Operational process and troubleshooting training system and method for water-pumping and energy-storage machine set

A technology for pumped storage units and fault finding, which is applied in the general control system, control/regulation system, program control, etc., and can solve the problem that the training effect is difficult to meet expectations, it is difficult to quickly improve the fault finding ability, and there are few opportunities for on-site fault finding and other problems, to achieve the effect of rich display screen and improved fault finding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

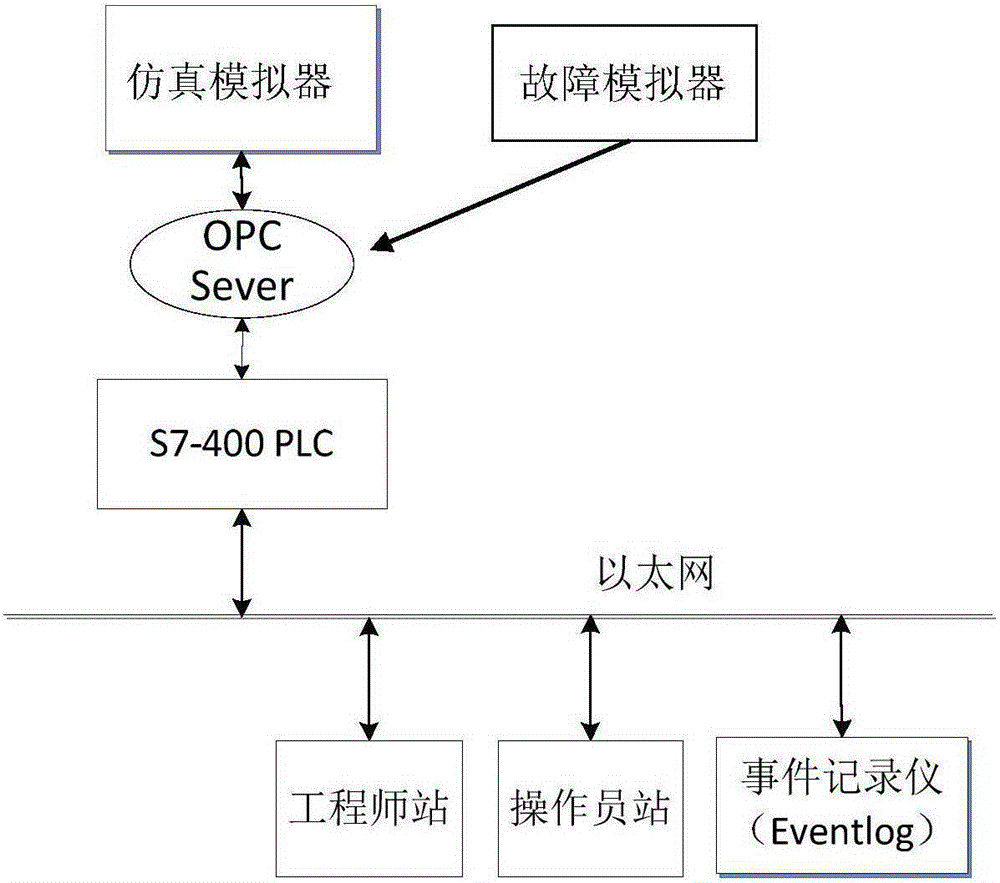

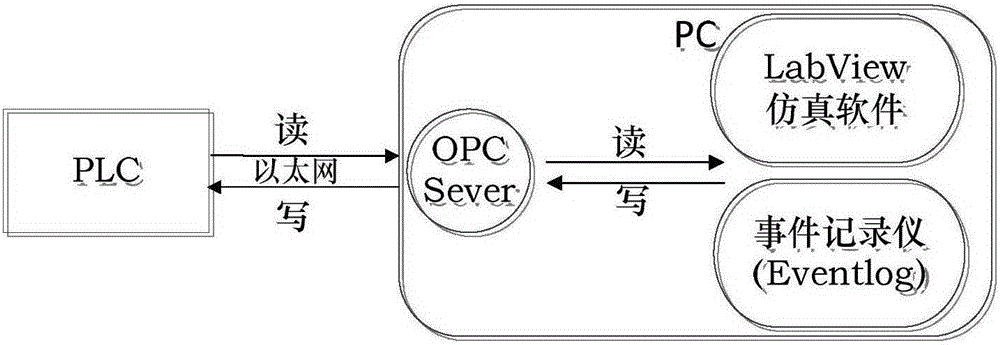

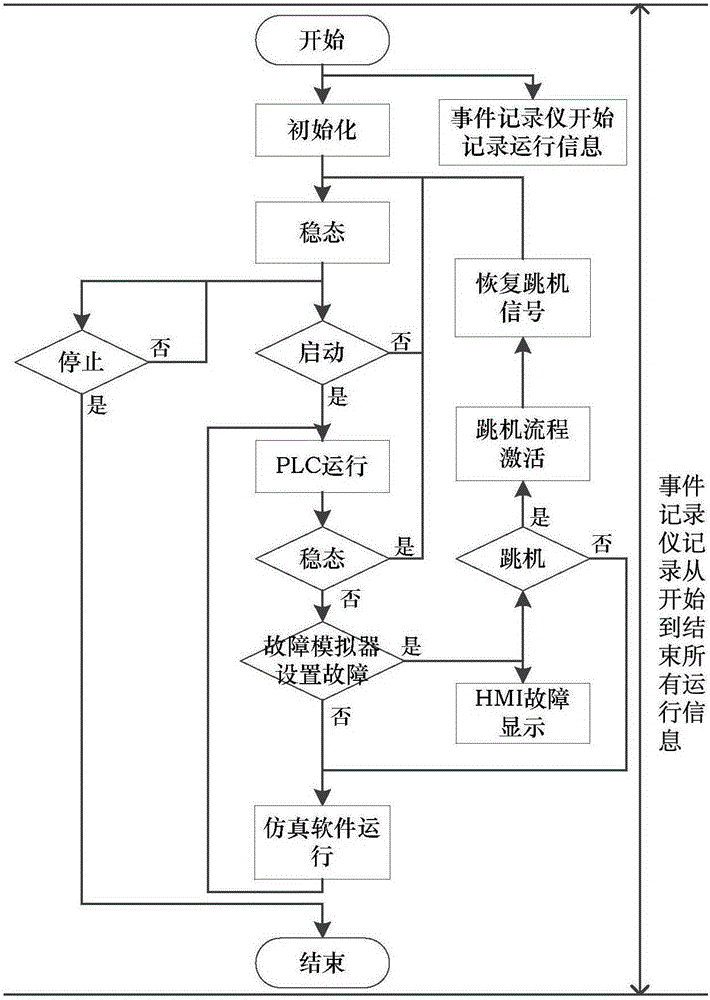

[0049] Such asfigure 1 As shown, a pumped storage unit control program training system, including:

[0050] The local control unit (LCU) adopts the physical programmable logic controller (PLC) to download and run the control program of the unit;

[0051] The engineer station is used to complete the configuration of the application software and the work related to the composition of the control system;

[0052] The operator station provides a man-machine interface to complete the unit control program control. It can also display the control flow of the unit, the dynamics of the operation screen of the main equipment, the action of each switch in the electrical circuit and the change of the main parameters, etc.

[0053] The event recorder (Eventlog) records the action signals, fault signals and events of each device during the operation of the unit.

[0054] Simulation simulator, the simulation simulator is equipped with Labview simulation simulation software, and uses corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com