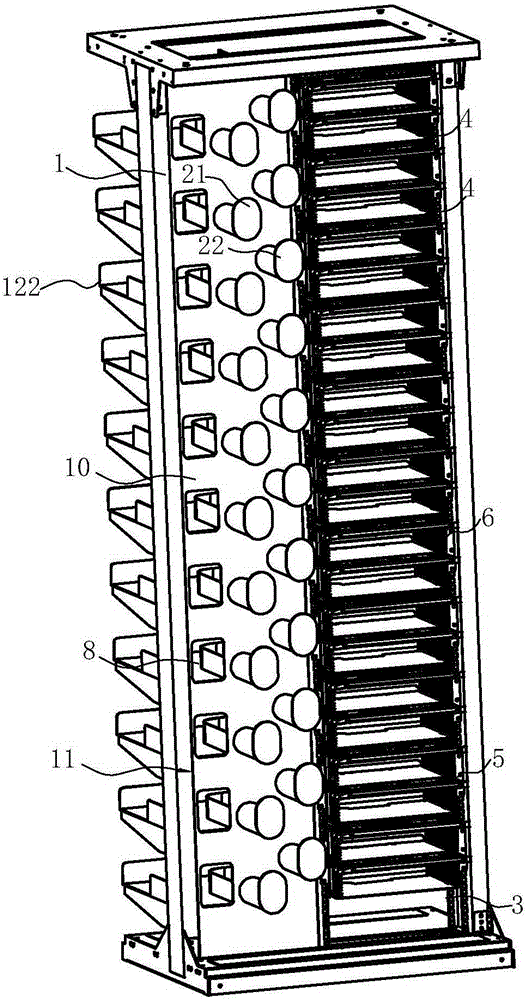

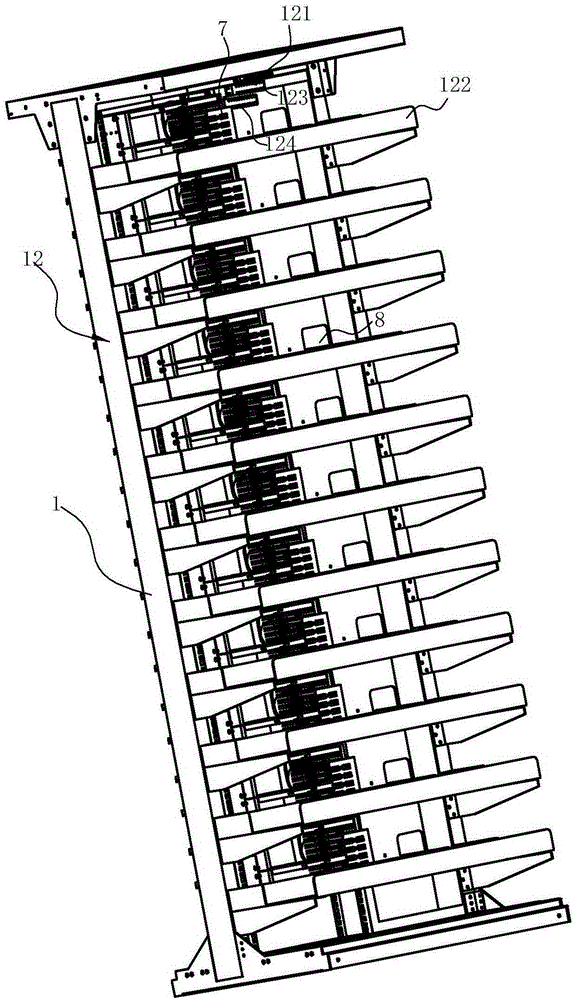

[0023] Such as Figure 1-9 As shown, the high-density optical fiber cable management rack includes a frame 1, and the frame 1 includes a front structure 11 and a back structure 12, wherein the front structure 11 includes a fiber storage device 2 and an optical fiber fusion tray 5 unit boxes 3, and the optical fiber fusion The fiber tray unit box 3 is located on the right side of the entire rack 1, while the fiber storage device 2 is located on the left side of the entire rack 1, including two rows of first fiber winding columns 21 and second fiber winding columns arranged staggered from each other Group 22, the back structure 12 includes an optical cable introduction fixing device 121 and a cable management slot 122, and the other side of the second winding column group 22 is provided with a plurality of channels for the fused optical cables t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com