Touch screen, display device and display driving method of display device

A technology of a display device and a touch screen, which is applied to the touch screen, the display device and the display driving field of the display device, can solve the problems of disconnection, disconnection, and large thickness of the touch electrode, and achieve the effect of reducing the thickness and avoiding the disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

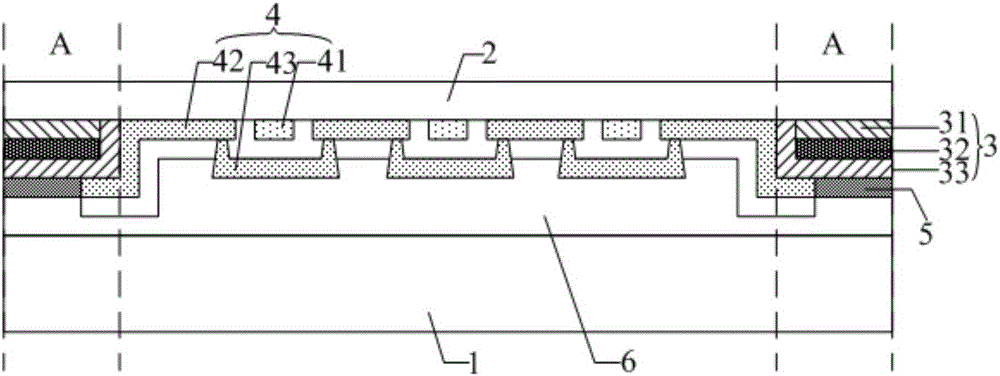

[0058] Example 1: The resistance change sensor detects whether the resistance of the low-reflectivity conductive layer changes when the power button is pressed for 2s to 3s.

[0059] In specific implementation, in the above-mentioned display device provided by the embodiment of the present invention, such as Figure 4 As shown, it may also include: a power key 404 for controlling the touch screen 401 to be turned on or off; when the resistance change sensor 402 senses that the resistance changes, that is, when the touch function of the touch screen 401 is abnormal, the resistance change sensor 402 outputs to the drive circuit 403 The first control signal controls the driving circuit 403 to drive the display panel to display the first display interface. Preferably, the first display interface displays an option: press and hold the power button for 5s to 6s to dial an emergency call. In this way, not only can it be judged Whether the touch function of the touch screen is normal ...

example 2

[0061] Example 2: The resistance change sensor senses in real time whether the resistance of the low-reflectivity conductive layer changes.

[0062] In specific implementation, in the above-mentioned display device provided by the embodiment of the present invention, such as Figure 4As shown, it may also include: a power key 404 for controlling the touch screen 401 to be turned on or off; when the resistance change sensor 402 senses that the resistance changes, that is, the touch function of the touch screen 401 is abnormal, the implementation is similar to the situation in Example 1. This will not be described in detail; when the resistance change sensor 402 does not sense a change in resistance, that is, when the touch function of the touch screen 401 is normal, the resistance change sensor 402 outputs a second control signal to the driving circuit 403, and the driving circuit 403 is controlled to drive the display panel to display the second control signal. The second disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com