Display substrate and manufacturing method thereof and display device

A technology for displaying substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor adsorption and detachment between flat layers and transparent conductive layers, so as to ensure performance and increase adhesion , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

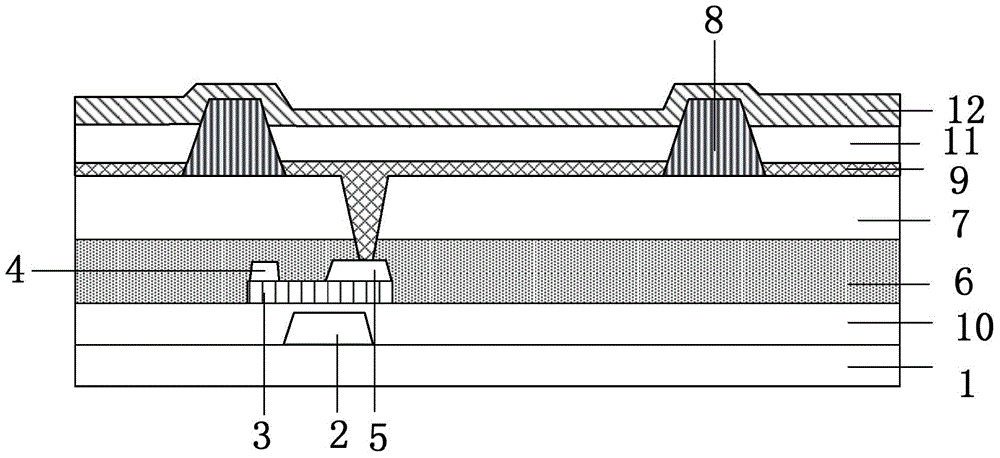

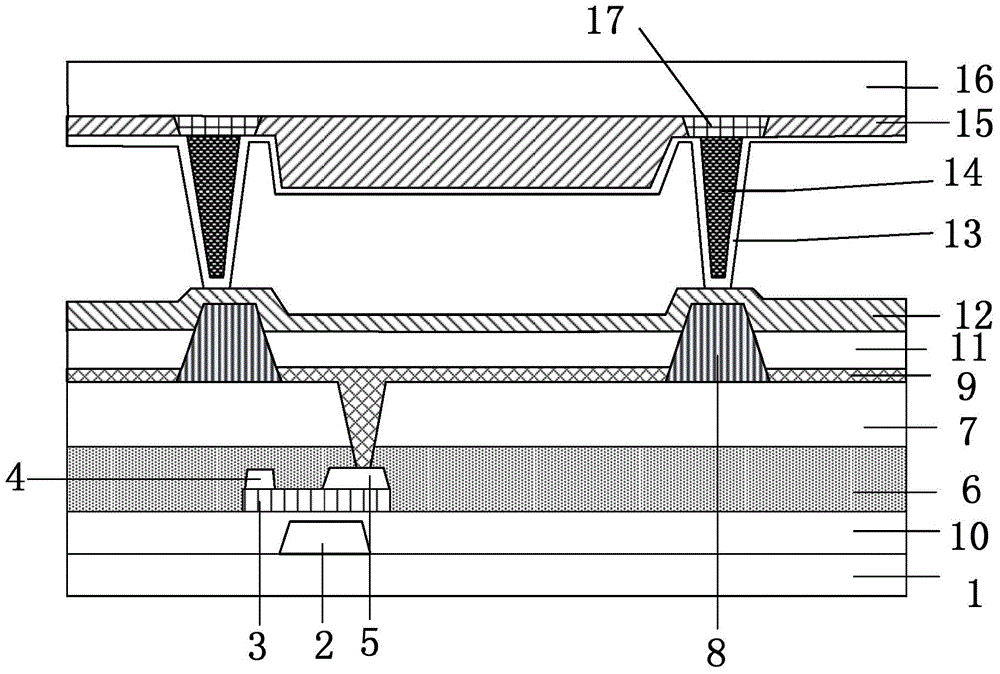

[0017] The present invention provides a display substrate, including a flat layer for providing a platform surface, the material of the flat layer includes organic silicon, because organic silicon has both the properties of organic materials and inorganic materials, so that the flat layer and the organic material thin film and The inorganic material film has good adhesion, prevents the flat layer from peeling off from adjacent films, ensures the performance of the display substrate, and improves product quality.

[0018] Among them, organosilicon is an organosilicon compound, which refers to a compound containing Si-C bonds, and at least one organic group is directly connected to a silicon atom. Compounds in which atoms are linked are also referred to as organosilicon compounds. Among them, the polysiloxane composed of silicon-oxygen bond (-Si-0-Si-) as the skeleton is the most numerous, the deepest researched and the most widely used class of organosilicon compounds, accounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com